Top Injection Molding Tooling Techniques for Efficient Production?

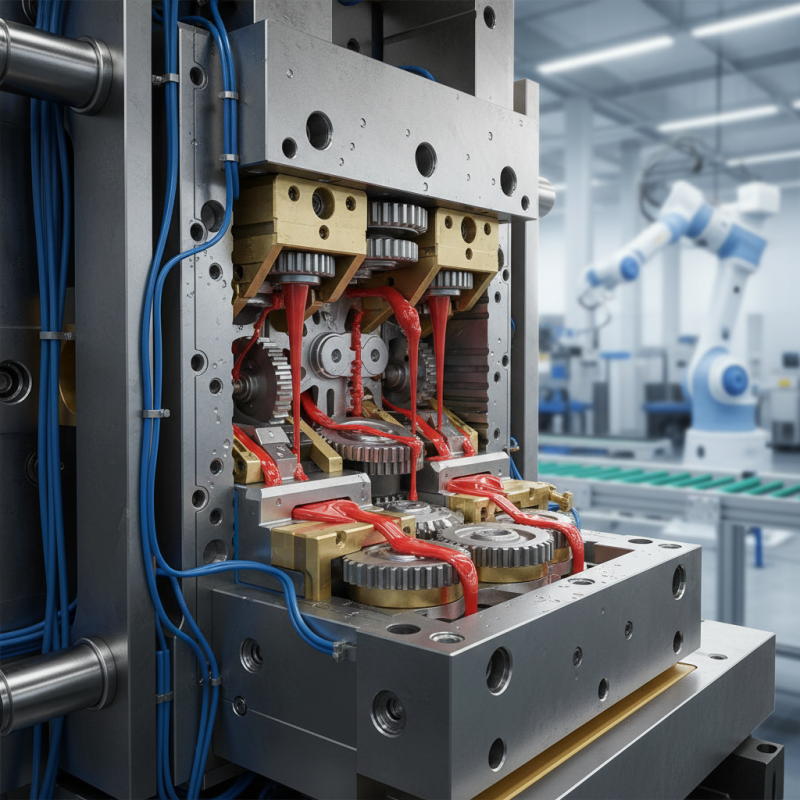

Injection molding tooling is a critical aspect of modern manufacturing. It enables the production of complex plastic parts efficiently. As industries demand more innovative products, mastering injection molding tooling becomes essential. Companies seek methods that enhance productivity without sacrificing quality.

Various techniques in injection molding tooling can streamline processes. Advanced designs contribute to reduced cycle times. Improved cooling systems lead to faster production rates. However, challenges often arise. Tool wear and maintenance can disrupt workflows. Understanding these aspects helps manufacturers make informed decisions.

Exploring optimization strategies is vital in this competitive landscape. Yet, many face issues with inefficient setups. Reflecting on these practices is necessary. The goal is to balance speed with precision in injection molding tooling. Quality should never be compromised in the pursuit of efficiency.

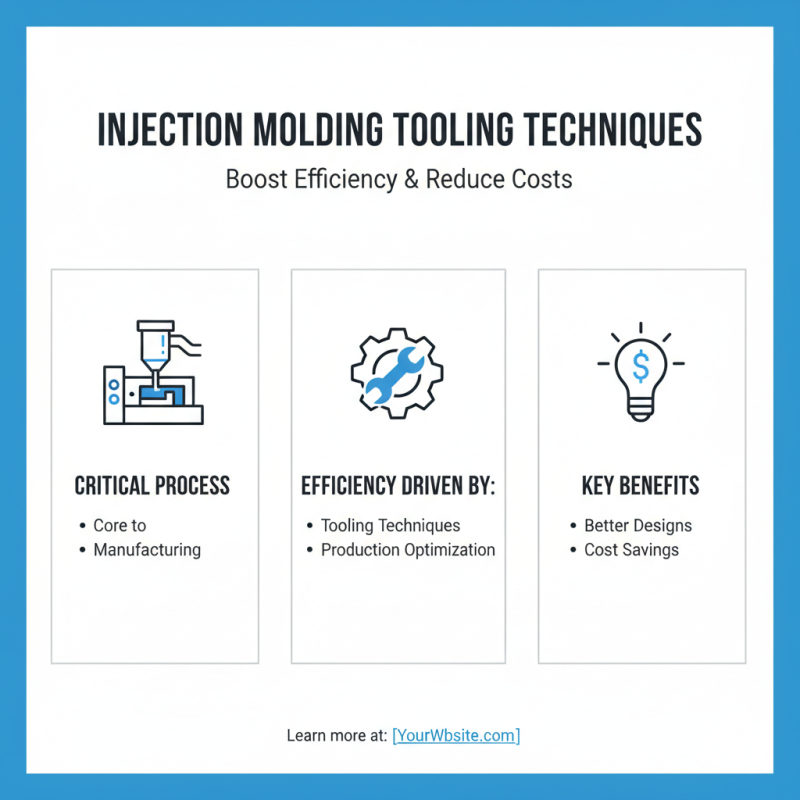

Overview of Injection Molding Tooling Techniques

Injection molding is a critical process in manufacturing. The efficiency of production relies heavily on the tooling techniques employed. Understanding various tooling methods can lead to better designs and cost savings.

For instance, one common technique is the hot runner system. It keeps the plastic molten, reducing waste. However, it can be challenging to maintain. Operators must monitor temperature closely. Another method is the use of unscrewing molds. This helps create complex shapes but can complicate the design process. These tools require careful planning to avoid production delays.

Choosing the right technique is essential. Designers often face trade-offs between speed and quality. Some techniques may yield faster results, but could risk precision. Reflection on these choices is vital. Makers need to assess both performance and durability. Each tooling method presents unique challenges and advantages that impact overall production efficiency.

Key Factors Influencing Injection Molding Tooling Efficiency

Efficient injection molding requires careful attention to tooling factors. The design of the mold plays a crucial role in production efficiency. A well-designed mold enhances the flow of molten material, ensuring thorough filling. However, even the best mold can fall short if it's not maintained properly. Regular maintenance checks are essential to prevent wear and tear that can lead to production delays.

Another important factor is the choice of materials for the molds. High-quality steel and aluminum can withstand high temperatures during production. Yet, even with good materials, it’s easy to overlook minor details in the design. Small imperfections or miscalculations can lead to defects in the final product. It's not uncommon for manufacturers to overlook the significance of cooling channels. Proper cooling is vital to minimize cycle times and improve efficiency.

Finally, the machine settings also impact tooling efficiency. Incorrect parameters can cause inconsistencies in the molded parts. Finding the right balance between pressure and temperature is not always straightforward. It requires constant tweaking and observation. Some might think they've found the perfect settings, only to experience issues later. Continuous learning and adaptation are keys to improving efficiency in the long run.

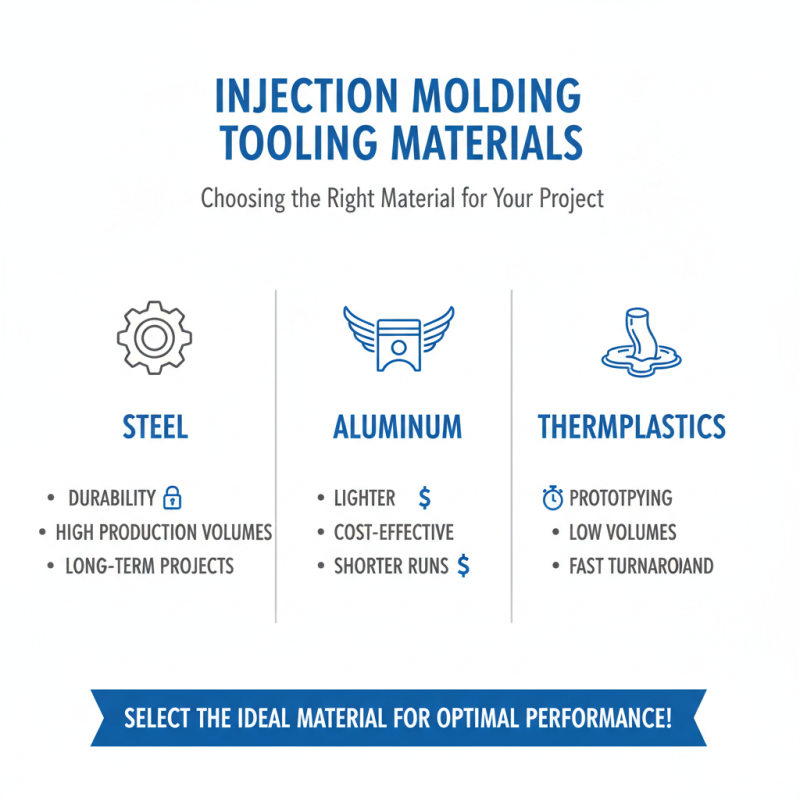

Common Materials Used in Injection Molding Tooling

When it comes to injection molding tooling, selecting the right materials is crucial. Common materials for tooling include steel, aluminum, and various thermoplastics. Steel is durable and withstands high production volumes, making it suitable for long-term projects. Aluminum, on the other hand, is lighter and more cost-effective, perfect for shorter runs.

To ensure the best results, consider the following tips. Use high-quality steel for tools that need longevity. It may cost more upfront but offers better performance and lifespan. Aluminum is great for prototypes or low-volume runs, but it might wear out quickly in high-stress applications.

Thermoplastics can also be used for specific applications. They are versatile and can be customized for unique needs. However, not all thermoplastics are suitable for every project. Testing your chosen material's performance early can help identify issues before they arise. Remember, the right choice minimizes flaws and optimizes efficiency.

Innovative Techniques for Reducing Production Time

Reducing production time in injection molding is crucial. Many manufacturers are exploring innovative techniques to achieve this goal. One approach is the use of hot runner systems. These systems keep the plastic molten, reducing cycle times significantly. They minimize waste and enhance efficiency. However, they come with higher initial costs and require careful maintenance.

Another technique is optimizing the cooling process. Advanced cooling designs shortens the time needed for molds to cool down. This means less waiting and more production. Utilizing conformal cooling channels can improve the cooling efficiency effectively. Yet, the design and implementation can be challenging and costly.

Finally, embracing automation can streamline the entire injection molding process. Robotics can assist in loading materials and handling parts. This cuts down manual labor and speeds up production. However, the integration of automation may require training and adjustment for the workforce. Balancing these innovative techniques with practical considerations is key for many manufacturers.

Top Injection Molding Tooling Techniques for Efficient Production

| Technique | Description | Benefits | Production Time Reduction (%) |

|---|---|---|---|

| Rapid Prototyping | Using 3D printing to create molds quickly for testing designs. | Faster design validation and reduced time to market. | 30% |

| Multi-Cavity Molds | Molds that allow the production of multiple identical parts in a single cycle. | Increased output per cycle, leading to fewer cycles needed. | 50% |

| Hot Runner Systems | A system that keeps the plastic molten as it moves through the mold to the cavity. | Reduced cycle times and less material waste. | 20% |

| Inline Production | Combining several production stages in a single line to minimize handling. | Streamlined process, reducing work in progress and idle time. | 40% |

| Simulation Software | Using software to predict mold behavior before physical production. | Identifies potential issues early, reducing trial and error. | 25% |

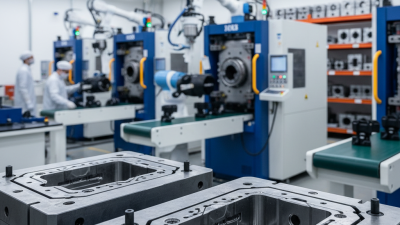

Best Practices for Tool Maintenance and Upgrades

Tool maintenance is crucial for maximizing the efficiency of injection molding processes. Regular checks can identify wear and damage that affect production quality. For example, a small crack can lead to material leaks, causing defects. Cleaning molds regularly prevents buildup that can alter dimensions. Neglecting this maintenance can result in costly downtime and product recalls.

Upgrading tools is another critical aspect. Technology evolves, and older molds may lag behind. Implementing modern features like temperature control can improve consistency. However, upgrades require careful planning and budgeting. Inadequate funding can lead to half-finished upgrades, causing inefficiencies. It's essential to balance innovation with resource allocation, ensuring that every upgrade offers tangible benefits.

Reflecting on common practices, many overlook the importance of detailed record-keeping. Tracking maintenance schedules and repair history fosters a proactive approach. Without records, it’s easy to miss patterns in tool performance issues. Relying on memory can lead to oversights. Establishing a systematic approach to maintenance ensures tools are always ready for optimized production.

Related Posts

-

Ultimate Guide to Selecting the Right Injection Molding Tooling for Your Business Needs

-

Innovative Injection Moulding Process Examples That Drive Global Procurement Efficiency

-

Exploring Trends in Injection Molding Materials at the 138th Canton Fair 2025

-

Top 10 Essential Injection Molding Tooling Techniques for Efficient Production

-

How to Choose the Right Injection Molding Tooling for Your Project

-

Top 10 Tips for Successful Injection Molding of Small Parts?