Understanding the Dip Molding Process for Plastic Caps & Custom Plastic Products

When it comes to manufacturing durable, flexible, and cost-efficient plastic caps, dip molding is one of the most reliable and versatile methods available. At Carlisle Plastics, we’ve perfected this process over decades to produce high-quality plastisol caps tailored to the unique needs of industries across North America and beyond.

Whether you’re protecting threads, sealing tubing, color-coding equipment, or finishing off exposed ends, our custom plastic caps are engineered for performance—and it all starts with dip molding.

What Is Dip Molding?

What Is Dip Molding?

Dip molding is a manufacturing process where a heated mold is dipped into liquid plastisol—a suspension of PVC particles in a plasticizer. Once the mold is submerged, a layer of plastisol clings to its surface. The coated mold is then heated again to cure the plastisol, forming a tough yet flexible plastic layer. After cooling, the finished cap is removed from the mold.

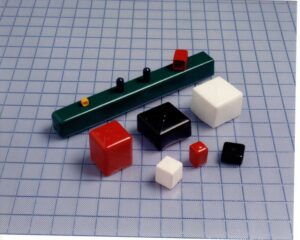

This method is especially effective for producing plastic caps, grips, plugs, and protective coatings in a wide range of shapes, colors, thicknesses, and finishes.

Why Use Plastisol?

Plastisol is the material of choice for dip molding due to its unique combination of flexibility, strength, and resistance to environmental conditions. Once cured, plastisol offers:

- Excellent chemical resistance

- Weatherproof durability, even in extreme temperatures

- High elasticity for snug, secure fits

- Custom color matching and texture options

These properties make plastisol the ideal material manufacturing plastic products that need to withstand mechanical stress, UV exposure, or regular handling.

Step-by-Step: How Carlisle Plastics Makes Custom Plastic Caps

At Carlisle Plastics Company, every plastic cap we produce is made to order. Here’s how the dip molding process works in our facility:

- Tooling the Mold: The first step is creating the molds that define the shape and size of the plastic cap. We design and manufacture our own metal tooling in-house to ensure precision and cost efficiency for both standard and custom cap profiles.

- Heating the Mold: The metal molds are heated to a controlled high temperature. This temperature allows the plastisol to adhere and partially gel on contact.

- Dipping the Mold: The heated mold is dipped into a tank of liquid plastisol. The duration of the dip (along with the temperature) controls the wall thickness of the plastic cap—the longer the dip, the thicker the coating.

- Curing the Plastisol: Once removed from the plastisol tank, the coated mold is transferred to a curing oven. There, it is held at high heat to fully fuse the plastisol into a strong, flexible plastic.

- Cooling and Removal: After curing, the molded parts are cooled, and the plastic is now set. The finished cap is then stripped from the mold, inspected, and packed for delivery.

Benefits of Dip Molding Over Other Methods

Benefits of Dip Molding Over Other Methods

Dip molding offers significant advantages over other cap manufacturing techniques such as injection molding or extrusion:

- Lower Tooling Costs: Since dip molding requires less upfront investment—the tooling required is ideal for short runs or specialty sizes.

- Design Flexibility: From rounded tips to flanged edges, varying wall thicknesses to textured finishes, the process allows for endless customizations.

- No Parting Lines: Dip-molded parts are seamless, which improves appearance and performance in sealing and protective applications.

- Cost Efficiency: Lower tooling costs, minimal material waste, and faster setup times contribute to a more economical production process.

Applications for Plastisol Dip-Molded Plastic Caps

Our plastic caps are used across a wide range of industries for protective, aesthetic, and functional purposes. Common applications include:

- Thread protection for screws, bolts, and rods

- Masking caps for painting, plating, or powder coating

- Grip handles for tools and machinery

- Moisture and dust barriers for pipes and tubes

- Color coding for inventory or safety marking

- Packaging end caps to prevent transit damage

From heavy-duty equipment to medical devices, our dip-molded caps meet the specific needs of clients across manufacturing, automotive, electronics, and consumer goods sectors.

Customization Is Our Specialty

At Carlisle Plastics Company, every plastic cap we produce is made to meet your exact requirements. We offer:

- Custom diameters, depths, and shapes

- Color matching and surface textures

- Flexible durometers (soft to semi-rigid)

- Special formulations for UV, flame, or chemical resistance

Need a prototype? Our in-house tooling shop can create custom molds quickly and affordably, making us a preferred partner for product engineers and procurement specialists looking for a dependable solution.

Why Choose Carlisle Plastics Company?

Why Choose Carlisle Plastics Company?

With over 60 years of experience and a commitment to American-made quality, Carlisle Plastics Company is a trusted name in dip molding. We’ve built long-standing partnerships by delivering consistent results, responsive service, and tailored solutions for every project.

When you need plastic products made with precision, durability, and fast turnaround—our team is ready to help.

Let’s Build Something That Fits

Looking for custom plastic caps made with dip molding? Let’s talk. Whether you have a technical drawing or just a product in hand, we’ll work with you to develop the perfect fit for your application.

What Is Dip Molding?

What Is Dip Molding?

Why Choose Carlisle Plastics Company?

Why Choose Carlisle Plastics Company?