Top 10 Tips for the Injection Moulding Process Success?

The injection moulding process plays a crucial role in the manufacturing landscape. With global estimates revealing the industry is expected to reach USD 375 billion by 2027, success in this field is paramount. Increasing efficiency and maintaining quality are essential goals for manufacturers striving to meet the growing demand.

Achieving success in the injection moulding process requires strategic planning and implementation of best practices. According to recent industry reports, nearly 30% of production waste can be attributed to inefficiencies in the moulding process. This points to an urgent need for companies to evaluate their methods critically. Focusing on optimizing cycles, selecting appropriate materials, and investing in skilled labor can minimize errors significantly.

Despite advancements, many manufacturers still face challenges. These may include design flaws or miscalculations during production. Reflecting on these issues is vital for continuous improvement. Embracing innovative solutions and learning from past setbacks can drive future success in the injection moulding industry.

Understanding the Basics of Injection Moulding Process

The injection moulding process forms an essential pillar of modern manufacturing. Understanding it can lead to enhanced efficiency and quality. At its core, injection moulding involves melting plastic pellets and injecting them into molds. According to industry reports, the global injection moulding market is projected to reach USD 500 billion by 2027, emphasizing its significance.

Focus on the material selection. Choosing the right raw material can significantly impact product performance. For instance, thermoplastics can provide greater flexibility than thermosets. Address potential issues like material flow and shrinkage in your design. Precision is vital when creating the mould to ensure proper functionality.

Another tip is to control temperature carefully. Overheating can degrade materials. Underheating may lead to incomplete forms. Maintaining the right temperature can enhance the final product's quality. Monitor pressure levels during injection to avoid common defects.

Many companies overlook the importance of maintenance. Regularly servicing machines can mitigate breakdowns, leading to costly downtimes. A poorly maintained machine can inflate production costs and compromise quality. Reflection on processes is crucial; continual improvement is key.

Selecting the Right Materials for Optimal Results

Selecting the right materials is crucial for the success of the injection moulding process. The choice of resin can drastically affect product quality and manufacturing efficiency. According to recent industry reports, nearly 70% of production issues stem from improper material selection. This statistic highlights the importance of aligning material properties with product requirements.

When choosing materials, it’s essential to understand their characteristics. For example, thermoplastics like polypropylene are known for their flexibility, while polycarbonate offers superior strength and transparency. Use these specific traits to meet your design goals. However, remember that not all grades of a single material are equal. A common misstep is assuming that a more expensive grade always means better performance.

Consider these tips for optimal results:

- Evaluate your production volume and cycle times when selecting materials.

- Materials that perform well in high-volume runs might not be suitable for smaller batches.

- Testing materials under varying conditions can reveal potential weaknesses.

You might discover unexpected behaviors that lead to costly adjustments down the line. Balancing cost, performance, and aesthetics is a nuanced task, and small oversights in material choice can have large implications.

Importance of Machine Settings and Parameters in Injection Moulding

In injection moulding, machine settings and parameters play a crucial role in determining the success of the process. According to the Plastics Industry Association, proper adjustments can reduce defects by up to 30%. Key parameters include temperature, pressure, cooling time, and injection speeds. Each of these factors must align with the specific material used. Failing to do so can lead to significant quality issues.

Tip: Monitor the barrel temperature closely. A variation of even a few degrees can affect the material's flow properties. Incorrect settings often result in inconsistent product quality.

Another important aspect is the injection speed. Too fast can lead to defects like jetting, while too slow can cause incomplete filling. A delicate balance is necessary; slight miscalculations can waste materials or increase production costs.

Tip: Regularly calibrate the machines. Ongoing checks can prevent long-term errors in product output, saving time and resources. Neglecting this step may lead to unexpected breakdowns or poor-quality results. Proper machine settings are not just technical; they directly impact overall efficiency and profitability in production.

Top 10 Tips for the Injection Moulding Process Success

| Tip Number | Tip Description | Importance Level |

|---|---|---|

| 1 | Optimize machine temperature settings for material. | High |

| 2 | Adjust injection speed based on part complexity. | Medium |

| 3 | Maintain consistent back pressure during injection. | High |

| 4 | Use the correct mold release agents. | Medium |

| 5 | Regularly calibrate injection molding equipment. | High |

| 6 | Control cooling time accurately to avoid defects. | High |

| 7 | Implement a proper mold design for optimal flow. | High |

| 8 | Ensure the use of quality raw materials. | High |

| 9 | Monitor the cycle time constantly. | Medium |

| 10 | Train operators on advanced machine features. | Medium |

Designing Efficient Moulds for Enhanced Production Quality

In the injection moulding industry, designing efficient moulds is crucial for production quality. Research shows that poorly designed moulds can lead to a 30% increase in processing costs. In contrast, optimized mould designs reduce material waste and enhance product consistency. This is essential in competitive markets where every penny counts.

The choice of materials for mould construction directly impacts production efficiency. Steel moulds offer durability but are more expensive. Aluminum moulds, on the other hand, are cost-effective but may wear out faster. Manufacturers must weigh these factors carefully. A recent survey indicated that 78% of engineers believe that advanced simulation tools help in mould design, leading to better outcomes.

However, not all designs are perfect. Many companies still face issues like air traps and inadequate cooling channels. These flaws can cause defects in the final product, affecting customer satisfaction. Continuous learning and adaptation in design practices are necessary. Many companies report that regular reviews and updates of their mould designs can significantly enhance the overall production quality.

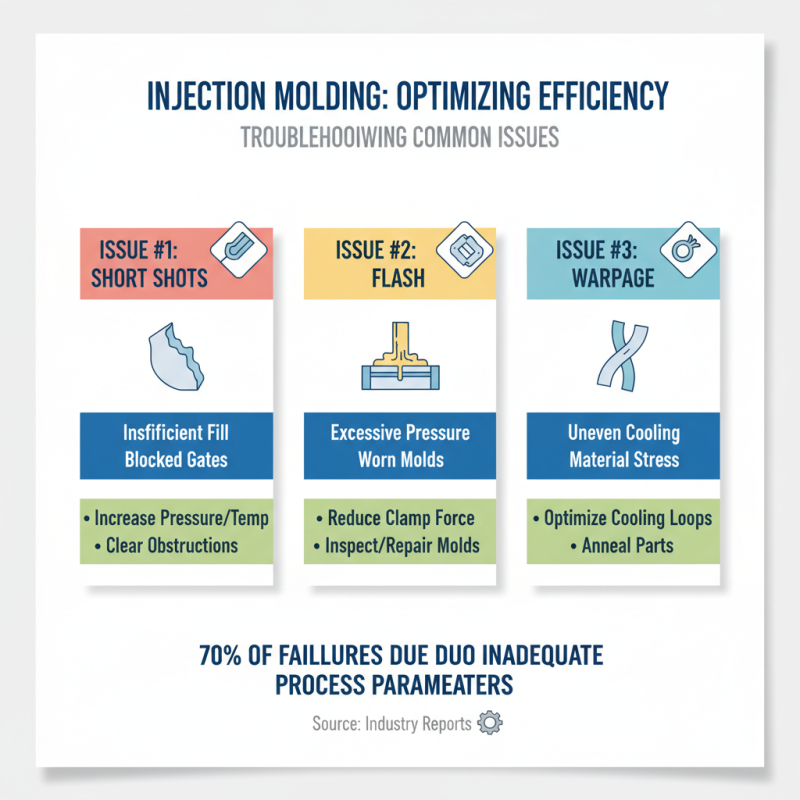

Troubleshooting Common Issues in Injection Moulding Operations

Troubleshooting common issues in injection moulding operations can significantly improve production efficiency. According to industry reports, up to 70% of failures can be traced back to inadequate process parameters. Proper analysis of these factors is crucial.

Temperature control is vital. If the melt temperature is too low, it may lead to incomplete filling. Conversely, excessive heat can create defects. Regularly maintain your heating elements. Inspect them to ensure they are functioning properly. This simple action can save hours of downtime.

Another frequent issue is air trapping. This leads to voids and weak spots in the final product. Ensure vents are adequately designed and placed. However, even with the best designs, problems may arise. Continuous monitoring during the fill phase is essential.

Setting up an effective feedback loop can help identify and solve issues in real-time. Use monitoring tools to track metrics like pressure and flow rate. Small adjustments can lead to significant improvements. Remember, flexibility in your approach is key.

Related Posts

-

How to Choose the Right Injection Molding Tooling for Your Project

-

Innovative Injection Moulding Process Examples That Drive Global Procurement Efficiency

-

Injection Moulding Process Challenges That Every Global Buyer Should Know

-

What is Low Cost Injection Molding and How it Revolutionizes Manufacturing Efficiency

-

7 Reasons Why Polypropylene Injection Molding is the Best Choice for Your Project

-

How to Optimize PVC Injection Molding for Maximum Efficiency and Quality