Understanding Injection Molding Costs: Key Factors Impacting 2025 Prices

Injection molding has become a cornerstone of modern manufacturing, offering efficient and cost-effective solutions for producing a wide range of plastic components. As industries continue to evolve and demand for intricate designs increases, understanding the factors that influence injection molding costs is more critical than ever. The landscape of production is rapidly changing, and by 2025, we anticipate several key elements that will shape the pricing structure and economic viability of injection molding processes.

One of the primary aspects impacting injection molding costs is the volatile nature of raw material prices. As the market for plastics fluctuates due to supply chain disruptions and advancements in alternative materials, manufacturers must adapt to these changes, which can significantly affect overall expenses. Additionally, labor costs, technological advancements, and machine efficiency play a crucial role in determining how competitive injection molding costs will remain in the years to come.

Moreover, as sustainability becomes a priority for manufacturers, the integration of eco-friendly practices and materials might lead to new cost structures. Companies will need to navigate these complexities to ensure they remain competitive while meeting both consumer demands and regulatory requirements. This article delves into these transformative factors, providing an in-depth understanding of what to expect regarding injection molding costs in the near future.

Overview of Injection Molding and Its Applications

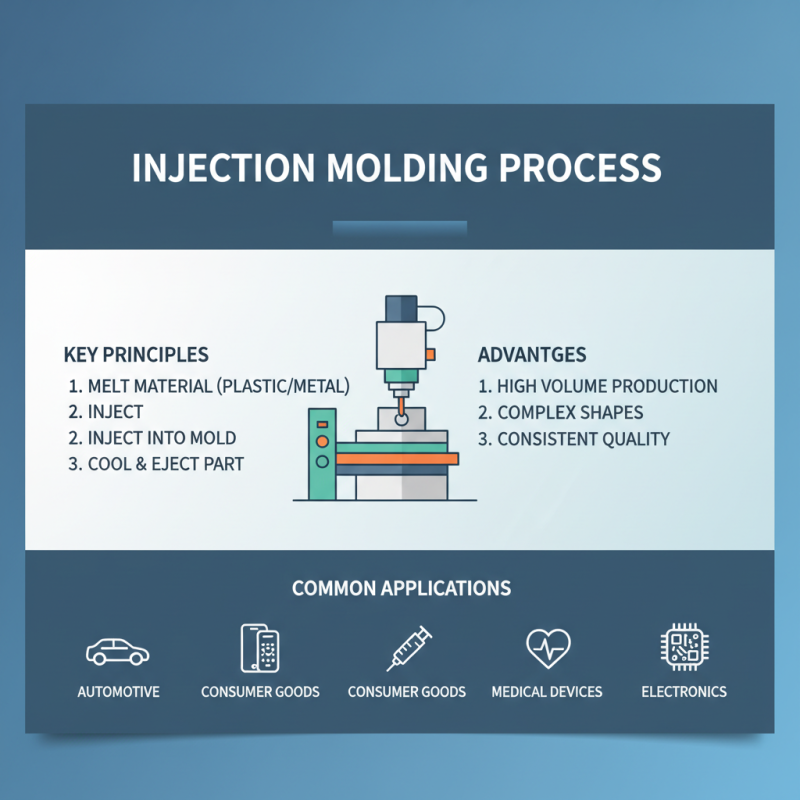

Injection molding is a widely used manufacturing process that allows for the creation of complex parts in high volumes. This technique involves injecting molten material, typically plastic, into a mold to form various shapes and designs. Injection molding is favored for its efficiency, precision, and ability to produce consistent results across numerous applications. Industries such as automotive, consumer goods, medical devices, and electronics heavily rely on this method to produce everything from intricate components to large housings.

When considering injection molding, it's essential to recognize its vast applications. For instance, in the automotive industry, components like dashboard assemblies and bumpers are often produced through this process, demonstrating its ability to meet rigorous performance standards. Similarly, consumer products like containers and toys benefit from injection molding's capability to create durable and aesthetically pleasing designs at scale.

**Tips:** To optimize your injection molding project, start by clearly defining your part specifications and requirements. This helps in selecting the right materials and ensuring the mold design will be efficient. Additionally, collaborating closely with experienced mold makers can lead to reduced production times and lower costs.

Factors Influencing Injection Molding Costs in 2025

Understanding the costs associated with injection molding in 2025 requires a comprehensive analysis of various influencing factors. Key elements include raw material prices, labor costs, and technological advancements. According to a report by MarketsandMarkets, the global injection molding market is expected to grow by approximately 5.4% annually, significantly impacted by the fluctuating prices of plastics and the rising demand for sustainable materials. As more companies shift toward eco-friendly practices, the cost implications of sourcing and utilizing recyclable raw materials will shape pricing strategies in the near future.

Another critical aspect is labor costs, which have been on the rise due to skill shortages in the manufacturing sector. A study by Deloitte highlights that the U.S. manufacturing industry could face up to 2.4 million jobs unfilled by 2028, leading to increased competition for skilled labor and thereby driving up wages. This could ultimately contribute to higher injection molding prices, as manufacturers may need to invest more in attracting and retaining talent.

Tips: To mitigate rising costs, manufacturers should consider investing in automation technologies, which not only enhance efficiency but can also reduce long-term labor expenses. Additionally, maintaining strong relationships with suppliers can lead to better negotiating power regarding material prices. Finally, conducting regular market analysis can help anticipate trends and adjust pricing strategies proactively.

Material Selection and Its Impact on Molding Expenses

Material selection plays a crucial role in determining the overall expenses associated with injection molding processes. According to a report by Research and Markets, material costs can account for up to 60% of the total injection molding expenses. The choice of material not only influences the initial procurement costs but also affects the productivity and lifecycle of molded products. Common options like thermoplastics may offer lower initial costs, but their performance and durability can lead to higher costs in terms of wastage and replacement over time.

Furthermore, different materials require varying processing temperatures and conditions, significantly impacting energy costs during production. A study from the Society of Manufacturing Engineers highlighted that using high-performance polymers can increase the energy required for molding by 20-30%. While these materials may provide superior qualities such as strength and chemical resistance, the upfront cost and energy consumption must be carefully weighed against the long-term benefits they offer. As manufacturers plan for 2025, an in-depth understanding of these material selection implications will be essential for optimizing budgets and ensuring profitability in a competitive market.

| Material Type | Cost per Kg ($) | Initial Setup Cost ($) | Cycle Time (minutes) | Material Availability |

|---|---|---|---|---|

| ABS | 2.50 | 1500 | 2 | Widely Available |

| Polycarbonate | 3.20 | 2000 | 3 | Moderately Available |

| Nylon | 3.00 | 1800 | 4 | Available |

| Polypropylene | 1.80 | 1200 | 3 | Widely Available |

| PVC | 2.00 | 1600 | 3.5 | Widely Available |

The Role of Production Volume in Cost Determination

Production volume is a critical factor in determining injection molding costs, significantly influencing both per-unit price and overall project expense. As the volume of parts produced increases, the fixed costs associated with mold creation and setup can be distributed across a larger number of units. This economy of scale often leads to a decrease in cost per part, making high-volume production more economically viable. For manufacturers, understanding their anticipated production needs is essential for calculating potential savings and optimizing budget allocations.

Furthermore, the production volume directly impacts lead times and process efficiency. High-volume runs often allow for streamlined workflows, reducing downtime and enhancing productivity. Conversely, lower production volumes might necessitate more frequent tool changes and setups, which can escalate costs and prolong manufacturing timelines. Companies must carefully assess their volume requirements to strike a balance between cost-effectiveness and supply chain responsiveness, ensuring that the injection molding process aligns with their operational goals and market demands in 2025 and beyond.

Understanding Injection Molding Costs: Key Factors Impacting 2025 Prices

The chart illustrates the estimated cost per part for different production volumes in injection molding. As the production volume increases, the cost per part decreases significantly, highlighting the importance of volume in cost determination.

Technological Advances and Their Effect on Injection Molding Prices

Technological advances play a critical role in shaping the landscape of injection molding costs, particularly as we look ahead to 2025. Automation and robotics are becoming increasingly prevalent in manufacturing processes, significantly enhancing efficiency and reducing labor costs. These innovations allow for the production of high-quality parts with precision and minimal human intervention, which can lead to substantial savings over time. Additionally, the adoption of advanced materials and superior mold-making technologies is driving down material costs while improving the durability and performance of molded components.

Moreover, the integration of Industry 4.0 concepts, such as data analytics and machine learning, is enabling manufacturers to optimize their production processes continuously. By predicting maintenance needs and minimizing downtime, companies can operate more effectively and reduce the overall costs associated with injection molding. Furthermore, the continual evolution of 3D printing technologies is set to influence the economics of mold design and prototyping, providing cost-effective methods for creating complex geometries and lower-volume production runs, ultimately impacting pricing strategies in the injection molding sector.

As these technologies advance, they will undoubtedly play a pivotal role in determining the cost structure of injection molding in the coming years.

Related Posts

-

How to Safely Recycle PVC Plastic: A Step-by-Step Guide for Sustainable Practices

-

Exploring the Versatility and Applications of PVC Film in Modern Industries

-

How to Optimize Your Production Process with Poly Plastic Solutions

-

How to Optimize PVC Injection Molding for Maximum Efficiency and Quality

-

How to Choose the Right Injection Molded Parts for Your Project

-

Ultimate Guide to Selecting the Right Injection Molding Tooling for Your Business Needs