The global demand for high-quality materials in various industries has driven the rise of innovative solutions like the Hollow Board Backing Plate. As reported by recent industry analyses, the construction and manufacturing sectors are projected to grow at a compound annual growth rate (CAGR) of over 5% from 2023 to 2028, significantly augmenting the need for sustainable and durable components. The Hollow Board Backing Plate, with its lightweight and robust structure, not only supports efficient logistics but also enhances product longevity, making it an essential choice for manufacturers seeking to optimize their supply chains. Furthermore, China's role as a leading producer of these backing plates underscores its commitment to quality manufacturing, positioning it as a preferred partner for global buyers. This blog will delve into the advantages and applications of the best Hollow Board Backing Plates, providing insights for decision-makers looking to make informed choices in an increasingly competitive market.

Hollow board backing plates have gained significant traction across various industries due to their unique combination of strength, lightweight properties, and cost-effectiveness. According to a report by Smithers Pira, the global demand for hollow board materials is projected to grow at a compound annual growth rate (CAGR) of 5.6% through 2025. This growth is fueled by the material's versatility, making it ideal for applications ranging from packaging to construction. These plates are particularly favored in the packaging industry for protective cushioning, as they reduce overall weight while maintaining structural integrity.

Hollow board backing plates have gained significant traction across various industries due to their unique combination of strength, lightweight properties, and cost-effectiveness. According to a report by Smithers Pira, the global demand for hollow board materials is projected to grow at a compound annual growth rate (CAGR) of 5.6% through 2025. This growth is fueled by the material's versatility, making it ideal for applications ranging from packaging to construction. These plates are particularly favored in the packaging industry for protective cushioning, as they reduce overall weight while maintaining structural integrity.

In the signage and display sector, hollow board backing plates are becoming increasingly popular. A study by Grand View Research states that the global sign and display market is expected to reach $24.5 billion by 2027, with a significant share attributed to lightweight materials like hollow boards. Their ability to provide excellent print quality and resistance to moisture makes them a preferred choice for outdoor advertising and temporary installations. Furthermore, the recycling aspect of hollow board materials aligns with the growing demand for sustainable practices in various industries, thereby enhancing their appeal among environmentally-conscious buyers.

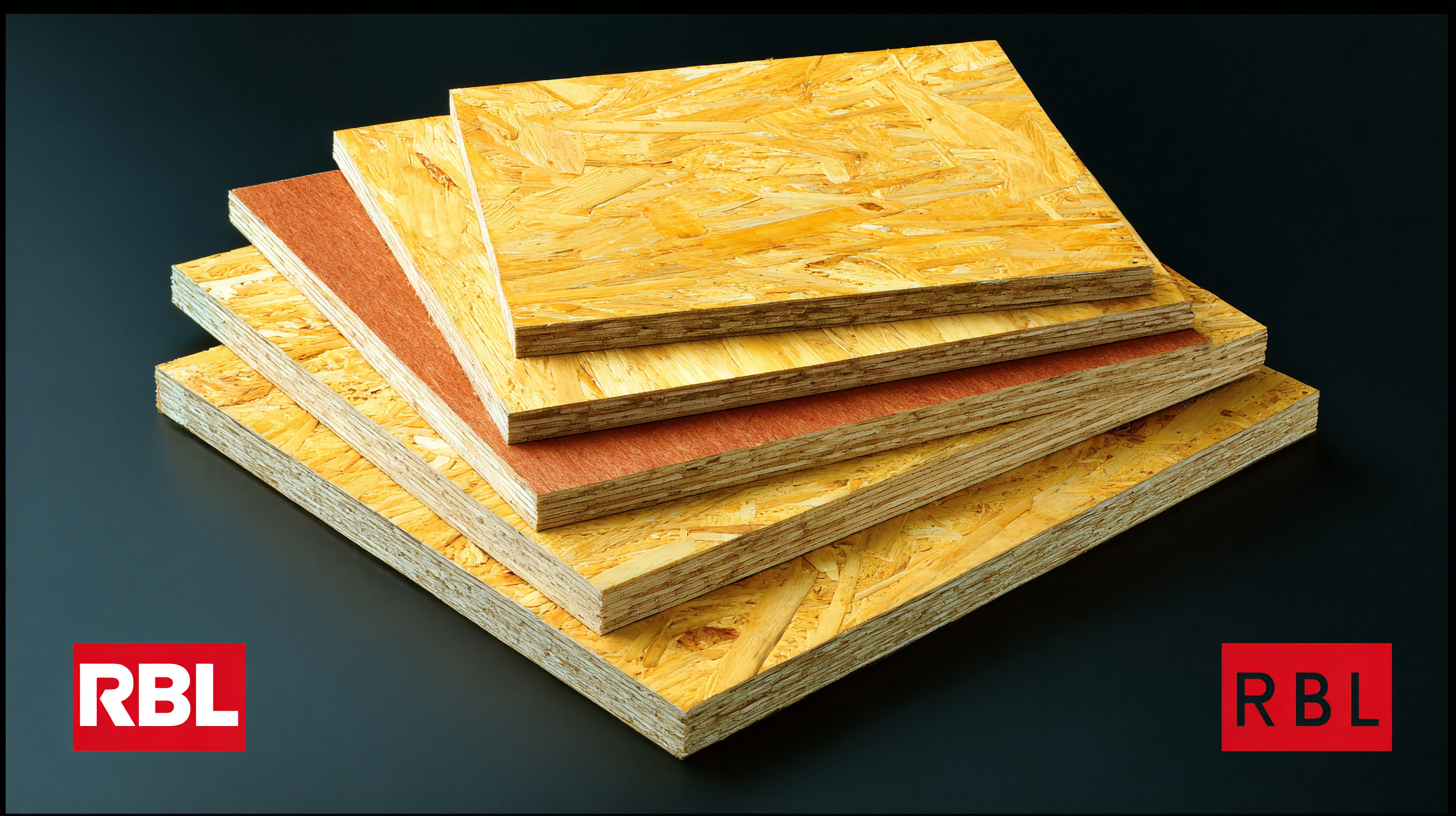

When considering hollow board backing plates, it's essential to understand the different types available on the market and their unique features. One of the most popular options is the polypropylene hollow board, known for its lightweight yet durable characteristics. This type is often employed in packaging and protective cases, thanks to its resistance to moisture and chemicals. Additionally, its flexibility allows it to be easily shaped, making it ideal for customized applications.

Another noteworthy option is the corrugated hollow board, which provides enhanced structural integrity due to its layered design. Often used in construction and industrial settings, this type can support heavier loads while still maintaining a low weight. Its excellent thermal insulation properties also make it a favorite for HVAC applications. Buyers should consider the specific requirements of their projects when choosing between these options, as each type of hollow board backing plate offers distinct advantages that can fulfill varied needs.

When choosing backing plates, global buyers must consider several key factors to ensure they are investing in the best hollow board options available. One significant consideration is the material composition of the backing plate. Reports indicate that composites, such as polypropylene and polyethylene, account for a substantial market share due to their lightweight and durable properties. This is particularly advantageous in sectors such as advertising and automotive, where performance and cost-effectiveness are crucial.

Another vital aspect to consider is the environmental impact of the backing plates. According to industry studies, around 60% of consumers prefer eco-friendly products, prompting manufacturers to innovate sustainable solutions. Buyers should look for plates that are recyclable and made from post-consumer materials. Also, certifications like ISO 14001 can be a valuable indication of a company's commitment to environmental sustainability.

Tips: When assessing potential suppliers, request samples to evaluate the product's quality firsthand. Engaging in discussions about manufacturing processes can provide insights into how the plates are made and their environmental impacts. Additionally, considering the supplier's reputation and customer feedback is essential in making a well-informed decision.

Hollow board materials have gained traction in recent years due to their notable sustainability and cost-effectiveness. These innovative backing plates are crafted from recycled plastics or other eco-friendly substances, making them a superior alternative to traditional materials. By utilizing renewable resources and focusing on recyclability, hollow boards significantly reduce the environmental impact associated with production and disposal. This aligns with the growing consumer demand for sustainable practices among manufacturers and suppliers alike.

The cost-effectiveness of hollow board backing plates further enhances their appeal to global buyers. Their lightweight design not only reduces shipping costs but also minimizes energy consumption during transportation. Additionally, the durability and strength of hollow boards ensure long-lasting use, which means less frequent replacements and lower overall material investments. By integrating hollow board solutions into their operations, businesses can enjoy a dual benefit: contributing to environmental conservation while also optimizing their budget. This combination makes hollow board materials an attractive choice for industries ranging from packaging to construction, helping them achieve both sustainability and economic efficiency.

Hollow board backing plates are becoming increasingly popular in various industries due to their lightweight yet durable design. These plates are particularly advantageous in packaging and construction, where strength-to-weight ratio is crucial. In real-world scenarios, they are used for creating protective barriers, insulating materials, and even display boards. Their versatility extends to applications in outdoor events and exhibitions, where they serve as sturdy yet portable solutions for stand setups.

When considering the use of hollow board backing plates, it’s important to keep a few tips in mind. First, ensure that you select the right thickness to match the demands of your project—thicker boards often provide better durability without adding excessive weight. Additionally, think about customizing the backing plates with printed designs or branding, which can enhance their functionality, especially for promotional events.

Moreover, these backing plates are easy to work with, allowing for quick assembly and disassembly. This feature makes them ideal for temporary installations, like exhibits or special outdoor events. Always make sure to store them properly to maintain their integrity over time, and regularly inspect for any signs of wear or damage after extensive use.

| Application Area | Advantages | Material Types | Common Uses |

|---|---|---|---|

| Packaging | Lightweight, strong, and durable, reducing transport costs | Polypropylene, recycled materials | Shipping containers, point of sale displays |

| Construction | Water-resistant and mold-resistant, lightweight construction | Expanded polystyrene, eco-friendly composites | Temporary structures, insulation panels |

| Advertising & Displays | Versatile and easy to print on, good visibility | PET, cardboard | Banners, promotional stands, trade show displays |

| Automotive | Exceptional impact resistance and lightweight features | Hollow polypropylene, lightweight composites | Interior panels, packaging for parts |

| Furniture | Cost-effective, strong support while remaining lightweight | Recycled cardboard, engineered plastics | Furniture backs, shelving, partitions |