How to Choose the Right PVC Film for Your Packaging Needs

In today's competitive packaging landscape, selecting the right PVC film is crucial for ensuring product integrity and brand visibility. The global PVC film market was valued at approximately $9.4 billion in 2021, with projections indicating a growth rate of 4.5% annually through 2028. This upward trend emphasizes the significance of choosing high-quality materials that meet specific application demands. As noted by packaging industry expert Dr. Emily Turner, “The choice of PVC film not only affects product protection but also influences the overall consumer experience.”

Understanding the various properties of PVC film—such as barrier performance, flexibility, and clarity—can significantly impact your packaging strategy. With the increasing emphasis on sustainable practices, it is essential to consider not only the functionality of PVC films but also their environmental implications. Properly assessing your packaging needs and the characteristics of available PVC films will enable businesses to improve supply chain efficiency, enhance branding efforts, and reduce waste. Navigating this landscape requires keen insight into both market trends and technological advancements, making informed decisions paramount.

Understanding PVC Film: Types and Their Uses in Packaging

PVC film is a versatile material commonly used in packaging due to its excellent properties, which vary depending on the specific type of film utilized. The three main types of PVC film—rigid, flexible, and shrink—each serve distinct purposes. Rigid PVC film is ideal for creating sturdy packaging solutions, such as clamshells and trays, which require structural integrity to protect the contents. This type of film is often employed in sectors like food packaging, where visibility and durability are paramount.

Flexible PVC film, on the other hand, offers superior stretchability and can easily conform to various shapes, making it suitable for wrapping products like produce and baked goods. Its flexibility allows for easy handling and sealing, ensuring that products remain fresh and protected during transportation.

Lastly, shrink PVC film is specifically designed for heat-shrinking applications, allowing it to tightly wrap around products. This type is widely used for bundling multiple items together or providing tamper-proof seals, enhancing security and product presentation. Understanding these types of PVC film and their respective applications is crucial for selecting the right packaging solution that meets specific business needs.

Key Factors to Consider When Choosing PVC Film for Packaging

When selecting the right PVC film for packaging, it is crucial to consider several key factors to ensure that the film meets your specific requirements. One of the primary considerations is the thickness of the PVC film. Thicker films generally provide more durability and protection, making them suitable for heavy or fragile items. Conversely, thinner films may be ideal for lighter products and those requiring more flexibility. Assessing the thickness ensures that your packaging can withstand transportation and storage conditions without compromising the integrity of the items inside.

Another important factor to consider is the clarity and gloss level of the PVC film. High clarity films are essential for products that must showcase their appearance, such as food items or cosmetics. The gloss level can significantly affect the overall presentation; a high-gloss finish may enhance the visual appeal, while a matte finish may be preferred for a more subtle look. Additionally, evaluating the sealability and barrier properties of the film is vital. Good sealability ensures that the packaging remains intact during shipping, while effective barrier properties protect the contents from moisture, gases, and other contaminants, preserving quality and extending shelf life. By carefully considering these factors, you can select a PVC film that meets both functional and aesthetic needs for your packaging.

Comparison of PVC Film Thickness for Packaging Needs

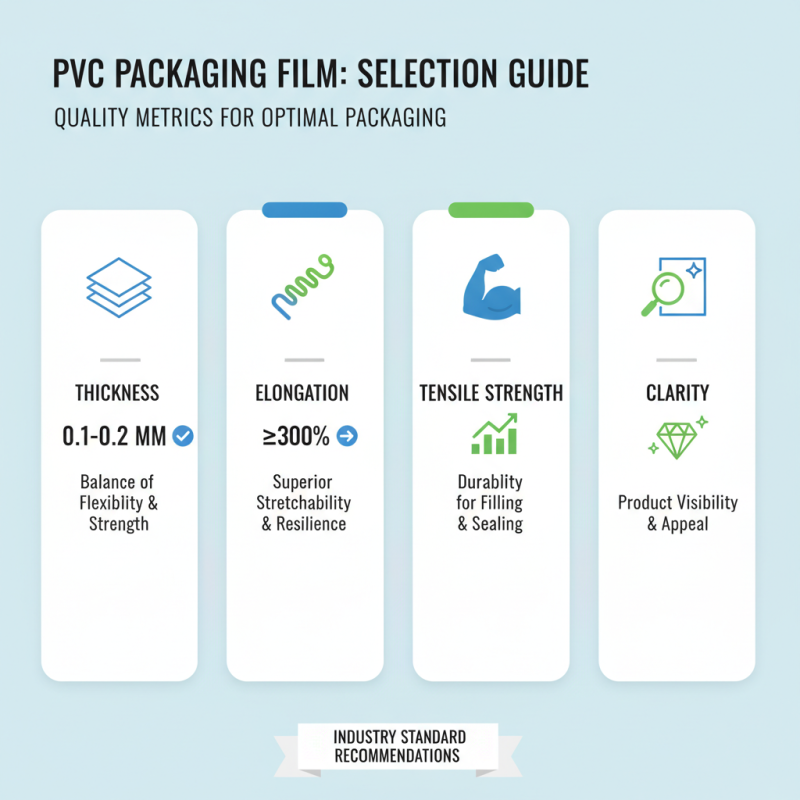

Evaluating Quality: How to Assess PVC Film Specifications

When selecting the right PVC film for your packaging needs, the quality of the film is paramount. To effectively evaluate PVC film specifications, start by examining factors such as thickness, elongation, tensile strength, and clarity. According to industry reports, films with a thickness range of 0.1 to 0.2 mm are generally considered optimal for most applications, providing a balance of flexibility and strength. Additionally, look for films with at least 300% elongation, as this indicates superior stretchability, making the film more resilient during filling and sealing processes.

Tips: Always check the manufacturer’s technical datasheets, as they often provide detailed information on the film's performance under various conditions. Look for certifications or compliance with industry standards, as these can serve as indicators of quality.

Another important specification to consider is the film's barrier properties. High-quality PVC films should exhibit low permeability for oxygen and moisture, which is crucial for preserving the freshness of perishable goods. Recent market analyses highlight that films with enhanced barrier properties can improve the shelf life of packaged products by up to 30%. Therefore, investing in PVC films with superior barrier features can lead to significant long-term benefits in product quality and customer satisfaction.

Tips: Conduct comparative testing of different samples in real-world conditions to see how they perform with your specific products. This hands-on approach can reveal critical insights into which film best meets your packaging objectives.

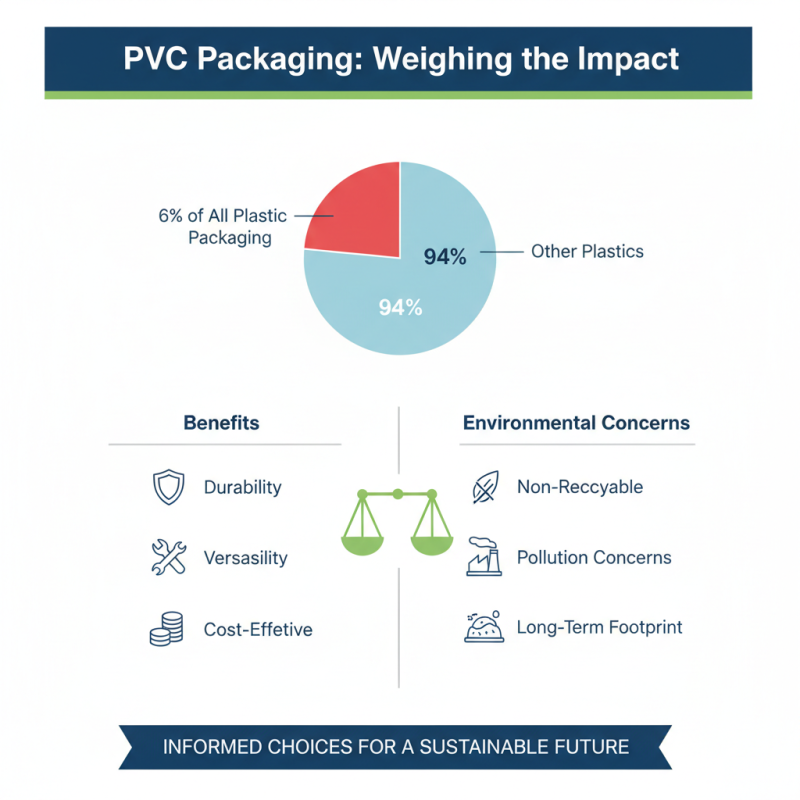

Environmental Impact: Sustainable Choices in PVC Packaging

The environmental impact of packaging materials has become a critical concern in today’s economy, and PVC (polyvinyl chloride) film is no exception. While PVC is prized for its durability, versatility, and cost-effectiveness, it also faces scrutiny regarding its sustainability profile. According to a report by the Global Packaging Alliance, PVC packaging accounts for approximately 6% of all plastic packaging, and its use continues to raise questions about its long-term environmental effects. To make informed choices, businesses must weigh the benefits against the potential environmental footprint of PVC.

To address these concerns, many manufacturers are exploring alternative solutions, such as bio-based PVC and recyclable film variants. Research from the European Plastic Converters indicates that transitioning to reusable and recyclable materials can reduce the carbon footprint by up to 30% compared to standard PVC products. Furthermore, the incorporation of recycled materials into the production of PVC film not only lessens environmental impact but also helps to create a circular economy. By choosing PVC films certified for sustainability or those produced with lower environmental impact processes, companies can contribute positively to ecological preservation while still meeting their packaging needs.

Cost vs. Performance: Balancing Budget and Quality in PVC Film

When selecting the appropriate PVC film for packaging applications, one of the most critical considerations is the balance between cost and performance. According to a report by the Flexible Packaging Association, the demand for PVC films in packaging has grown significantly, with the global market expected to reach approximately $31 billion by 2025. This growth underscores the need for businesses to carefully analyze the specifications and performance characteristics of various PVC films while simultaneously managing their budgets.

In terms of cost efficiency, PVC films typically offer low material costs, making them a popular choice for budget-conscious businesses. However, it is crucial to note that opting for the cheapest option can lead to increased costs in the long run, especially if the film fails to perform adequately. A study published by Smithers Pira highlights that high-quality PVC films can enhance product protection and shelf life, which ultimately reduces waste and improves overall profitability. Companies must thus weigh the immediate savings against the potential for higher operational costs due to inferior film performance.

Moreover, investing in higher-quality PVC film can contribute to better product presentation and consumer satisfaction, which are vital for brand loyalty. According to a survey conducted by The Packaging Association, 67% of consumers reported that packaging quality influences their purchasing decisions. This indicates that while a lower upfront cost is appealing, the performance and aesthetic impact of quality PVC films can lead to greater long-term benefits, reinforcing the need to find a balance that fits both budgetary constraints and performance requirements.

Related Posts

-

Exploring the Versatility and Applications of PVC Film in Modern Industries

-

7 Amazing Benefits of Using PVC Material in Modern Manufacturing

-

Exploring the Versatility of PVC Material: Applications, Benefits, and Environmental Impact

-

10 Best PVC Material Products for Durable Home and Garden Solutions

-

What is the Role of Plastic Sheets in Modern Industries

-

Exploring the Versatility of PVC Sheets: Innovative Applications You Didn't Know About