How to Choose the Right Plastic Cap for Your Packaging Needs

When it comes to packaging, the choice of a plastic cap plays a crucial role. The right plastic cap can enhance product safety, usability, and shelf appeal. Yet, many people overlook this important detail. Choosing a plastic cap requires careful consideration of various factors.

Different products demand different types of caps. For instance, the seal might need to be tighter for liquids to prevent leaks. The material of the plastic cap also matters. Not all plastics offer the same protection. Some may interact with the product inside, affecting quality. Such nuances often get lost in the decision-making process.

Moreover, the design of the cap can impact user experience. A cap that is difficult to open can frustrate consumers. Yet, finding the perfect balance is a challenge. The options are plentiful, but they can also lead to confusion. Reflecting on these elements can ultimately lead to a wiser choice in plastic caps for packaging needs.

Understanding Different Types of Plastic Caps Available for Packaging

When selecting the right plastic cap for packaging, understanding the types available is crucial. There are several common plastic cap styles, each serving different functions. For instance, screw caps are popular for their ease of use. Snap-on caps, on the other hand, offer quick access for consumers. According to a recent report by Smithers Pira, the global market for plastic closures is expected to reach $65 billion by 2025. This indicates a growing preference for efficient packaging solutions.

Caps vary in materials as well. Polypropylene (PP) and polyethylene (PE) are frequently used due to their durability and flexibility. Interestingly, the choice of materials can impact sustainability efforts. Many brands are now leaning towards recycled options to meet consumer demands. However, not all products can use recycled materials effectively, leading to potential compromises in quality.

**Tip:** Focus on the intended use of your product. Will the cap be resealable? Consider using a cap that provides a tight seal.

The size of the cap matters as well. It must fit the bottle or container properly to avoid leakage. A poorly fitting cap can result in wasted product and frustrated customers. Despite extensive options, some manufacturers still struggle with fitting the right cap to their product. This gap could hinder sales and lead to customer dissatisfaction.

**Tip:** Always sample caps with your packaging before finalizing your choice. Doing so can prevent costly mistakes.

Evaluating Materials: Choosing the Best Plastic for Your Cap

Choosing the right material for your plastic cap is crucial. It directly impacts product safety, shelf life, and consumer experience. Common materials include polyethylene, polypropylene, and PET. Each type has unique properties that make it suitable for different packaging needs. Polyethylene is flexible. It’s often used for food and personal care products. Polypropylene offers better resistance to heat and is used in medical and pharmaceutical packaging.

However, not all materials are perfect. Polyethylene can be less rigid, providing poor protection against external elements. Polypropylene, on the other hand, might be too stiff for some applications, making it difficult to open. In some situations, you may find yourself struggling to find the balance between durability and usability.

It’s essential to conduct tests and gather feedback. Sometimes, the choice might lean towards cost-effectiveness rather than performance. This could lead to unsatisfied customers down the line. Consider how the selected material interacts with the product inside. The goal is to ensure safety and functionality are not compromised.

Plastic Cap Material Evaluation

This bar chart shows the evaluation of various plastic materials commonly used for packaging caps, considering properties such as durability, cost-effectiveness, and recyclability.

Assessing Compatibility with Product and Packaging Design

Choosing the right plastic cap is more than just a matter of style. Compatibility with your product and packaging design is crucial. A misfit can lead to leaks or contamination. Research shows that 73% of packaging failures are due to poor design compatibility. Therefore, selecting caps that match your bottle's dimensions and material is essential.

Testing is key. Perform compatibility assessments to ensure the cap seals properly. Use materials that won't react adversely with your product. For instance, certain chemicals can degrade standard plastics, leading to product spoilage. The type of closure also affects user experience. A cap that’s hard to open might discourage customers.

Tips: Always analyze your target market's preferences. Is convenience a priority? Consider child-resistant closures if needed. And don’t overlook your branding. A well-designed cap should reflect your product's image. Regularly review and gather feedback after launch. Remember, the best choice may not be the most complex one, but rather the one that aligns perfectly with your product goals.

How to Choose the Right Plastic Cap for Your Packaging Needs

| Cap Type | Material | Compatibility with Product | Sealing Performance | Design Flexibility |

|---|---|---|---|---|

| Screw Cap | Polypropylene (PP) | Highly compatible with oils and creams | Excellent sealing | Customizable in various colors |

| Flip Top Cap | Polyethylene (PE) | Good for liquid products | Moderate sealing | Limited design options |

| Pump Cap | ABS Plastic | Ideal for lotions and soaps | High sealing capability | Varied heights and nozzle options |

| Child-Resistant Cap | Polyethylene (PE) | Suitable for hazardous materials | Secure sealing | Design limited by safety features |

| Dropper Cap | Glass & Rubber | Perfect for oils and tinctures | Good sealing, though not hermetic | Highly customizable designs |

Identifying Regulatory Requirements and Compliance Standards

Choosing the right plastic cap for your packaging involves understanding regulatory requirements and compliance standards. Different industries have unique guidelines. For food and beverage products, safety is paramount. Caps must meet FDA regulations. They should be made from food-grade materials. Always check for certifications.

Tips: Verify whether your cap material is recyclable. This can impact your product's marketability.

For pharmaceuticals, caps often need tamper-evident features. This ensures safety and builds consumer trust. Non-compliance can lead to severe penalties. It can also harm your reputation.

Tips: Keep track of any updates to regulations. Standards can change frequently. Attending industry seminars can help you stay informed.

Ultimately, consider your audience. Do they care about sustainability? Understand their values. This can guide your cap selection. Balancing compliance with consumer preferences is crucial.

Considerations for Cost, Functionality, and Aesthetics in Selection

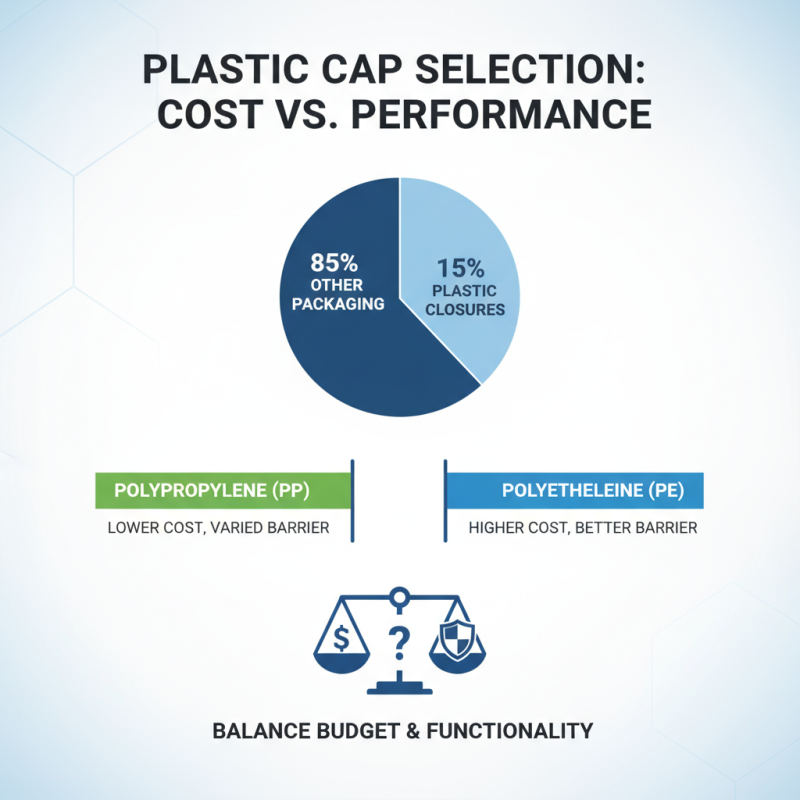

When selecting the right plastic cap for packaging, cost is a key factor. According to recent industry reports, plastic closures account for approximately 15% of total packaging costs. Understanding how different materials affect pricing is crucial. For example, polypropylene is often less expensive than polyethylene, but it might not provide the desired barrier properties. Finding a balance between budget and performance can be tricky.

Functionality should not be overlooked. The cap must ensure leak prevention and ease of use. About 30% of consumers report frustration with poorly designed caps. This highlights the need for thoughtful functionality. Consider the pourability and resealability aspects as well. Each element contributes to the overall user experience and can impact brand loyalty significantly.

Aesthetics also play a vital role in the selection process. Many brands fail to recognize that the visual appeal of packaging can drive consumer choices. A survey indicated that 65% of consumers are influenced by packaging design. Shapes, colors, and finishes can create a strong first impression. However, choosing an attractive cap should not compromise the cap's functional qualities. Balancing these aspects can be complex and requires careful consideration.

Related Posts

-

Top 10 Benefits of Using Plastic Caps for Packaging and Their Market Growth Insights

-

Unlocking Efficiency: The Advantages of Utilizing Plastic Caps in Packaging Solutions

-

Exploring Innovative Uses for Plastic Caps: From DIY Crafts to Sustainable Solutions

-

Understanding Injection Molding Tooling Processes and Their Industry Impact

-

Innovative Solutions for Polyvinyl Chloride Applications in Various Industries

-

2025 Top PVC Material Innovations for Sustainable Construction and Design