Top Uses of Plastic Angle in Construction and Home Improvement Projects

In the ever-evolving landscape of construction and home improvement, the utilization of innovative materials is key to achieving efficiency and sustainability. One such material that has gained immense popularity is "plastic angle." Renowned industry expert Dr. Linda Harper, a leading authority on construction materials, emphasizes the importance of this versatile item, stating, "Plastic angles provide unmatched durability and flexibility, making them ideal for a variety of applications in both residential and commercial projects."

Plastic angle is not only lightweight but also resistant to corrosion, making it a prime choice for creating structures that require strength without the burden of heavy traditional materials. Its application ranges from framing to supporting structures, as well as providing precise angles in cabinetry and furniture design. As homeowners and construction professionals alike seek to enhance their spaces with practical yet sustainable materials, the demand for plastic angle continues to rise, redefining the standards of modern building practices. The versatility of plastic angle proves it to be an invaluable asset in any construction toolkit, paving the way for innovative designs and efficient project execution.

Essential Attributes of Plastic Angle for Construction Projects

Plastic angles are increasingly recognized for their versatility and practicality in construction and home improvement projects. One of their essential attributes is their lightweight nature, which significantly reduces transportation and installation costs. According to a report from the Plastics Industry Association, the use of plastic materials in construction can lower project weight by up to 50%, facilitating easier handling and reducing the structural load on building frameworks. This characteristic is particularly beneficial in remodeling jobs or renovations where existing structures must be preserved while improving functionality.

Moreover, plastic angles offer superior resistance to moisture, corrosion, and chemicals, making them ideal in environments prone to humidity or exposure to harsh substances. A study published in the Journal of Building Materials highlights that plastic components can extend the lifespan of structures and reduce maintenance costs by up to 30% over time. This durability combined with low maintenance requirements makes plastic angles a sound investment for both large-scale construction and DIY projects.

Tips: When selecting plastic angles for your project, consider the specific environmental conditions they will face. For outdoor applications, choose UV-resistant materials to prevent degradation from sunlight. For wet environments, verify that the plastic type offers maximum resistance to water and chemicals to ensure longevity.

Common Applications of Plastic Angle in Home Improvement

Plastic angle, a versatile material, finds numerous applications in home improvement projects, enhancing both functionality and aesthetics. One common use is as trim or molding along walls and ceilings. It provides a clean and neat finish to corners, making spaces look organized and polished. Additionally, plastic angles serve as corner protectors, safeguarding drywall or plaster during renovations and everyday wear and tear.

Another significant application of plastic angle is in creating custom shelving units or supports. Homeowners can utilize these lightweight materials to build sturdy frameworks for shelves in garages, workshops, or even living rooms. The ease of cutting and shaping plastic angle allows for creative freedom in design, making it an attractive choice for DIY enthusiasts. Furthermore, its resistance to moisture and decay makes it ideal for use in areas prone to humidity, such as basements or bathrooms, ensuring that projects remain durable over time.

Top Uses of Plastic Angle in Construction and Home Improvement Projects

| Application | Description | Advantages | Common Materials |

|---|---|---|---|

| Edge Trimming | Used to create a finished edge on surfaces like countertops and tables. | Provides a clean and professional look, easy to clean. | PVC, Polypropylene |

| Supports and Reinforcements | Used in constructing framework and supports for shelves and cabinetry. | Lightweight yet strong, resistant to moisture. | Polyethylene, Nylon |

| Dividers and Partitions | Used to create temporary or permanent divisions in spaces. | Easy to install, customizable sizes and shapes. | Acrylic, PVC |

| Protection for Edges | Used to protect the edges of furniture or fixtures from chipping. | Durable and helps maintain appearance. | Polycarbonate, PVC |

| Waterproofing | Used in areas requiring moisture resistance like basements. | Long-lasting, prevents mold and mildew. | HDPE, PVC |

Comparative Advantages of Plastic Angle vs. Traditional Materials

Plastic angles have emerged as a favored choice in construction and home improvement projects due to their unique advantages over traditional materials. A recent industry report indicates that the global plastic materials market is expected to grow at a CAGR of 5.1% through 2027, reflecting an increasing adoption of plastics in various applications, including construction. Plastic angles, made from durable materials like PVC or polyethylene, are resistant to rot, corrosion, and weathering, making them ideal for both indoor and outdoor uses.

When comparing plastic angles to traditional materials such as wood or metal, the differences in maintenance and longevity become apparent. For instance, plastic angles do not require the same level of upkeep as wood, which is prone to warping and insect damage. According to a survey by the American Society of Civil Engineers, structures using plastic components tend to require 25-30% less maintenance over their lifespan compared to those constructed with conventional materials. Additionally, the lightweight nature of plastic angles allows for easier handling and installation, reducing labor costs and project timelines — an essential factor in today’s fast-paced construction environment. This shift towards plastic components highlights a significant trend towards efficient, sustainable materials in construction.

Comparison of Plastic Angle and Traditional Materials

This bar chart illustrates the comparative advantages of Plastic Angle versus traditional construction materials such as Wood, Metal, and Concrete across various dimensions including weight, cost, and lifespan. Plastic Angle proves to be a lightweight and cost-effective material with a considerable lifespan, making it an attractive option for construction and home improvement projects.

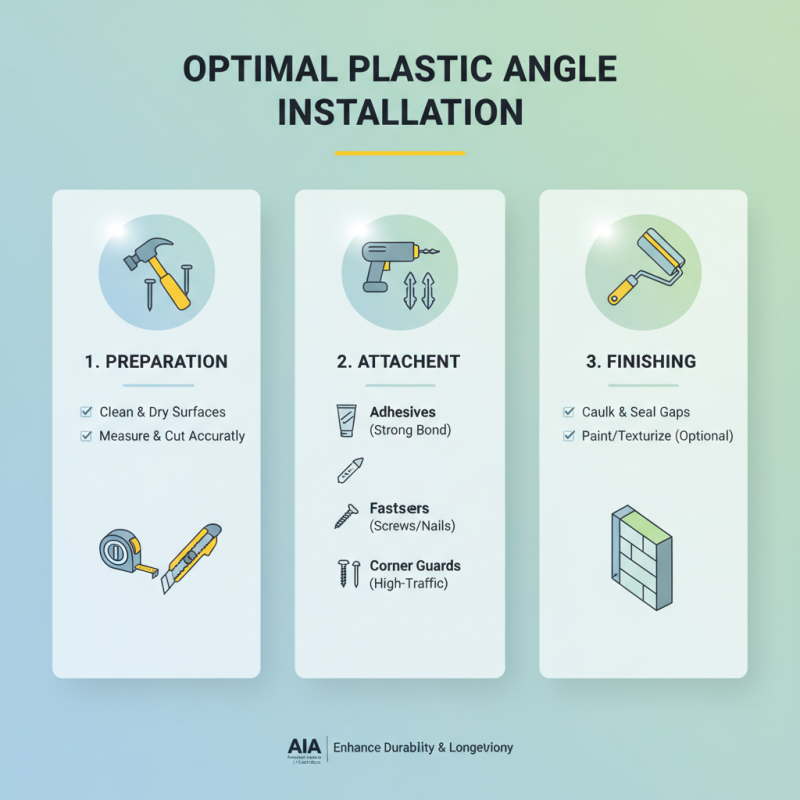

Installation Techniques for Plastic Angle in Various Settings

When it comes to installation techniques for plastic angle in various settings, understanding the methods that ensure optimal performance is crucial. Plastic angles are versatile and lightweight, making them ideal for a wide array of construction and home improvement projects. The American Institute of Architects (AIA) reports that using plastic angles can significantly enhance the longevity and durability of finished structures. For instance, in residential renovations, plastic angles can be attached to corners and edges to provide structural support and prevent wear in high-traffic areas, effectively extending the life of architectural features.

Installation can vary depending on the application. In drywall installations, plastic angles can be secured using adhesive or screws directly into the studs or the structure itself. The National Association of Home Builders (NAHB) emphasizes that proper alignment and leveling during installation are critical to achieving an aesthetically pleasing finish. For outdoor applications, such as fencing or garden borders, the angles may be anchored into the ground with concrete or gravel bases, ensuring stability against weather conditions. Additionally, maintenance is minimal; regular cleaning is often enough to keep plastic angles functional and visually appealing. These techniques not only promote structural integrity but also cater to aesthetic demands in modern design.

Maintenance Tips for Longevity of Plastic Angle Components

When using plastic angle components in construction and home improvement projects, proper maintenance is essential to ensure longevity and optimal performance. Regular inspection is key; check for any signs of wear or damage, such as cracks or discoloration. Cleaning the plastic angles with mild soap and water can help remove dirt and prevent the accumulation of grime that may lead to deterioration. Avoid abrasive cleaners or tools, as these can scratch the surface and compromise the material's integrity.

Additionally, proper storage of plastic angle pieces is crucial. Keep them in a temperature-controlled environment to prevent warping or bending, particularly in extreme weather conditions. If they are used outdoors, consider applying a UV protectant or shade to minimize exposure to harsh sunlight, which can cause fading and brittleness over time. By following these maintenance tips, you can maximize the life of plastic angle components, ensuring they continue to provide functional support in your construction and home improvement endeavors.

Related Posts

-

Exploring the Future of Plastic Angle Products at the 138th Canton Fair 2025 in China

-

Top Strategies for Optimizing Plastic Angle Products in Your Business

-

Exploring the Impact of Plastic Angle Innovation at the 138th Canton Fair in 2025

-

How to Choose the Right PVC Film for Your Packaging Needs

-

Unveiling the Advantages of Polypropylene Plastic: A Game Changer for Modern Manufacturing

-

Ultimate Guide to Selecting the Right Injection Molding Tooling for Your Business Needs