Revolutionizing Product Design with Innovative PVC Injection Molding Techniques

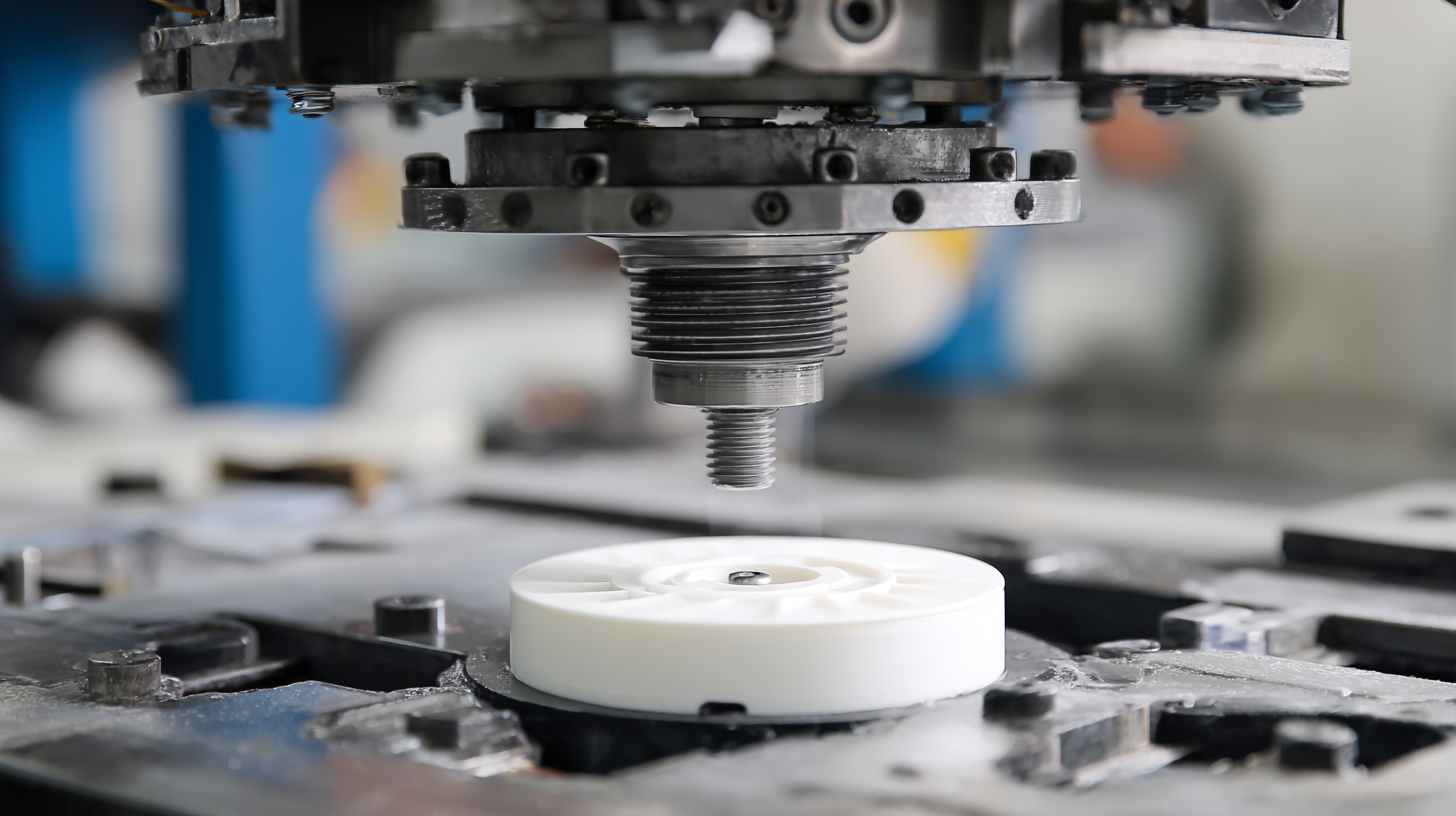

In the ever-evolving landscape of product design, the integration of innovative techniques has become paramount for manufacturers aiming to stay competitive. PVC injection molding stands at the forefront of this transformation, offering unparalleled precision and versatility in creating complex designs with efficiency and cost-effectiveness. This revolutionary method allows designers to explore new avenues in aesthetics and functionality, making it a game-changer in the industry.

By employing advanced PVC injection molding techniques, companies can not only enhance the durability and quality of their products but also significantly reduce production times and waste. In this guide, we will delve into the intricacies of PVC injection molding, exploring its benefits, applications, and best practices that can empower designers and manufacturers alike to push the boundaries of innovation in product design.

Whether you are a seasoned professional or a newcomer to the field, understanding these techniques can pave the way for a new era of creative possibilities.

Innovative Trends in PVC Injection Molding for Modern Product Design

The landscape of product design is experiencing a significant transformation due to innovative trends in PVC injection molding. This method, renowned for its efficiency and versatility, now sees advancements that enhance both aesthetic appeal and functional performance. Designers are increasingly adopting multi-material injection techniques that allow for varying textures and colors within a single part, enabling more intricate and visually appealing designs. This not only streamlines production processes but also reduces material waste, aligning with sustainability goals.

Moreover, the incorporation of smart technologies into PVC injection molding is paving the way for the creation of interactive products. By integrating sensors and connectivity features during the molding process, manufacturers can develop products that respond to user inputs or environmental conditions. This leap towards smarter product design emphasizes not only innovation in functionality but also consumer engagement, ultimately revolutionizing how users interact with everyday items. As these trends continue to evolve, the future of product design holds exciting possibilities fueled by cutting-edge PVC injection molding techniques.

Key Advantages of Advanced PVC Injection Techniques in Development

Advanced PVC injection molding techniques are transforming the landscape of product design by offering numerous advantages that streamline the development process. One key benefit is the significant reduction in production time. Traditional methods often involve lengthy setups and multiple stages, whereas modern approaches allow for quicker cycles, enabling companies to bring products to market faster. This efficiency is crucial in today’s competitive environment, where time-to-market can be a decisive factor in a product's success.

Moreover, innovative PVC injection techniques enhance the quality and consistency of the products being manufactured. With precise control over material flow and temperature, manufacturers can achieve impeccable finishes and intricate designs that were previously unattainable. This capability not only elevates the aesthetic appeal of the final products but also improves their durability. As a result, businesses are increasingly opting for advanced PVC molding methods to meet consumer demands for high-quality, reliable goods while minimizing waste and production costs.

Revolutionizing Product Design with Innovative PVC Injection Molding Techniques

| Key Advantages | Description | Impact on Development |

|---|---|---|

| Cost Efficiency | Lower raw material costs and reduced labor expenses make PVC injection molding economical. | Allows for competitive pricing of products in the market. |

| Design Flexibility | Complex shapes and intricate designs can be easily achieved. | Encourages creativity and innovation in product design. |

| Durability | PVC materials are resistant to impact, weather, and chemicals. | Increases the longevity of products, leading to higher customer satisfaction. |

| Speed of Production | Injection molding is a fast process, enabling rapid manufacturing. | Helps meet tight deadlines and increases market responsiveness. |

| Sustainability | Advancements in recycling technologies for PVC reduce environmental impact. | Aligns products with green initiatives, appealing to eco-conscious consumers. |

Exploring Customization and Flexibility in PVC Product Design

The landscape of product design has undergone a significant transformation with the advent of innovative PVC injection molding techniques. These methods not only enhance the manufacturing process but also provide unparalleled customization and flexibility. Designers can now create intricate shapes and unique textures that were once thought impossible, allowing for personalized products that cater to specific needs and preferences. This level of customization opens doors for businesses to differentiate themselves in a crowded market, appealing to niche audiences with tailored solutions.

Tips for successful PVC product design include thoroughly understanding the material properties and how they affect the molding process. Selecting the right grade of PVC for your specific application can significantly influence the final product's durability and aesthetic appeal. Moreover, collaborating closely with injection molding experts can refine design concepts and ensure that functional requirements are met while maintaining a high degree of customization.

Additionally, embracing modern design software tools can streamline the prototyping phase, enabling rapid iterations and adjustments in design before moving to production. This iterative approach not only saves time and resources but also enhances creativity, allowing designers to explore bold ideas and innovations in PVC products.

Sustainability Practices in PVC Injection Molding for Eco-friendly Products

The use of PVC injection molding in product design has seen a significant transformation, particularly with the increasing emphasis on sustainability. Manufacturers are now adopting eco-friendly practices that not only reduce waste but also minimize environmental impact. For instance, innovative recycling techniques have been integrated into the PVC processing stage, allowing for the reuse of scrap materials. This not only cuts down on the demand for virgin PVC but also promotes a circular economy within the industry.

Moreover, advancements in PVC formulations have led to the development of more sustainable materials that are free from harmful additives. These eco-friendly resins maintain high performance and durability while reducing toxicity. Additionally, companies are investing in energy-efficient machinery that lowers the carbon footprint during the production process. By marrying cutting-edge technology with sustainable practices, the PVC injection molding sector is leading the way in creating products that are as environmentally responsible as they are innovative.

Future-Proofing Product Design with Smart PVC Injection Technologies

The evolution of PVC injection molding techniques is profoundly impacting product design, pushing boundaries and introducing smarter solutions that not only enhance efficiency but also future-proof products. Recent studies from Research and Markets indicate that the global PVC market is projected to grow at a compound annual growth rate (CAGR) of 3.4% from 2022 to 2027, evidencing a strong shift towards advanced manufacturing processes. Companies are now leveraging innovative technologies such as 3D printing integration and intelligent automation to optimize their injection molding workflows. This strategic move ensures designs are not only aesthetically appealing but also functional and sustainable.

Tips for Future-Proofing Your Product Design:

- Embrace Automation: Implement smart machinery that utilizes IoT technology, enabling real-time monitoring and predictive maintenance which can reduce downtime.

- Focus on Sustainability: Select eco-friendly PVC materials that comply with international environmental standards, thereby meeting consumer demand for sustainable products.

- Invest in Prototyping: Utilize rapid prototyping techniques to test and refine designs swiftly, allowing for faster market release and adaptability to consumer feedback.

By adopting these strategies and staying informed about industry shifts, designers can harness the full potential of innovative PVC injection molding, setting a foundation for long-term success in an increasingly competitive landscape.

Related Posts

-

How to Optimize PVC Injection Molding for Maximum Efficiency and Quality

-

Envisioning Tomorrow: The Role of Polypropylene Plastic in Sustainable Manufacturing

-

Innovative Injection Moulding Process Examples That Drive Global Procurement Efficiency

-

Understanding Injection Molding Tooling Processes and Their Industry Impact

-

How to Optimize Your Process for Polypropylene Injection Molding Success

-

Exploring Trends in Injection Molding Materials at the 138th Canton Fair 2025