Exploring the Future of Injection Molding at the 138th Canton Fair 2025: Industry Insights and Growth Projections

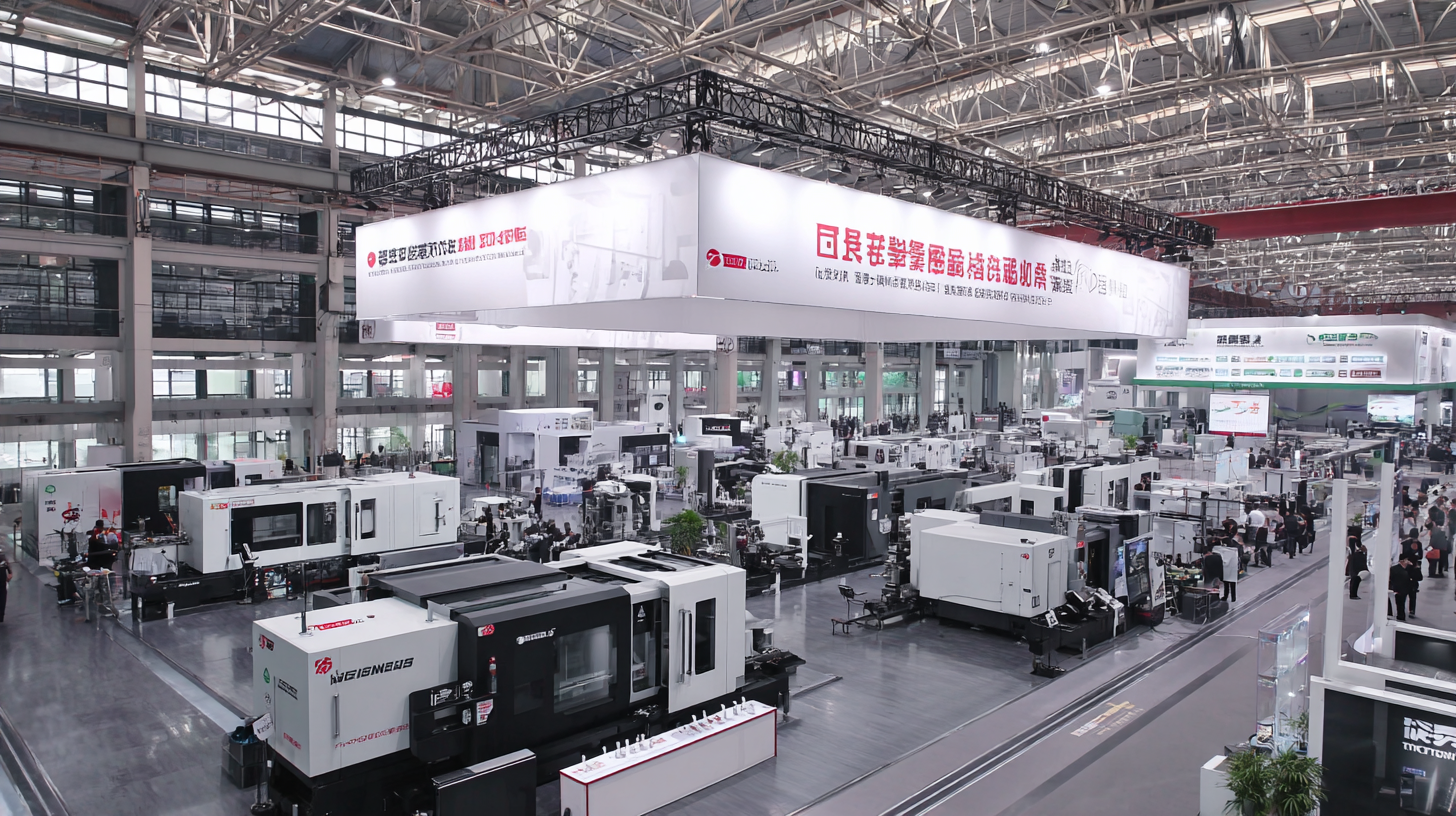

The 138th Canton Fair in 2025 stands as a pivotal event for the injection molding industry, showcasing the latest advancements and fostering connections among global stakeholders.

As the market for injection molding continues to expand, projected growth rates indicate a surge from USD 265 billion in 2020 to an estimated USD 380 billion by 2026, according to industry analysis reports. This rapid increase is driven by the rising demand for lightweight and durable materials across sectors such as automotive, consumer goods, and medical devices. Additionally, the adoption of smart manufacturing and automation technologies is revolutionizing production efficiency and precision in injection molding processes. At the Canton Fair, attendees will engage with industry experts and gain key insights into innovations that are shaping the future of injection molding, making it an essential platform for manufacturers and investors alike.

Future Trends in Injection Molding: Technology Innovations and Applications

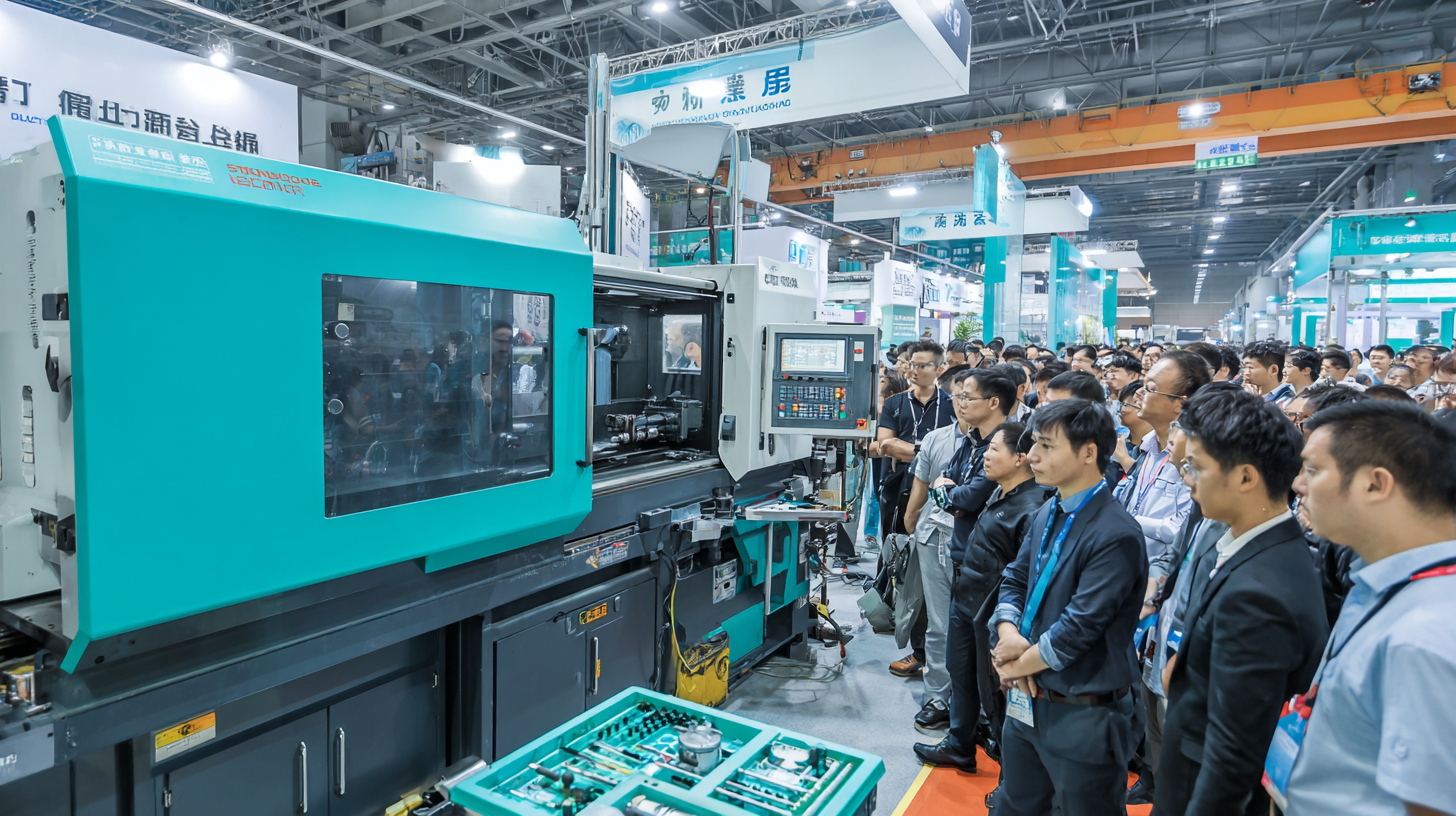

The future of injection molding is poised for transformative growth, driven by technological innovations and the increasing shift towards smart manufacturing. As traditional factories undergo digital transformations, the incorporation of advanced technologies such as machine vision and IoT is becoming essential for enhancing operational efficiency. This trend is particularly relevant for the injection molding sector, where automation and precision are crucial for producing high-quality components.

Emerging materials and techniques are also reshaping the landscape of injection molding. Innovations such as liquid silicone rubber (LSR) and liquid injection molding (LIM) are gaining traction, with market forecasts indicating significant growth potential in the coming years. These advancements not only enhance the versatility of applications across industries, from automotive to consumer goods, but also align with the broader push towards sustainability and lightweight materials. The integration of AI in manufacturing processes further complements these developments, enabling real-time optimization and improved decision-making capabilities, ultimately redefining the future of injection molding.

Market Growth Projections for Injection Molding Industry by 2025

The injection molding industry is poised for significant growth by 2025, driven by advancements in technology and increasing demand for precision-engineered components across various sectors. Market research indicates a compound annual growth rate (CAGR) that reflects the industry's resilience and adaptability in the face of evolving consumer needs and sustainability standards. Key players in the market are focusing on innovating their processes to enhance efficiency and reduce waste, aligning their operations with global environmental goals.

**Tip:** Companies should consider investing in automation and smart manufacturing technologies to improve production efficiency and reduce downtime. These investments can lead to significant cost savings and enhance product quality, positioning businesses to meet the rising competition.

In addition, the push for sustainable materials is reshaping the landscape of injection molding. Biodegradable plastics and recycled materials are gaining traction, prompting manufacturers to adapt their methodologies. This shift not only caters to eco-conscious consumers but also complies with stricter regulatory frameworks aimed at reducing plastic waste.

**Tip:** Staying informed about sustainable material options and integrating them into production processes can not only help companies meet regulatory demands but also appeal to a growing market segment that prioritizes environmental responsibility.

Market Growth Projections for the Injection Molding Industry by 2025

Impact of Sustainability Practices on Injection Molding Techniques

The impact of sustainability practices on injection molding techniques is becoming increasingly significant as the industry evolves. As reported by the Plastics Industry Association, about 70% of companies are now prioritizing sustainability in their production processes. This shift is driven by a growing consumer demand for eco-friendly products and regulatory pressures aimed at reducing plastic waste. By adopting practices such as using recyclable materials and implementing energy-efficient machinery, companies can significantly reduce their carbon footprint.

Moreover, advancements in technology are enhancing the sustainability of injection molding. According to a study by Research and Markets, the global market for biodegradable plastics in injection molding is expected to reach $4.2 billion by 2025, highlighting the trend towards greener materials. Additionally, innovations such as closed-loop systems and reduced cycle times are allowing manufacturers to not only minimize waste but also improve production efficiency. This not only meets the current environmental standards but also positions companies favorably in a competitive market, aligning with the sustainability goals increasingly demanded by consumers.

| Aspect | 2023 Insights | 2025 Projections | Sustainability Practices | Market Growth Rate (%) |

|---|---|---|---|---|

| Market Size (Billion USD) | 20.5 | 25.0 | Biodegradable Materials | 10% |

| Technological Advancements | 3D Printing Integration | AI and Automation | Recycling of Plastics | 12% |

| Consumer Demand Trends | Sustainable Products | Eco-Friendly Designs | Energy Efficiency | 15% |

| Geographic Expansion | Asia-Pacific Dominance | Emerging Markets | Local Sourcing | 8% |

| Regulatory Changes | Increased Regulations | Compliance Innovations | Plastic Waste Reduction | 9% |

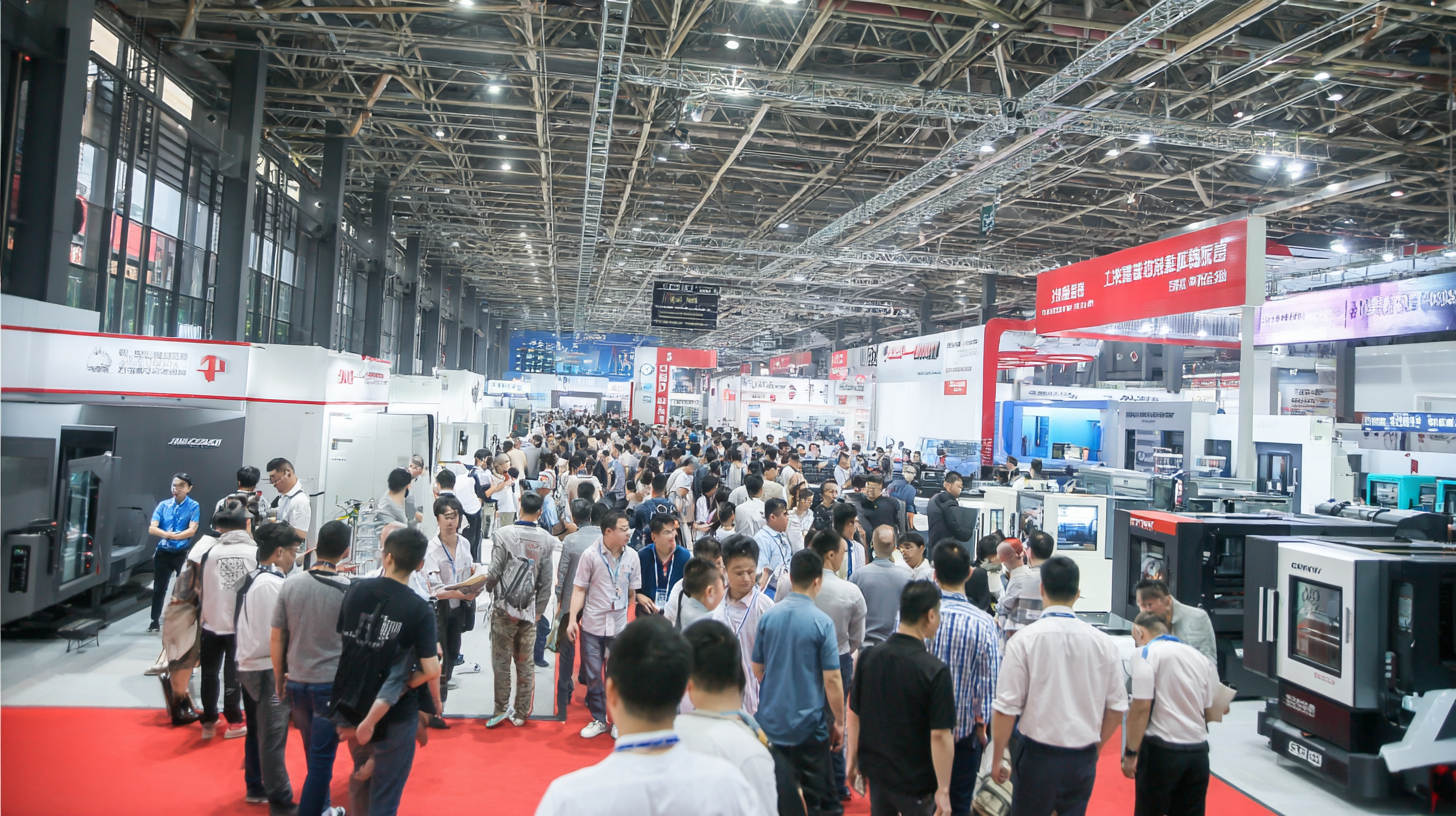

Key Players and Competitive Landscape in the Injection Molding Sector

The injection molding sector is experiencing significant growth, with the global market projected to expand from USD 365.22 billion in 2024 to USD 580.44 billion by 2033, achieving a CAGR of 4.74%. This upward trajectory is driven by rising demand across diverse applications, including automotive components and sustainable packaging solutions. Major players in the industry are strategically innovating to meet the needs of a changing market, focusing on lightweight materials and environmentally friendly practices.

As evidenced by the projections within the cyclic olefin polymers market, anticipated to reach USD 1.54 billion by 2029, the injection molding landscape is evolving to incorporate advanced materials. Concurrently, the molded plastic market is set to grow from USD 758.69 billion in 2025 to USD 1,218.39 billion by 2033, reflecting a healthy CAGR of 6.1%. This growth underscores the competitive environment where established and emerging players are vying for market share by leveraging technology to enhance production efficiency and product quality, ensuring they remain at the forefront of the injection molding industry.

Emerging Markets and Opportunities in Global Injection Molding Industry

The global injection molding market is poised for remarkable expansion, driven by surging demand across various industries. As reported, the market was valued at approximately $191 billion in 2023 and is expected to see significant growth, reaching around $365.22 billion by 2024. This upward trend illustrates the increasing reliance on injection molding technologies for efficient manufacturing processes, particularly in sectors such as automotive, consumer goods, and medical devices.

Regional dynamics reveal further opportunities, especially in emerging markets. The U.S. injection molding market is projected to be valued at $87.9 billion in 2024, while China is forecasted to reach a staggering $95.2 billion by 2030. This growth is indicative of a shifting landscape, where manufacturers are not only capitalizing on technological advancements but also adapting to new market needs. The increasing focus on sustainability, highlighted by the rising bio-polypropylene market, suggests that businesses are keen on innovating within the injection molding space to meet both consumer demands and regulatory standards.

The future of the injection molding industry looks bright, with substantial opportunities for growth and development on the horizon.

Related Posts

-

Innovative Injection Moulding Process Examples That Drive Global Procurement Efficiency

-

Understanding Injection Molding Tooling Processes and Their Industry Impact

-

Injection Moulding Process Challenges That Every Global Buyer Should Know

-

7 Essential Tips for Sourcing Plastic Parts Globally

-

How to Optimize PVC Injection Molding for Maximum Efficiency and Quality

-

Innovative Solutions for Polyvinyl Chloride Applications in Various Industries