Why Are Plastic Profiles the Best Choice for Your Construction Projects

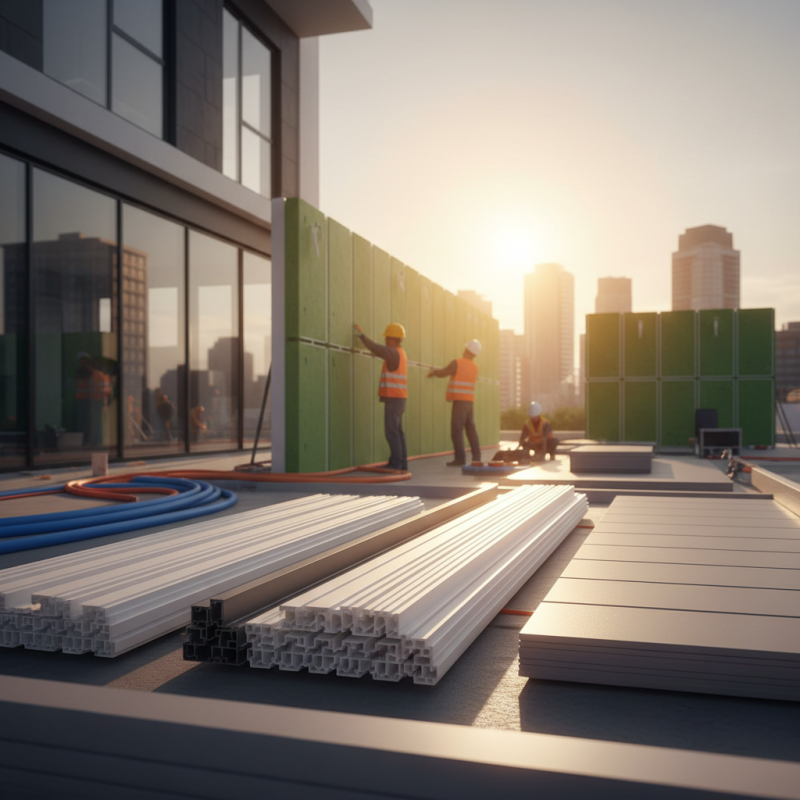

In the ever-evolving world of construction, choosing the right materials can significantly impact both the efficiency and sustainability of a project. Among the myriad of options available, plastic profiles have emerged as a top choice for modern construction endeavors. Their versatility, durability, and cost-effectiveness make them an ideal solution for various applications, ranging from framing and cladding to piping and insulation. With the growing emphasis on sustainable building practices, plastic profiles stand out not only for their performance but also for their reduced environmental footprint.

These innovative materials offer numerous advantages over traditional alternatives. For instance, plastic profiles are lightweight yet robust, facilitating ease of handling and installation, which can save valuable time and labor costs on-site. Furthermore, they exhibit excellent resistance to moisture, chemicals, and UV radiation, ensuring a longer lifespan and lower maintenance needs in comparison to wood or metal. As the construction industry increasingly seeks to balance functionality with environmental responsibility, integrating plastic profiles into projects can lead to smarter, more sustainable building solutions that meet the demands of today’s market.

Benefits of Using Plastic Profiles in Construction Projects

The use of plastic profiles in construction projects has gained significant traction in recent years, and it's easy to see why. One of the primary benefits of plastic profiles is their exceptional resistance to corrosion and degradation, which is crucial for longevity in various construction applications. According to a report by the Plastic Industry Association, the expected lifespan of plastic materials can exceed 50 years in outdoor applications, dramatically reducing the need for repairs and replacements over time. This durability is particularly advantageous in environments exposed to harsh weather conditions, which often compromise traditional building materials.

Moreover, plastic profiles offer significant energy efficiency benefits. Research from the U.S. Department of Energy indicates that plastic building materials can contribute to improved thermal insulation properties, leading to reduced energy consumption for heating and cooling. This can lower operational costs for buildings over time, making plastic profiles an economically attractive option for developers and builders alike. Additionally, the lightweight nature of plastic profiles simplifies transportation and installation, reducing labor costs and construction time. These factors combined make plastic profiles an increasingly preferred choice in the construction industry, providing a sustainable solution that aligns with modern environmental standards and practices.

Benefits of Using Plastic Profiles in Construction Projects

Durability and Longevity of Plastic Materials

When it comes to construction projects, the choice of materials significantly impacts the overall durability and longevity of structures. Plastic profiles stand out as one of the best options due to their remarkable resistance to various environmental factors. Unlike traditional materials, plastic profiles do not corrode, rust, or decay over time, making them an ideal choice for both indoor and outdoor applications. Exposure to moisture, UV rays, and extreme weather conditions will not compromise the structural integrity of plastic materials, ensuring they maintain their functionality and appearance for years to come.

Moreover, the manufacturing processes of plastic profiles allow for enhanced durability without sacrificing flexibility. They can withstand heavy loads and resist impacts, making them suitable for a wide range of construction applications, from window framing to structural supports. The longevity of plastic materials translates to reduced maintenance costs over time, as they require minimal upkeep compared to their metal or wooden counterparts. By investing in plastic profiles, construction projects can achieve both aesthetic appeal and long-term reliability.

Cost-Effectiveness Compared to Traditional Materials

When considering materials for construction projects, plastic profiles stand out for their cost-effectiveness compared to traditional materials. One of the primary advantages of plastic profiles is their lower manufacturing and installation costs. With the ability to produce them in various shapes and sizes using advanced techniques, plastic profiles often require less labor and time during installation. This efficiency translates into savings not only on materials but also on labor costs, making them an appealing choice for budget-conscious constructors.

In addition to reduced upfront costs, plastic profiles often exhibit longevity and durability that can lead to lower long-term expenses. Unlike wood or metal, which may require frequent maintenance or replacement due to weather conditions or corrosion, plastic profiles can withstand various environmental factors. Their resistance to moisture, UV rays, and pests reduces the need for costly upkeep, further enhancing their fiscal appeal. As a result, by opting for plastic over traditional materials, construction projects can achieve a balance between initial investment and overall lifecycle costs, ultimately ensuring a smarter use of financial resources.

Versatility and Design Flexibility of Plastic Profiles

Plastic profiles have emerged as a highly versatile option for various construction projects, offering unique advantages in design flexibility that traditional materials often cannot match. According to a report by the Global Plastic Profiles Market Analysis, the demand for plastic profiles has grown significantly, with an expected CAGR of 5.9% from 2021 to 2026. This growth is driven by the material's adaptability, allowing architects and builders to create intricate designs that cater to contemporary aesthetic demands while retaining superior functional characteristics.

One key aspect of plastic profiles is their ability to be molded into complex shapes and sizes without compromising structural integrity. This flexibility not only facilitates creative architectural solutions but also enables the integration of innovative features such as insulation and soundproofing. A study from the International Journal of Architectural Engineering highlighted that projects utilizing plastic profiles often experience a 20-30% reduction in installation time compared to traditional materials, due to their lightweight nature and ease of handling.

Moreover, the environmental benefits of plastic profiles cannot be overlooked. Many manufacturers are now producing profiles from recycled materials, contributing to sustainable construction practices. According to a report by the Resilient Infrastructure & Environment Group, buildings designed with sustainable materials, including plastic profiles, can achieve up to 30% energy savings in long-term operational costs. This combination of versatility, design flexibility, and sustainability makes plastic profiles an increasingly attractive choice for modern construction projects.

Environmental Impact and Sustainability of Plastic in Construction

The environmental impact of construction materials is becoming increasingly critical as the industry seeks sustainable solutions. Plastic profiles, in particular, offer a compelling case for eco-friendliness. According to a report by the International Energy Agency (IEA), the production of plastic emits significantly lower greenhouse gases compared to traditional materials like steel and concrete. For instance, studies show that the carbon footprint of plastic used in construction can be as much as 70% lower than that of steel, making it a much more sustainable choice.

Additionally, the lifecycle assessment of plastic materials reveals their potential for recycling and reuse. The European Commission’s Circular Economy Action Plan highlights that recycled plastics can reduce raw material demand by around 30%. This aligns with the industry's drive towards a circular economy, where materials are continuously repurposed. Furthermore, utilizing plastic profiles can result in less waste during both manufacturing and installation processes, with reports indicating a 50% reduction in material waste compared to more traditional construction methods.

Incorporating plastic profiles into construction projects not only addresses the pressing issue of sustainability but also contributes to energy efficiency. A study from the National Renewable Energy Laboratory indicates that buildings constructed using plastic materials can achieve better thermal insulation, thereby reducing energy consumption for heating and cooling by up to 25%. As the construction sector continues to evolve, the emphasis on environmentally friendly materials like plastic profiles will play a pivotal role in mitigating climate change and promoting responsible building practices.

Why Are Plastic Profiles the Best Choice for Your Construction Projects - Environmental Impact and Sustainability of Plastic in Construction

| Dimension | Plastic Profiles | Traditional Materials |

|---|---|---|

| Weight | Lightweight | Heavy |

| Recyclability | High (up to 100%) | Lower (depends on type) |

| Durability | Excellent (resistant to corrosion) | Variable (subject to rusting) |

| Energy Savings during Production | Lower energy consumption | Higher energy consumption |

| Insulation Properties | Good thermal insulation | Variable |

| Environmental Impact | Lower carbon footprint | Higher carbon footprint |

Related Posts

-

Ultimate Checklist for Selecting the Right Plastic Profiles for Your Projects

-

Exploring the Versatility and Applications of Plastic Profiles in Modern Design

-

How to Select the Right Plastic Profiles for Your Next Project

-

How to Choose the Right PVC Film for Your Packaging Needs

-

Exploring the Versatility and Applications of PVC Film in Modern Industries

-

2025 Top PVC Material Innovations for Sustainable Construction and Design