Revolutionizing Manufacturing: The Future of Plastic Injection Molding Technologies

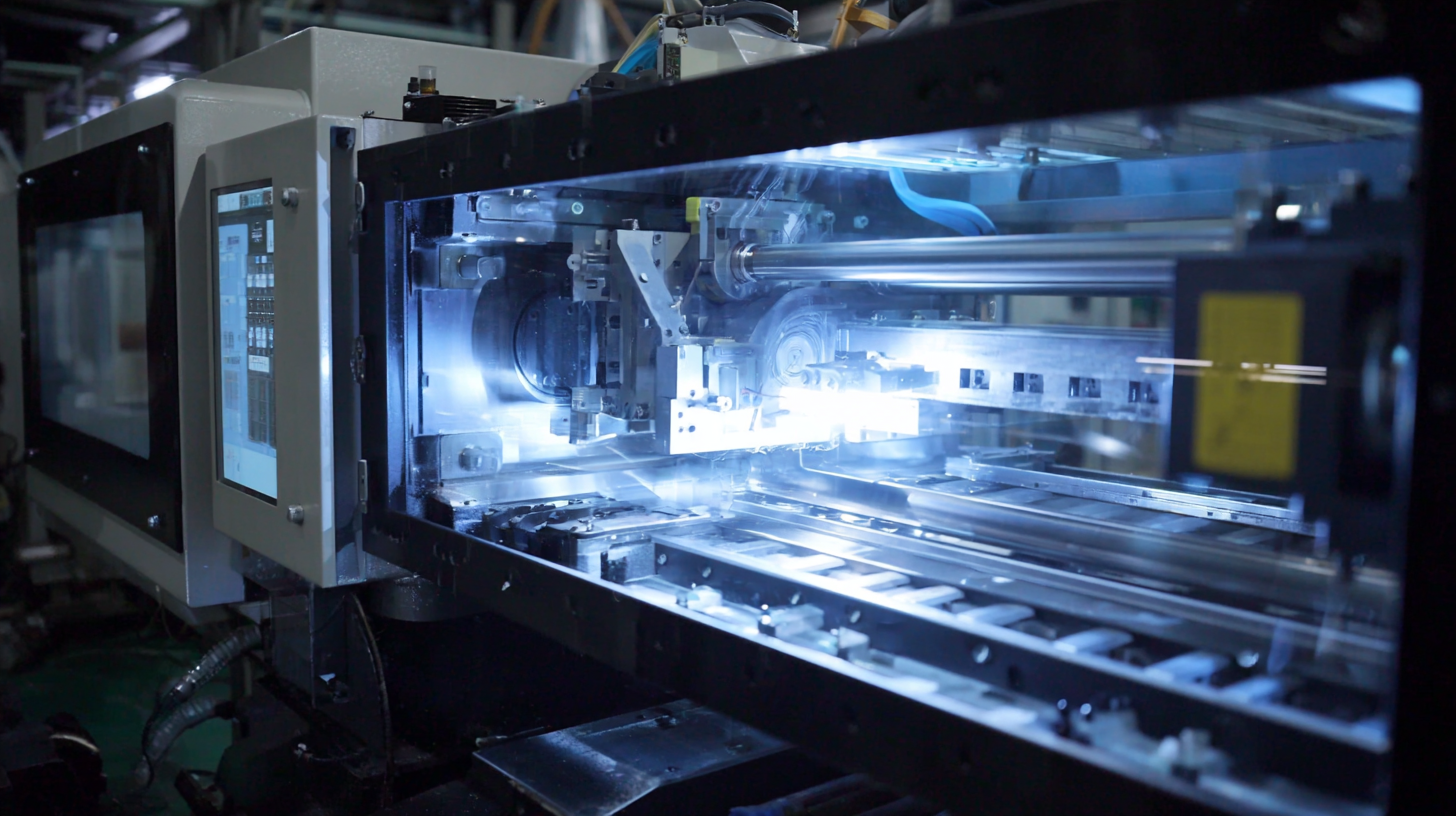

The landscape of manufacturing is undergoing a transformative shift, driven by rapid advancements in technology and innovative processes. Among these, plastic injection molding stands out as a pivotal method that is revolutionizing production capabilities. This technique, which involves injecting molten plastic into molds to create high-precision components, is not only increasing efficiency but also expanding design possibilities. As industries evolve, the future of plastic injection molding promises to embrace automation, sustainable practices, and enhanced material properties, making it an essential focus for manufacturers aiming to stay competitive.

In this exploration, we will delve into the reasons behind the surge in plastic injection technology, examining how it meets the demands of modern product design and production standards while paving the way for a more sustainable future.

Exploring Advanced Materials in Plastic Injection Molding for Enhanced Performance

The evolution of plastic injection molding technologies is significantly influenced by the adoption of advanced materials that enhance performance and versatility. In recent years, the introduction of innovative polymers and composite materials has expanded design possibilities, allowing for the production of complex geometries with greater precision and reduced waste. These materials not only improve the mechanical properties of the final products but also enable manufacturers to cater to specific industry requirements, such as lightweight components for automotive applications or high-temperature resistance for electronic devices.

Moreover, the integration of smart materials into the injection molding process is paving the way for new functionalities in manufactured products. For instance, materials that can change color or shape in response to environmental stimuli are becoming increasingly viable. This capability empowers designers to create adaptive solutions that meet dynamic consumer needs. The shift towards sustainable materials, such as biodegradable polymers, is also gaining traction, as manufacturers aim to reduce their environmental footprint while maintaining performance standards. These advancements herald a new era in plastic injection molding, marked by enhanced efficiency, sustainability, and innovation.

Maximizing Efficiency: Integrating Automation in Injection Molding Processes

The integration of automation in plastic injection molding processes is set to revolutionize manufacturing, significantly enhancing efficiency and productivity. Advanced automation technologies, such as robotics and artificial intelligence, streamline various stages of the injection molding cycle. By automating repetitive tasks, manufacturers can reduce cycle times, minimize human error, and improve output consistency. These advancements not only optimize production flow but also allow for real-time monitoring and adjustments, which lead to better quality control and reduced waste.

Moreover, the synergy between automation and modern manufacturing techniques enhances flexibility in production. Automated systems can quickly adapt to changes in design specifications or production volumes, making it easier for companies to respond to market demands. This adaptability is crucial in an era where customization and rapid prototyping are increasingly valued. By embracing these automated solutions, manufacturers can not only maximize their operational efficiency but also position themselves competitively for future challenges in the industry, paving the way for a more sustainable and innovative manufacturing landscape.

Revolutionizing Manufacturing: The Future of Plastic Injection Molding Technologies

| Technology Type | Efficiency Gain (%) | Typical Lead Time (Days) | Cost Reduction (%) | Automation Level |

|---|---|---|---|---|

| Robotic Arm Integration | 30 | 15 | 25 | High |

| Smart Mold Technology | 25 | 20 | 20 | Medium |

| Machine Learning Optimization | 40 | 10 | 30 | High |

| Real-time Monitoring Systems | 20 | 12 | 15 | Medium |

| Predictive Maintenance | 35 | 18 | 28 | High |

Innovative Design Techniques to Optimize Mold Creation and Production

The future of plastic injection molding technologies is being significantly shaped by innovative design techniques that optimize mold creation and production. As digital factories become a prevalent model for smart manufacturing, industries are harnessing advanced digital simulation and virtual reality technologies. This allows for comprehensive planning and optimization of the production processes, enhancing efficiency and reducing time-to-market for new products. According to industry reports, the global automotive tooling (molds) market, valued at approximately $41.32 billion in 2024, is anticipated to grow to $60.88 billion by 2033, with a compound annual growth rate (CAGR) of about 4.4%.

Moreover, the focus on innovation as a key driver of development reflects the commitment of companies to embrace technological advancements. By constructing robust frameworks for innovation, manufacturers are not only improving their operational capabilities but also ensuring that they remain competitive in a rapidly evolving market. The ongoing optimization of design methodologies in mold creation is set to play a crucial role in meeting the complex demands of high-quality, efficient manufacturing processes. As new solutions are implemented, they can lead to significant gains in productivity and product quality across the industry.

Sustainability Practices: Reducing Waste in Plastic Injection Molding Operations

In the quest for more sustainable manufacturing practices, the plastic injection molding industry is increasingly focusing on reducing waste and improving efficiency. According to a report by Allied Market Research, the global plastic injection molding market is projected to reach $400 billion by 2027, which underscores the industry's significant impact on resource consumption. Implementing sustainability practices in this sector can help mitigate environmental concerns while also enhancing profitability. Innovative technologies, such as closed-loop systems, have proven effective, enabling manufacturers to recycle scrap materials back into the production cycle.

Moreover, adopting advanced analytics and real-time monitoring can play a pivotal role in minimizing waste during the molding process. Studies from the Boston Consulting Group indicate that adopting such technologies can reduce operational waste by up to 50%. Additionally, incorporating bioplastics and implementing energy-efficient machines can lower carbon emissions significantly, further aligning manufacturing practices with global sustainability goals. As the industry evolves, integrating these sustainability practices not only supports environmental stewardship but also strengthens the competitive edge of manufacturers in a rapidly changing market landscape.

Future Trends: Embracing Smart Technology for Predictive Maintenance in Molding Equipment

The manufacturing landscape is undergoing a dramatic transformation, particularly in the realm of plastic injection molding. As companies strive to optimize their operations, the integration of smart technology is emerging as a game-changer. Predictive maintenance, powered by advanced data analytics, is enabling manufacturers to foresee equipment failures before they occur, significantly reducing downtime and maintenance costs.

To implement effective predictive maintenance, manufacturers should focus on collecting real-time data from their molding machines. This involves utilizing IoT sensors that monitor various machine parameters such as temperature, pressure, and cycle times. By analyzing this data, businesses can identify patterns and anomalies that may signal potential issues.

Tips: Regular training for your maintenance team on data interpretation and equipment operation can enhance the effectiveness of predictive maintenance. Additionally, investing in software that offers predictive analytics capabilities will streamline the process and improve decision-making. Engaging with machine manufacturers for updates on technology can also provide insights into new features designed to enhance predictive maintenance strategies.

Related Posts

-

Exploring the Future of Injection Molding at the 138th Canton Fair 2025: Industry Insights and Growth Projections

-

Injection Moulding Process Challenges That Every Global Buyer Should Know

-

How to Optimize PVC Injection Molding for Maximum Efficiency and Quality

-

How to Choose the Right Injection Molding Materials for Your Project Success

-

Unveiling the Advantages of Polypropylene Plastic: A Game Changer for Modern Manufacturing

-

How to Optimize Your Process for Polypropylene Injection Molding Success