10 Essential Tips for Working with Polyvinyl Chloride PVC

Polyvinyl chloride, commonly known as PVC, plays a crucial role in various industries. As Dr. Alice Thompson, a leading expert in polymer science, states, "Understanding the nuances of polyvinyl chloride is essential for successful applications." This versatile material is used in construction, healthcare, and consumer products, among others.

Working with polyvinyl chloride requires careful consideration of its properties. For instance, it can be rigid or flexible, depending on the additives used. Many people overlook these details, leading to issues in their projects. Recognizing the specific characteristics of PVC helps to avoid common pitfalls.

There is a strong need for awareness in the industry. Many professionals focus on cost rather than quality, which can result in long-term consequences. By acknowledging the importance of proper handling and processing of polyvinyl chloride, individuals can enhance their outcomes and ensure better longevity of their products.

Understanding the Basics of Polyvinyl Chloride (PVC) Material Properties

Polyvinyl Chloride (PVC) is a versatile material widely used in construction and various industries. Its key properties include durability and chemical resistance. In fact, PVC has a tensile strength ranging from 40 MPa to 70 MPa, according to industry reports. This makes it suitable for pipes, flooring, and more. However, its rigidity can sometimes be a drawback. Flexible PVC can be challenging to work with, especially when it comes to bending and shaping.

Thermal stability is another important aspect of PVC. The material can withstand temperatures up to 60°C before it starts to degrade. However, improper handling during high-temperature applications may lead to bending. Additionally, while PVC is resistant to many chemicals, it is crucial to avoid prolonged contact with strong solvents like acetone. These factors highlight the importance of understanding PVC's limitations before starting a project.

The environmental considerations surrounding PVC also merit attention. Although it is durable, its production releases harmful emissions. According to a 2022 environmental report, PVC production can result in significant carbon footprints. Recycling rates for PVC remain low, with only about 10% being processed properly. This raises questions about sustainability. Careful thought and planning are essential when choosing PVC for any application.

Key Applications of PVC in Construction and Manufacturing Industries

Polyvinyl Chloride (PVC) plays a crucial role in construction and manufacturing. In the construction sector, PVC is often used for pipes, siding, and window frames. According to a 2021 report by the American Chemistry Council, PVC is the leading plastic in building materials, accounting for about 30% of the total volume of plastic used in the sector.

One reason for this popularity is PVC's durability and resistance to corrosion. These properties make it an ideal choice for plumbing systems. In fact, over 50% of new constructions opt for PVC piping due to its reliability and cost-effectiveness. However, the production of PVC can be controversial. Environmental concerns arise from its lifecycle, and this has led to calls for better recycling practices.

In manufacturing, PVC is utilized in a variety of products. It is used in flooring, roofing membranes, and even in packaging. The global PVC market was valued at approximately $74 billion in 2020 and is expected to grow. Yet, the focus should not solely be on growth. Companies must address the environmental impact of PVC production and disposal. Balancing innovation with sustainability will be essential in future applications.

10 Essential Tips for Working with Polyvinyl Chloride PVC - Key Applications of PVC in Construction and Manufacturing Industries

| Application Area | Description | Advantages | Common Formulations |

|---|---|---|---|

| Pipes and Fittings | Used for plumbing and drainage systems. | Corrosion resistance, lightweight, low cost. | Schedule 40, Schedule 80 |

| Window Frames | Used in energy-efficient windows. | Energy efficiency, durability, low maintenance. | Unplasticized PVC (uPVC) |

| Roofing Membranes | Used in commercial roofing for waterproofing. | Weather resistance, longevity, energy efficiency. | Flexible PVC |

| Flooring | Used in residential and commercial flooring systems. | Durability, variety of designs, easy maintenance. | Vinyl Composition Tile (VCT), Luxury Vinyl Tile (LVT) |

| Insulation | Used for electrical and thermal insulation. | Excellent insulation properties, fire resistance. | Foamed PVC |

| Packaging | Used for producing plastic films and containers. | Lightweight, flexibility, moisture resistance. | PVC Films |

Safety Guidelines for Handling and Processing PVC Materials

When working with polyvinyl chloride (PVC), safety is crucial. Proper handling can prevent accidents and ensure a smooth workflow. Always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and masks. These items protect you from potential chemical exposure during cutting or heating processes. Use tools designed for PVC; dull or incorrect tools can create unnecessary risks.

Be mindful of ventilation when processing PVC. Fumes may be released during cutting or melting. Working in an open area or using exhaust fans can improve air quality. Monitor the temperature closely while working with PVC. Overheating can lead to harmful emissions. If you smell something off, take breaks and ventilate the area.

Regularly review your working practices. Are you following safety guidelines consistently? Reflect on your methods and adjust as needed. Mistakes can happen, but learning from them is vital. Keep a notebook for safety observations. This practice can help identify repetitive issues. Always prioritize safety to create a healthy working environment.

Environmental Considerations: Recycling and Sustainability of PVC

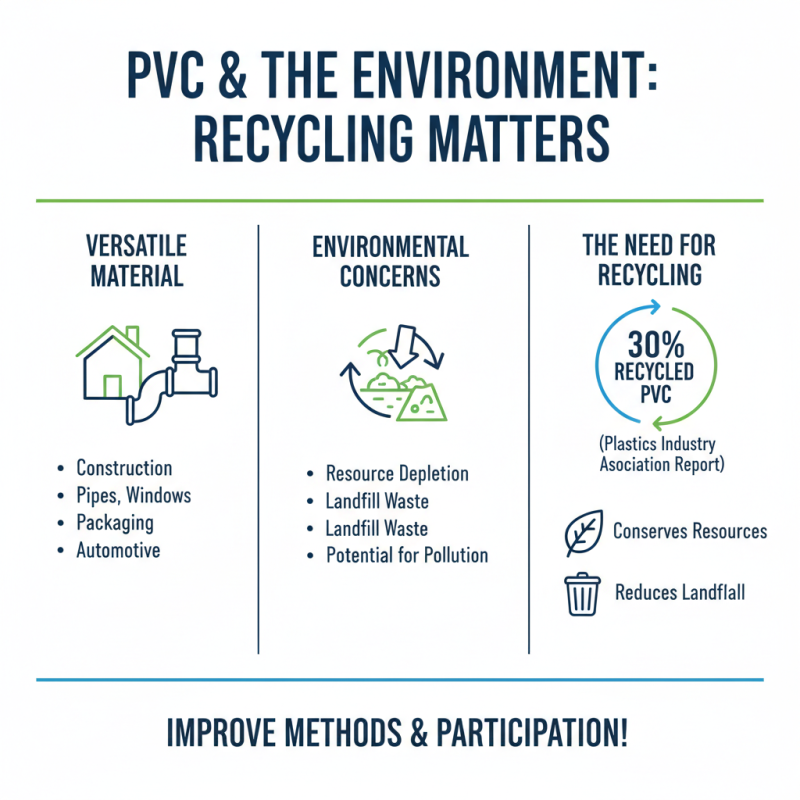

Polyvinyl Chloride (PVC) is widely used in construction and various products due to its versatility. However, its environmental impact raises significant concerns. According to a report by the Plastics Industry Association, about 30% of all PVC produced is recycled, which is a modest figure. This highlights the need for improved recycling methods and consumer participation. Recycling PVC can reduce landfill waste and conserve natural resources.

Despite its potential, the recycling process of PVC faces challenges. Contaminants can often affect the quality of recycled materials. A study from the European Commission noted that the recycling rate could increase significantly with better sorting technologies and public awareness. Encouraging responsible disposal practices is essential. Educating manufacturers and consumers can lead to greater recycling rates, minimizing the environmental footprint of PVC.

Sustainability in PVC production is another crucial aspect. Innovations in production methods can lower greenhouse gas emissions. Reports indicate that using bio-based additives in PVC can enhance its sustainability. However, many traditional PVC products still rely on non-renewable resources. This contradiction urges stakeholders to seek solutions. The path forward is not straightforward. Challenges remain, but progress is possible through collaboration and commitment to eco-friendly practices.

Best Practices for Joining and Fabricating PVC Components in Projects

When working with polyvinyl chloride (PVC), understanding best practices for joining and fabricating components is crucial. According to the Plastic Pipe and Fittings Association (PPFA), PVC is widely used in construction due to its durability and cost-effectiveness. However, improper joining techniques can lead to failures and increased project costs. Always ensure the surfaces to be joined are clean and free from contaminants. Adhesives should be applied evenly, using a brush or applicator. This attention to detail is essential for ensuring a successful bond.

Temperature and humidity can affect PVC's behavior. The American Society for Testing and Materials (ASTM) report indicates that PVC can become brittle in cold conditions. Using heat guns can help during fabrication, but overheating should be avoided. If you notice bubbling or discoloration, it's a sign of excessive heat. In addition, alignment during the joining process is vital. Misalignment can cause stress points, leading to failure in critical areas.

Precision tools can assist in achieving better cuts and joints. However, many DIYers overlook this aspect. Proper cutting tools create cleaner edges, which helps in achieving tighter seals. It’s also important to consider the environment where the PVC will be used. UV exposure can degrade PVC, so protective measures might be necessary if it will be outside. Reflecting on these details can enhance the overall quality of your project.

10 Essential Tips for Working with Polyvinyl Chloride (PVC)

This chart presents the importance level of various best practices for working with PVC, rated on a scale from 1 to 10. Higher values indicate greater significance in the context of joining and fabricating PVC components in projects.

Related Posts

-

Innovative Solutions for Polyvinyl Chloride Applications in Various Industries

-

7 Amazing Benefits of Using PVC Material in Modern Manufacturing

-

Unlocking the Advantages of Polyvinyl Chloride for Global Supply Chain Efficiency

-

Understanding the Versatility of PVC Material in Everyday Applications

-

10 Best PVC Material Products for Durable Home and Garden Solutions

-

Top Uses of Poly Plastic in Everyday Life and Its Environmental Impact