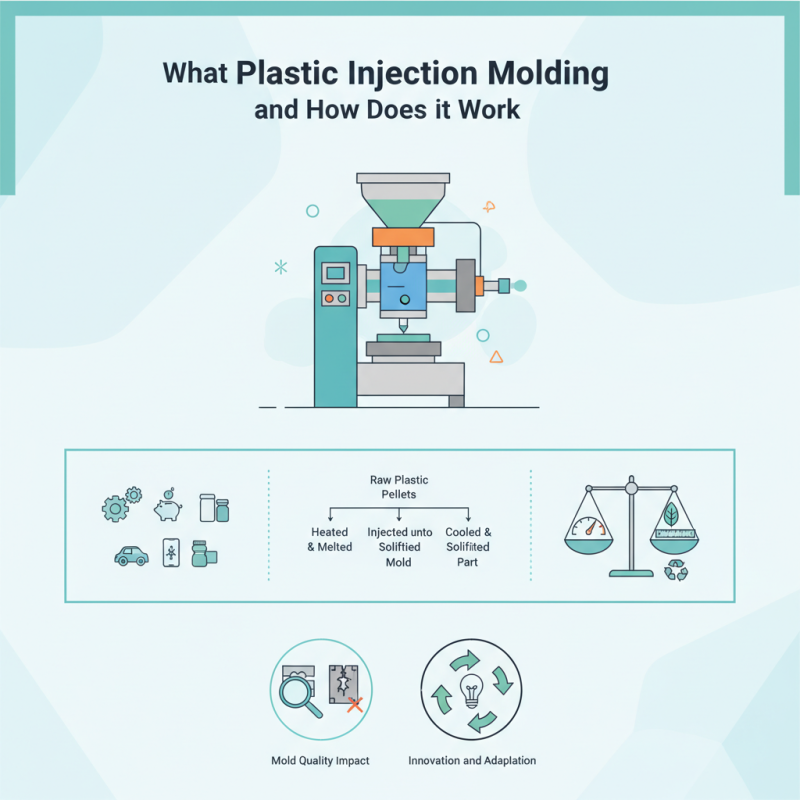

What is Plastic Injection Molding and How Does it Work?

Plastic injection molding is a key process in manufacturing. This method allows various products to be created efficiently and cost-effectively. According to industry expert John Smith, “Plastic injection molding is the backbone of modern production.” His perspective highlights its crucial role in diverse sectors.

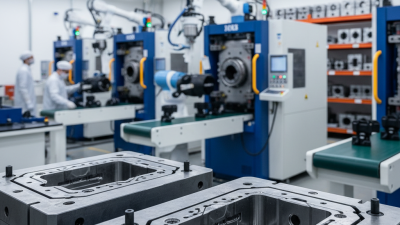

In this process, plastic is heated and injected into molds. Once cooled, it takes the shape of the mold. This method is popular due to its speed and precision. Many everyday items, from toys to automotive parts, are produced this way. However, challenges exist. The quality of molds can heavily impact the final product.

While plastic injection molding offers numerous advantages, it requires careful planning. Design flaws can lead to significant waste. Moreover, not every material works well in this process. Manufacturers must constantly innovate and adapt. Balancing efficiency and sustainability is essential. Understanding these aspects is vital for anyone involved in the industry.

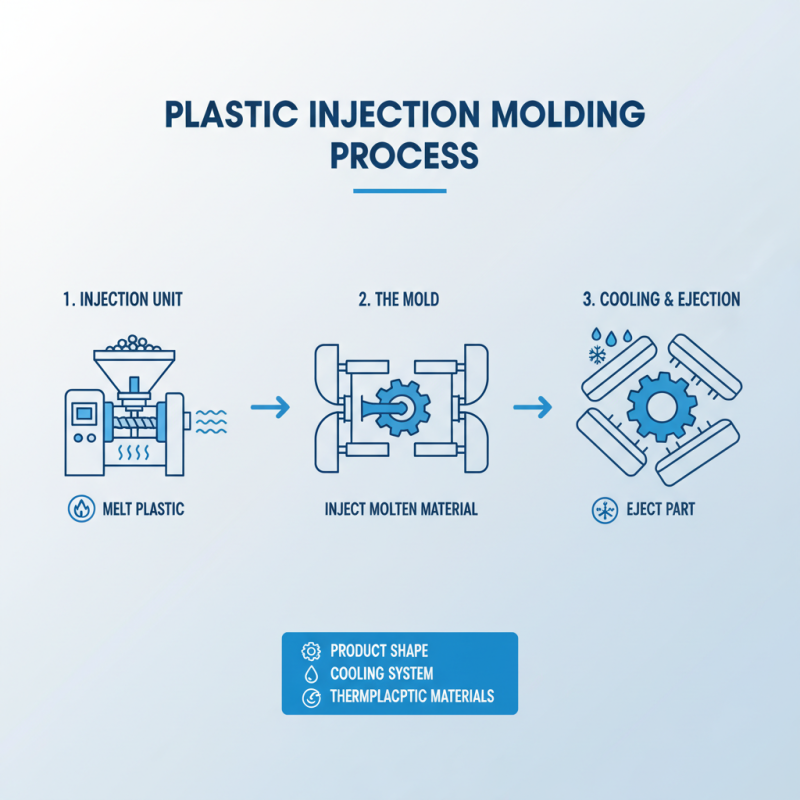

Definition of Plastic Injection Molding and Its Key Components

Plastic injection molding is a manufacturing process used to create parts from thermoplastic materials. The process involves melting plastic pellets and injecting this molten material into a mold. This mold contains the shape of the desired product. Key components of the system include the injection unit, the mold, and the cooling system.

In the injection unit, the plastic is heated to a specific temperature. The temperature is crucial. If it’s too low, the plastic won’t flow. If it’s too high, it can degrade. The mold is often made from steel or aluminum, designed to withstand high pressure.

Tip: Always consider the cooling time. This step can significantly affect production speed and part quality.

After cooling, the mold opens, and the finished part is ejected. Sometimes, imperfections occur. These might include uneven surfaces or incomplete filling. Regular mold maintenance helps minimize such issues.

Tip: Regularly inspect molds for wear. Small problems can lead to larger defects over time. Understanding these key components helps improve the injection molding process.

The Process of Plastic Injection Molding: Step-by-Step Overview

Plastic injection molding is a widely used manufacturing process. It involves several key steps that ensure precision and efficiency. The journey begins with melting plastic pellets. These pellets are heated until they become a liquid. The molten plastic is then injected into a mold cavity. The pressure used during this step must be just right. Too much pressure can lead to defects.

After the injection, the plastic cools and solidifies. This phase is crucial. If the cooling is uneven, the final product may warp. Once cooled, the mold opens to release the part. The entire process can seem straightforward, but challenges often arise. Operators need to monitor temperature and pressure closely. Even minor fluctuations can affect product quality.

Next, the parts may need trimming or finishing. This part can be meticulous. Small imperfections can ruin the aesthetic or function of the product. It’s essential to catch these issues early. Throughout the process, constant observation and adjustment are needed. Mistakes and imperfections can serve as important learning points. Each cycle is not just a repeat; it's an opportunity for improvement.

Plastic Injection Molding Production Data

This bar chart illustrates the production volume of plastic injection molded products from 2018 to 2022. As shown, there has been a steady increase in production each year, indicating growing demand in the industry.

Types of Plastics Used in Injection Molding Applications

Injection molding is a widely used manufacturing process for creating plastic parts. Understanding the types of plastics used is essential for optimizing applications. Common plastics include ABS, polypropylene, and polycarbonate. Each material possesses unique properties that cater to specific needs.

ABS is favored for its strength and durability. It can withstand impact and is lightweight. In fact, its toughness makes it suitable for automotive components and consumer products. Polypropylene, on the other hand, offers excellent chemical resistance and flexibility. This makes it ideal for packaging and medical applications, often seen in disposable syringes and containers.

Polycarbonate, known for its transparency and high impact resistance, is another significant player. It's often used in safety glasses and electronic housings. According to industry reports, the global plastic injection molding market is projected to reach approximately 300 billion USD by 2025. However, as demand grows, challenges like waste management and sustainability arise. The environmental impact of plastic production remains an ongoing concern that industry leaders must address.

What is Plastic Injection Molding and How Does it Work?

| Type of Plastic | Properties | Common Applications |

|---|---|---|

| Polyethylene (PE) | Lightweight, chemical-resistant, flexible | Bottles, bags, containers |

| Polypropylene (PP) | Durable, resistant to fatigue and chemicals | Automotive parts, medical containers |

| Polyvinyl Chloride (PVC) | Versatile, good weather resistance | Pipes, window profiles, flooring |

| Polystyrene (PS) | Brittle, easy to mold, inexpensive | Packaging, disposable cutlery, toys |

| Acrylonitrile Butadiene Styrene (ABS) | Strong, impact-resistant, good surface finish | Lego bricks, automotive parts, appliances |

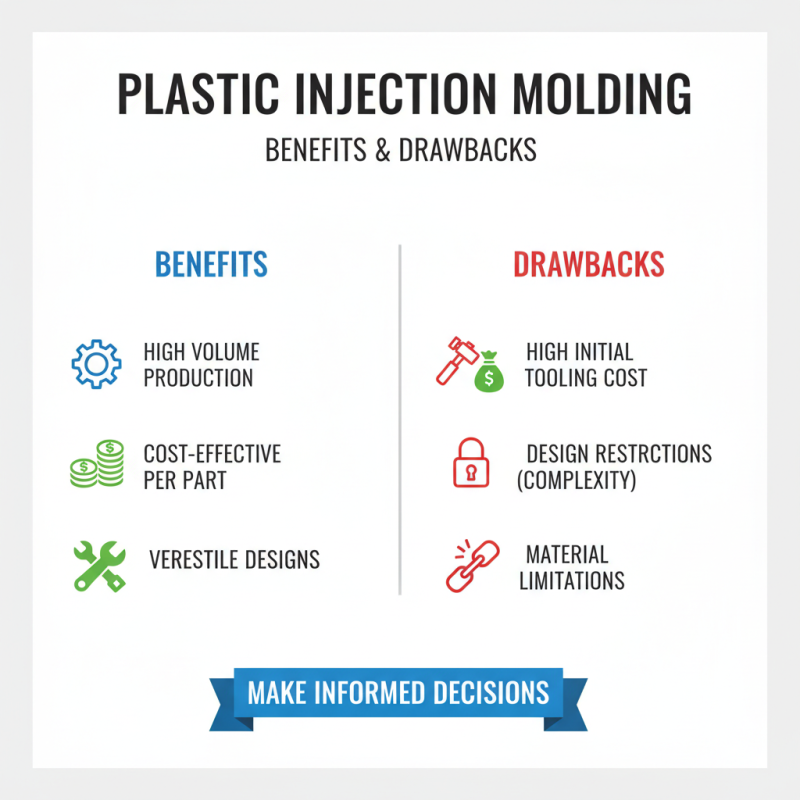

Advantages and Disadvantages of Plastic Injection Molding

Plastic injection molding is widely used. It offers both benefits and drawbacks. Understanding these can help in making informed decisions.

One major advantage is efficiency. High production rates are possible. Complex shapes can be created easily. The process is often automated. This reduces labor costs. However, initial setup costs can be high. The machinery and molds require significant investment. A small design flaw can lead to large-scale issues.

On the flip side, flexibility is limited. Changing designs can be costly and time-consuming. Waste material is another concern. Sometimes, leftover plastic is discarded. It’s not always recyclable. The process needs careful planning and accuracy. Mistakes can be costly, leading to lost time and resources. Understanding these factors is vital for successful implementations.

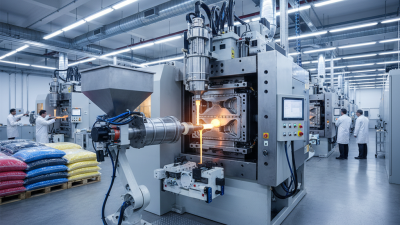

Common Applications and Industries Utilizing Injection Molding Techniques

Plastic injection molding is widely used across various industries. It produces parts with high precision and efficiency. Automotive, healthcare, and consumer goods heavily rely on this technique. In fact, the automotive sector alone accounts for nearly 28% of the global injection molding market. Components like dashboards, bumpers, and interior fittings are commonly manufactured through this process.

Consumer electronics also benefit significantly. Companies produce covers and housings for gadgets using injection molding. The lightweight and durable plastics help reduce costs and improve product longevity. According to industry reports, the market for consumer electronics is projected to grow by 5% annually, pushing further advancements in molding technology.

Tips: Consider the environmental impact when using plastics. Employing recycled materials in injection molding can mitigate waste. Always evaluate the design for manufacturability. A well-optimized design minimizes defects and reduces production costs. Remember that adjustments to tooling can lead to better results. Innovations in automation are paving the way for even more efficient production processes. Embrace the journey towards sustainability in the industry.

Related Posts

-

What is Low Cost Injection Molding and How it Revolutionizes Manufacturing Efficiency

-

Unlocking the Secrets of Low Cost Injection Molding: A Comprehensive Guide for Innovators

-

What is Plastic Injection Molding and How Does it Work

-

How to Choose the Right Injection Molding Tooling for Your Project

-

Top 10 Tips for Successful Injection Molding of Small Parts?

-

Top 10 Tips for the Injection Moulding Process Success?