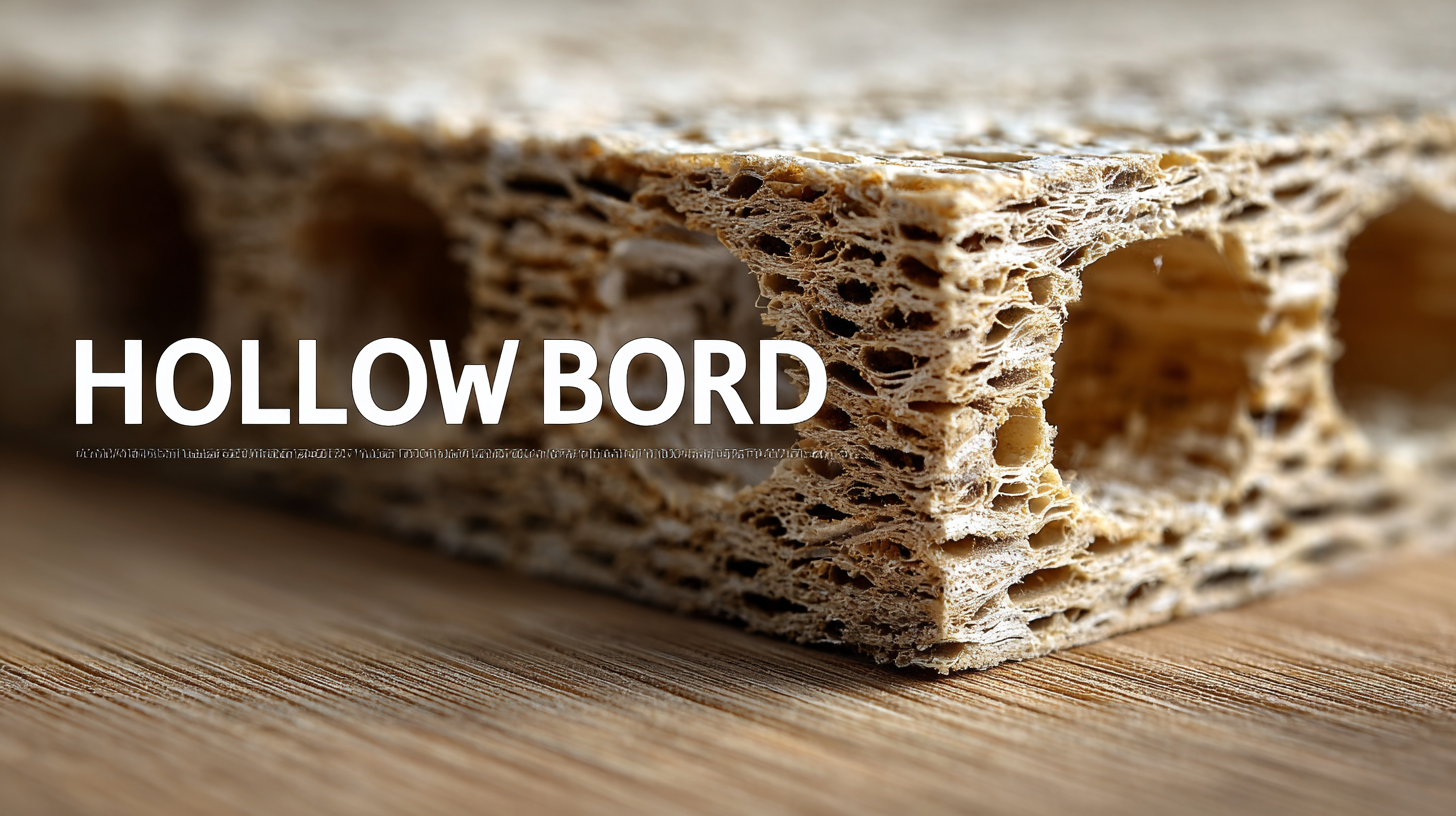

When it comes to optimizing your business operations, selecting the right materials is crucial, and one such material that stands out is the Hollow Board. Known for its lightweight yet robust structure, Hollow Board has become increasingly popular across various industries, from packaging to construction. However, with a myriad of options available on the market, choosing the best Hollow Board tailored to your specific business needs can be a daunting task. Understanding the industry production standards and how they apply to your selections is paramount. In this blog, we will explore seven essential tips that will guide you in making an informed decision, ensuring that you not only meet regulatory requirements but also enhance the efficiency and effectiveness of your operations. Whether you are a seasoned professional or new to the industry, this guide will equip you with the insights necessary to choose the most suitable Hollow Board for your business.

When selecting a hollow board for your business needs, understanding the various types available in the market is crucial. Hollow boards are primarily categorized based on their material composition, thickness, and intended use. Common materials include polypropylene, polycarbonate, and recycled paper, each offering distinct strengths. For instance, polypropylene boards are lightweight yet durable, making them ideal for both indoor and outdoor applications, while polycarbonate boards provide superior impact resistance, perfect for more demanding environments.

Another essential factor to consider when choosing a hollow board is its thickness, which can affect durability and handling ease. Thicker boards offer more strength and longevity, ideal for packaging heavier items or outdoor signs exposed to the elements. Conversely, thinner boards may be more suitable for lightweight projects or temporary displays. Additionally, exploring options for customization—such as color, printing, and shape—can help align your choice with your business branding and specific functional requirements. Understanding these differences will position you to make an informed decision that best serves your organization's goals.

This chart illustrates the preference for different types of hollow boards among businesses based on a survey conducted. The data reflects the percentage of businesses that favor specific types of hollow boards for their operational needs.

When selecting the best hollow board for your business, it is essential to consider several key factors that can significantly impact your operational efficiency. First, assess the material quality. High-grade hollow boards are not only lightweight but also provide excellent durability, ensuring they can withstand various conditions while keeping costs manageable. Choosing a board made from high-impact polypropylene can lead to longer service life and reduced maintenance costs.

Another crucial aspect is the board's thickness and size. These dimensions will vary depending on your specific needs—be it for packaging, advertising, or display setups. Opting for customizable options allows businesses to cater to specific requirements, providing flexibility in various applications. Additionally, consider the environmental impact of the materials. Selecting eco-friendly hollow boards can enhance your brand image and appeal to socially conscious consumers.

Lastly, think about the supplier's reputation. A reliable supplier not only guarantees quality but also provides good customer service and support. Investing time in researching and comparing different suppliers will help you make an informed decision, ensuring that the hollow board you choose truly aligns with your business goals.

When selecting a hollow board for your business needs, evaluating its durability and weight capacity is crucial. Durability is often determined by the material used and the manufacturing process. High-quality hollow boards are typically made from robust materials such as polypropylene or polyethylene, which offer resistance to impact and environmental degradation. It’s important to check the manufacturer’s specifications regarding the board’s performance under stress; boards designed for heavy-duty applications should demonstrate minimal deformation when subjected to weight.

Equally essential is understanding the weight capacity of the hollow boards you are considering. This involves assessing both the maximum load the board can support and the distribution of that weight across its surface. Different applications may require varying levels of weight capacity—whether for packaging, storage, or display purposes. Conducting practical tests or reviewing user feedback can provide insights into how well the board performs under real-world conditions. Balancing durability with appropriate weight limits ensures that you choose a hollow board that meets your operational requirements effectively while minimizing the risk of damage or failure.

When choosing the best hollow board for your business needs, cost-effectiveness plays a crucial role. As brands face escalating business costs, finding the right balance between quality and price can be challenging yet essential for survival in a competitive market. Recent reports indicate that businesses emerging from the pandemic must focus on efficiency and quality to ensure sustainable growth, emphasizing that cutting costs without losing quality can ultimately lead to a decline in customer satisfaction and brand loyalty.

Tip 1: Identify your specific needs. Determine what features of the hollow board align with your operational goals. For example, if you're in the logistics sector, boards with superior durability may initially appear costlier but can save money long-term due to reduced replacements.

Tip 2: Conduct a cost-benefit analysis. Evaluate not just the initial purchase price, but also the lifecycle costs of the hollow boards you consider. A well-informed choice may involve paying a higher upfront cost for a product that offers enhanced performance and longer service life, ultimately minimizing future expenditures.

By keeping these tips in mind, you can navigate the complexities of price and quality, ensuring you make a sound investment for your business.

When it comes to maintaining and caring for your hollow boards, adopting best practices is essential to ensure longevity and optimal performance. Regular inspection is key; research from the Composite Panel Association indicates that properly maintained boards can last up to 25% longer than those that are neglected. Make it a habit to check for any signs of wear or damage, and address these issues promptly to avoid further degradation.

Another important tip is to keep your hollow boards clean. Dust, debris, and moisture can compromise the integrity of the material. Use a mild detergent and soft cloth to clean the surface regularly, as recommended by industry experts. Avoid abrasive materials, which can scratch and weaken the board. Reports suggest that a consistent cleaning routine can enhance the surface finish and prevent potential problems.

Lastly, it’s crucial to store your hollow boards in a controlled environment. Extreme temperatures and humidity can lead to warping or other structural issues. A climate-controlled area can help mitigate these risks; studies show that maintaining stable conditions can extend the lifespan of hollow boards significantly. By implementing these simple yet effective maintenance strategies, you can ensure that your hollow boards serve your business needs for years to come.

| Tip Number | Tip Description | Benefits | Maintenance Tip |

|---|---|---|---|

| 1 | Determine the right thickness for your needs | Increased durability and performance | Regularly inspect for wear and tear |

| 2 | Choose the right size for your projects | Optimal space management | Clean surfaces after each use |

| 3 | Consider the material type for your hollow board | Enhanced weight capacity and longevity | Store in a dry environment |

| 4 | Evaluate the cost vs. longevity | Better investment over time | Avoid exposure to extreme temperatures |

| 5 | Look for non-toxic and eco-friendly options | Safer for both your employees and the environment | Use gentle cleaners for maintenance |

| 6 | Check for customizable options | Tailored solutions for specific projects | Regularly update any custom features |

| 7 | Read reviews and ask for recommendations | Informed decisions based on real user experiences | Engage with users for best practices |