Innovative Techniques for Optimizing Design for Injection Molding in Modern Manufacturing

In the realm of modern manufacturing, the significance of "design for injection molding" cannot be overstated. As industries evolve, optimizing injection molding design has become essential for enhancing efficiency, reducing costs, and improving product quality. According to renowned expert Dr. John Matthews, a leading figure in injection molding technology, “Effective design for injection molding not only streamlines production but also creates innovative products that meet today's demanding market standards.” His insights highlight the critical role that innovative techniques play in refining the design process.

As manufacturers strive to remain competitive, understanding the intricate relationship between design and production is paramount. Modern innovations—ranging from advanced software simulations to material science breakthroughs—are reshaping how products are conceived and manufactured. By integrating these techniques, designers can anticipate potential challenges and develop solutions that integrate seamlessly into the injection molding process.

Emerging Trends in Injection Molding Design Optimization Techniques

The field of injection molding is evolving rapidly, with emerging trends that focus on enhancing design optimization techniques. Advanced simulation tools are now being widely adopted, allowing manufacturers to predict the behavior of materials during the molding process. According to a recent report from the Society of Plastics Engineers, up to 40% of design flaws can be identified and corrected in the early stages of product development through these simulations, significantly reducing costs associated with material waste and rework.

Another notable trend is the integration of additive manufacturing with traditional injection molding processes. This hybrid approach enables manufacturers to create complex geometries that were previously unachievable. A study by Grand View Research highlights that the combination of these technologies could lead to a projected growth rate of 10.5% in the injection molding market over the next five years. This indicates that businesses are increasingly prioritizing innovative design strategies to stay competitive.

Tip: When optimizing your injection molding design, consider implementing design for manufacturability (DFM) guidelines early in the process. This practice can help streamline the production process and minimize potential issues down the line.

Tip: Invest in training for your design and engineering teams on the latest simulation software, as proficiency in these tools can drastically improve design accuracy and efficiency.

Utilization of Advanced Materials for Enhanced Molding Efficiency

The utilization of advanced materials in injection molding is revolutionizing modern manufacturing processes. These materials, which include thermoplastics, composites, and biodegradable options, offer enhanced properties such as improved strength, flexibility, and temperature resistance. By integrating these innovative materials, manufacturers can optimize designs that not only meet the specific requirements of their applications but also streamline the production process. This results in reduced cycle times and lower waste generation, significantly improving overall efficiency.

Moreover, advanced materials facilitate the production of intricate designs that were previously challenging to achieve. For instance, the use of lightweight but strong composites allows for the creation of complex geometries without compromising structural integrity. Additionally, the incorporation of smart materials that respond to environmental changes can lead to the development of adaptive components, further pushing the boundaries of injection molding capabilities. This shift not only enhances product performance but also encourages sustainability by reducing the reliance on traditional, less efficient materials.

Impact of Simulation Software on Injection Molding Design Processes

In the realm of modern manufacturing, the application of simulation software has revolutionized the design processes for injection molding. This technology allows engineers and designers to create virtual prototypes that can be analyzed for performance and efficiency before any physical production begins. By leveraging advanced algorithms and modeling techniques, simulation software enables the identification of potential defects and design flaws, leading to a more refined and optimized final product.

Moreover, simulation tools facilitate the exploration of various design alternatives in a cost-effective manner. Designers can assess different materials, geometries, and processing conditions to determine the most effective combination for a specific application. This iterative process reduces the need for extensive physical testing, significantly saving both time and resources. As a result, the impact of simulation software extends beyond mere design enhancements; it fosters innovation and accelerates the development cycle in the competitive field of injection molding.

Integrating Sustainable Practices in Injection Molding Design Optimization

In today's manufacturing landscape, integrating sustainable practices in injection molding design optimization is crucial for creating environmentally friendly products. One effective technique involves using biodegradable materials in the design phase. By selecting polymers that are not only efficient for production but also break down naturally, manufacturers can significantly reduce the ecological footprint of their products. This shift not only addresses environmental concerns but also aligns with consumer demand for sustainable goods.

Another innovative approach is the implementation of energy-efficient processes in the injection molding cycle. This can be achieved through optimizing machine settings and using advanced technologies, such as electric injection molding machines that consume less energy compared to their hydraulic counterparts. Additionally, incorporating design elements that minimize waste, such as optimizing the layout of parts in the mold, can lead to reduced scrap rates and lower material usage. These strategies not only enhance the sustainability of the production process but also improve cost efficiency and resource management in modern manufacturing.

Case Studies: Successful Implementation of Innovative Molding Techniques

The evolution of injection molding techniques in modern manufacturing showcases remarkable advancements, particularly in the case studies emphasizing the successful implementation of innovative molding methods. A significant development includes the breakthrough in micro-lens array molding technology, which leverages Moldex3D analysis for optimizing flow channel designs. This technique has increased material utilization rates substantially, making it possible to produce intricate designs with high precision.

Tips: When adopting new molding techniques, it's essential to invest in software analytics tools that facilitate simulation and optimization. Additionally, training your workforce on the latest technologies can significantly enhance your production efficiency and product quality.

Moreover, the ongoing policy support for the magnesium industry in 2024 reflects a broader trend toward sustainable and high-end manufacturing practices. As companies navigate these changes, incorporating innovative approaches into injection molding can lead to more effective resource management and product development, aligning with global standards in manufacturing excellence.

Innovative Techniques for Optimizing Design for Injection Molding

This chart illustrates the percentage of success rates for various innovative molding techniques implemented in modern manufacturing.

Related Posts

-

Exploring the Versatility of PVC Plastic: Innovative Applications in Modern Design

-

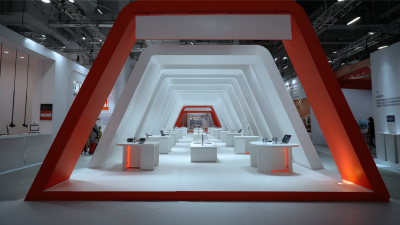

Exploring Trends in Injection Molding Materials at the 138th Canton Fair 2025

-

How to Choose the Right Injection Molding Materials for Your Project Success

-

Exploring the Future of Plastic Angle Products at the 138th Canton Fair 2025 in China

-

Exploring the Versatility and Applications of PVC Film in Modern Industries

-

How to Safely Recycle PVC Plastic: A Step-by-Step Guide for Sustainable Practices