10 Essential Tips for Choosing the Right Plastic Material for Your Project?

When embarking on a new project, choosing the right plastic material can be daunting. Experts in the industry highlight the complexity of this decision. Dr. Emily Carter, a leading materials scientist, once stated, "The right plastic can make or break your project." Her insight underscores the significance of understanding the properties and applications of various plastics.

Selecting plastic material directly impacts both functionality and cost. Each type of plastic has unique characteristics. For example, PVC is durable but harder to recycle, while PLA is biodegradable but may not be as sturdy. Mistakes can lead to project delays or increased expenses. Evaluating multiple options is essential.

It’s easy to overlook the importance of compatibility between your project's needs and the chosen plastic material. Not every plastic suits every application. A thoughtful approach is necessary. Consider weight, strength, and environmental impact. Engage with experts and conduct thorough research. These steps can guide you to make informed choices that align with your goals.

Understanding Different Types of Plastic Materials and Their Properties

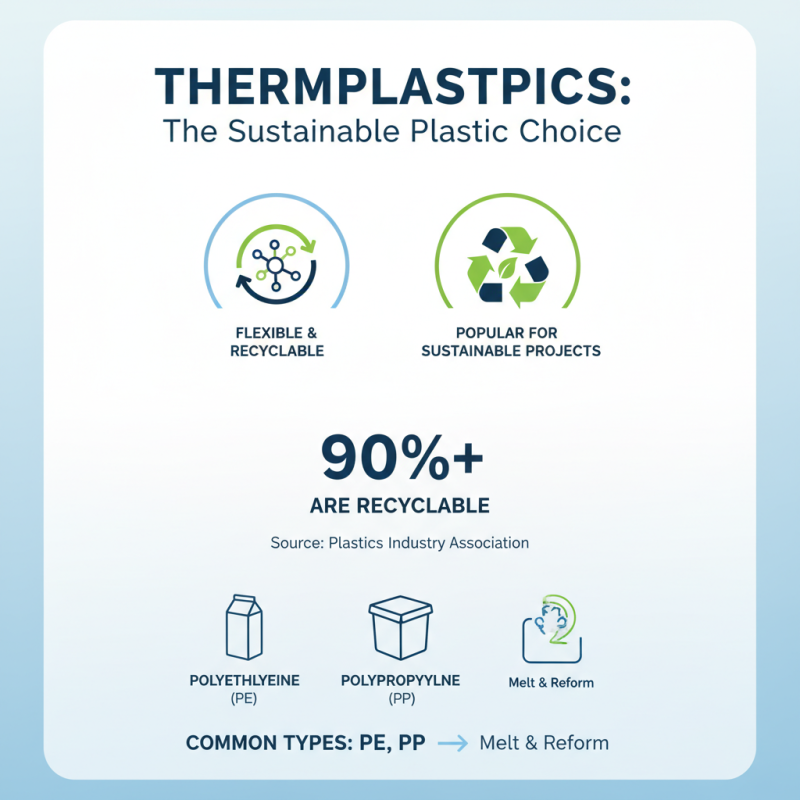

When choosing the right plastic material, understanding the properties of various types is crucial. Thermoplastics, such as polyethylene and polypropylene, offer flexibility and recyclability. According to the Plastics Industry Association, over 90% of thermoplastics are recyclable. This makes them a popular choice for sustainable projects.

On the other hand, thermosetting plastics, like epoxy and phenolic, provide durability and heat resistance. However, they cannot be remolded once set. This can be a limitation for projects requiring adaptability. A report from the American Chemistry Council highlights that thermosets account for about 25% of the global plastic market.

Consider the environment when selecting materials. Not all plastics are biodegradable. The need for sustainable options is growing. In fact, a study by the Ellen MacArthur Foundation emphasizes that only 14% of plastic packaging is recycled globally. This raises questions on the long-term impact of plastic use. Developers must reflect on their choices to minimize ecological footprints.

Assessing Project Requirements: Functionality, Durability, and Aesthetics

Choosing the right plastic material involves understanding functionality, durability, and aesthetics. Each project has unique requirements, and these factors guide your selection.

When considering functionality, assess how the material will perform in its intended use. For example, polypropylene offers excellent resistance to fatigue, making it ideal for reusable containers. However, its color options might be limited. Evaluating industry reports shows that around 30% of project failures stem from choosing the wrong material based on function, revealing the importance of this step.

Durability is equally essential. Different plastics exhibit varying resistance to environmental stressors. For example, polycarbonate is renowned for its impact resistance but can yellow over time. A study by the American Society for Testing and Materials highlights that materials' lifespan can drastically affect overall project costs. Opting for higher durability can prevent frequent replacements and reduce waste.

Aesthetics also play a role. The visual appeal can impact user experience. Not all plastics can be easily colored or finished. A material may have desirable mechanical properties but lack the necessary aesthetic qualities, which can lead to dissatisfaction. Balancing these aspects requires careful thought and sometimes compromise, as the most functional materials might not always align with design visions.

Material Selection Criteria for Plastic Projects

Evaluating Cost-Effectiveness: Budgeting for Plastic Material Selection

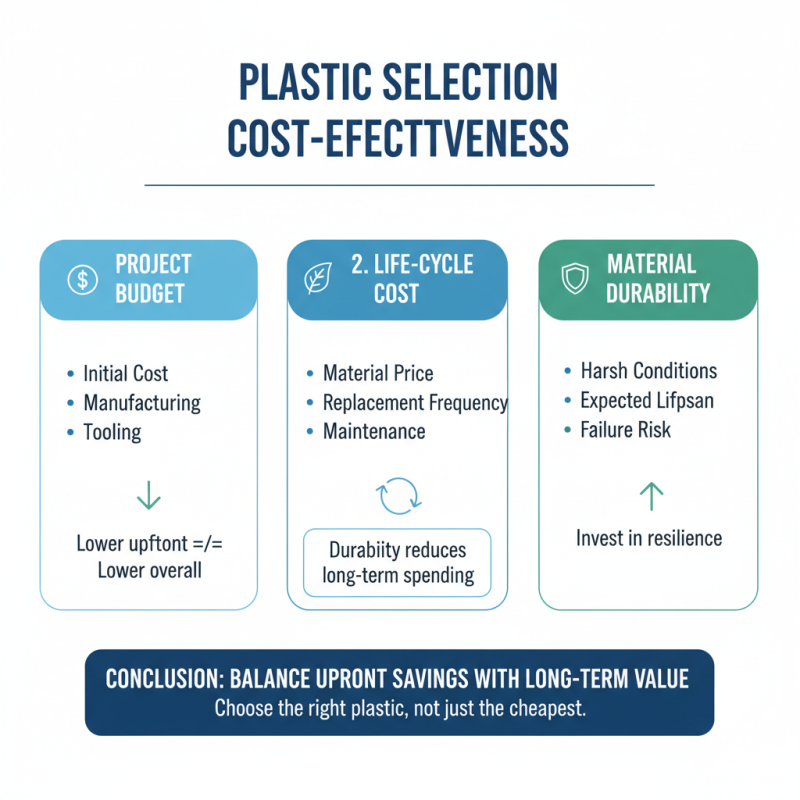

When evaluating cost-effectiveness for plastic material selection, it’s essential to analyze your project's budget. Consider the life cycle cost of materials. Cheap options might save money upfront but can lead to higher replacement costs. Think about durability. Does the material need to withstand harsh conditions? If a cheaper plastic fails early, you might end up paying more in the long run.

One tip is to assess the material's performance characteristics. For example, some plastics offer UV resistance, reducing fading and wear. Choosing a higher-quality plastic can also save costs on maintenance and repairs. Pay attention to procurement options, too. Bulk buying can lower individual prices, but ensure you have storage and handling plans.

Don’t forget about hidden costs. Shipping fees can add up if the material is heavy or bulky. Also, factor in processing times. Delays can lead to stalled projects and higher labor costs. Keep the total project budget in mind while making your choices. Consider whether the higher upfront investment will pay off over time. Reflecting on these aspects will help guide your decisions effectively.

Environmental Considerations: Sustainability and Recycling Options

When choosing plastic materials, environmental considerations are crucial. Sustainable practices are reshaping the industry. A study by the Plastics Industry Association found that around 40% of plastics produced are now made from recycled sources. This shift not only reduces waste but also lessens the dependency on fossil fuels.

Choosing recyclable materials can significantly impact the environment. For instance, polycarbonate, while durable, has a lower recycling rate of 20% compared to PET, which boasts a recycling rate of 57%. Awareness is growing, yet many industries lag in adopting green materials. The challenge lies in balancing performance and sustainability.

It's essential to recognize the limitations too. Not all recyclable plastics have accessible recycling systems. Some end up in landfills, even when labeled recyclable. The circular economy is still developing. As consumers, we must push for better systems and choices that prioritize sustainability. Industry reports emphasize that only 9% of plastic is ever recycled globally. This stark reality calls for more responsible choices now.

10 Essential Tips for Choosing the Right Plastic Material for Your Project - Environmental Considerations: Sustainability and Recycling Options

| Tip Number | Tip Description | Material Examples | Recyclability | Environmental Impact |

|---|---|---|---|---|

| 1 | Consider applications and requirements. | PP, PET | Yes | Low impact when recycled properly. |

| 2 | Evaluate mechanical properties. | ABS, Nylon | Partially | Moderate impact; some grades are recyclable. |

| 3 | Check for environmental certifications. | Bioplastics | Yes | Low impact; made from renewable resources. |

| 4 | Consider lifecycle analyses. | PETG, PLA | Yes | Requires attention to disposal methods. |

| 5 | Assess heat resistance. | PVC, HDPE | Yes | Moderate, especially HDPE. |

| 6 | Think about the impact of chemical exposure. | Polycarbonate, PMMA | Limited | Potentially high if not managed. |

| 7 | Evaluate aesthetics and finish. | Acrylic, PS | Yes | Low when disposed of responsibly. |

| 8 | Consider the cost and availability. | PP, PS | Yes | Generally low impact. |

| 9 | Account for UV stability. | PVC, PET | Yes | Minimal; maintenance reduces waste. |

| 10 | Research the latest innovations. | Recycled plastics, composites | Yes | Potentially low, promoting a circular economy. |

Consulting with Experts: Getting Professional Advice on Material Choices

When it comes to selecting plastic materials for any project, consulting with experts is crucial. Professionals can provide insights that might not be apparent to newcomers. For instance, according to a report by the Plastics Industry Association, 70% of successful projects involve expert consultation. They can guide you on the strengths and weaknesses of various materials.

Experts analyze your specific needs. Their knowledge can save time and resources. For instance, using the wrong plastic can lead to product failure. A recent survey showed that 30% of projects failed due to improper material selection. Therefore, engaging with professionals ensures that your choice aligns with both the project's goals and budget constraints.

Material selection requires careful consideration. Each type of plastic offers unique characteristics. Some are stronger, while others are more flexible. This complexity often leads to missteps. Relying solely on online resources may not provide the depth required. A report by Allied Market Research indicated that 40% of manufacturers prefer consulting experts to enhance material efficiency and sustainability. Seeking professional advice ultimately reduces the chances of costly errors in the long run.

Related Posts

-

Best Plastic Materials for Sustainable Solutions?

-

How to Optimize Your Production Process with Poly Plastic Solutions

-

7 Essential Tips for Sourcing Plastic Parts Globally

-

Unlocking Innovation: The Future of Design for Injection Molding in 2025

-

How to Choose the Best Injection Molded Parts for Your Project Needs

-

Top Uses of Poly Plastic in Everyday Life and Its Environmental Impact