Discovering the Secrets of Low Cost Injection Molding for Beginners

In today's competitive manufacturing landscape, "low cost injection molding" has emerged as a game-changer for startups and small businesses looking to optimize their production processes without sacrificing quality. According to a report by Allied Market Research, the global injection molding market is projected to reach $391.3 billion by 2028, growing at a CAGR of 4.5%. This trend highlights the increasing accessibility of advanced molding technologies for beginners eager to enter the market. With the right insights and tips, even those with limited capital can leverage low-cost methodologies to create high-quality prototypes and products.

The secret lies in understanding the nuances of material selection, mold design, and production efficiency—all critical factors in minimizing costs while maximizing output. As we delve into the essential strategies for effective low-cost injection molding, aspiring manufacturers will gain the knowledge needed to thrive in this dynamic industry.

Understanding the Basics of Injection Molding for Beginners

Injection molding is a manufacturing process that involves injecting molten material into a mold to create a variety of parts and products. For beginners, understanding the basics of this efficient and cost-effective method is crucial. According to a report by Grand View Research, the global injection molding market is expected to reach $353.8 billion by 2027, emphasizing its importance in various industries, from automotive to consumer goods.

One of the key aspects of injection molding for beginners is mastering the types of materials used. Thermoplastics and thermosetting plastics are the most common. Thermoplastics can be molded multiple times, making them suitable for higher production volumes, while thermosetting plastics are more durable but can only be shaped once.

**Tips:** Beginners should start by exploring low-cost materials such as polypropylene and polyethylene, which not only provide excellent versatility but also keep production costs down. Additionally, investing in a simple injection molding machine can greatly reduce initial costs. Understanding the mold design is essential, as well; a well-designed mold minimizes production defects and lowers waste, which is crucial for maintaining cost-effectiveness in any project.

Understanding the Basics of Injection Molding Costs

This bar chart illustrates the estimated costs associated with different aspects of injection molding for beginners, highlighting the various components that contribute to overall production expenses.

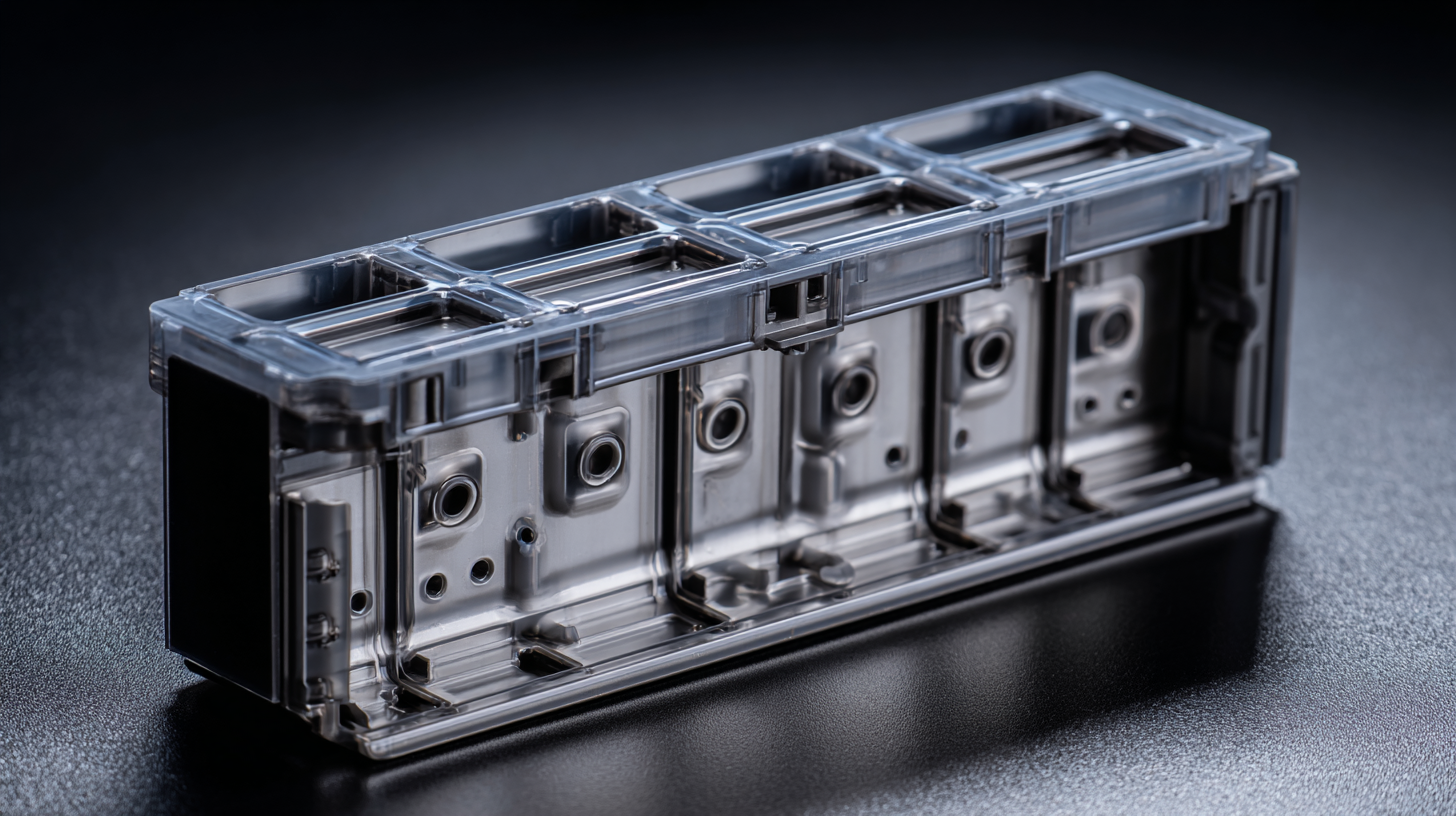

Essential Tools and Equipment for Affordable Injection Molding

When venturing into the world of affordable injection molding, having the right tools and equipment is essential for achieving high-quality results. A notable example of a simple injection mold can be created using advanced 3D printing technology with Rigid 10K resin. This material offers a sturdy and durable solution, perfect for prototyping and low-volume production. The resulting mold, produced by a professional 3D printer, showcases a good surface finish, which is crucial for ensuring that the final molded products have a polished appearance and fit together seamlessly.

In addition to the 3D printer, other tools and equipment necessary for beginners include a heating system for maintaining the right temperature during the injection process and a reliable injection machine for transferring melted materials into the mold. By utilizing these essential tools and materials, beginners can navigate the complexities of injection molding without incurring significant costs while still achieving impressive results in their projects.

Step-by-Step Guide to Setting Up Your Low-Cost Injection Molding Process

Setting up a low-cost injection molding process can seem daunting for beginners, but with a step-by-step approach, it becomes manageable.

First, begin by selecting the right equipment. Investigate affordable options such as used or smaller machines that fit within your budget while still meeting your production needs. Many manufacturers offer entry-level injection molding machines that can efficiently handle small runs and prototypes, making them ideal for startups and hobbyists.

First, begin by selecting the right equipment. Investigate affordable options such as used or smaller machines that fit within your budget while still meeting your production needs. Many manufacturers offer entry-level injection molding machines that can efficiently handle small runs and prototypes, making them ideal for startups and hobbyists.

Once you have secured your machinery, the next step is material selection. Research various thermoplastics that offer a balance of cost and performance for your intended application. Materials like polyethylene and polystyrene are affordable and widely used, making them great for initial projects.

Additionally, familiarize yourself with the mold making process. Consider using simple molds, possibly created from aluminum or 3D-printed designs, to minimize your costs while getting accustomed to the injection molding process. This practical approach not only helps in learning but also in ensuring quality production without excessive expenditure.

Common Mistakes to Avoid in Budget-Friendly Injection Molding

When venturing into low-cost injection molding, beginners often make critical mistakes that can impact the quality of their products and budget management. One common error is underestimating the importance of material selection. According to industry reports, the choice of resin significantly influences the final product's durability and functionality. Low-cost materials might save money upfront but can lead to increased scrap rates and product failures, ultimately resulting in higher long-term costs.

Another frequent misstep involves the design of the mold itself. Many newcomers overlook the complexities of mold design, thinking simpler shapes will suffice. However, innovative design techniques can facilitate better mold flow and cooling, ensuring a more efficient production process. A study by the American Society of Plastic Engineers found that optimized mold designs can reduce cycle times by up to 20%, demonstrating how a thoughtful approach can enhance productivity and reduce costs in the long run. By avoiding these pitfalls, beginners can navigate the challenging landscape of budget-friendly injection molding more effectively.

Discovering the Secrets of Low Cost Injection Molding for Beginners - Common Mistakes to Avoid in Budget-Friendly Injection Molding

| Mistake | Description | Consequence | Prevention Tips |

|---|---|---|---|

| Ignoring Design Constraints | Not considering the limitations of the molding process in product design. | Increased production costs and potential structural weaknesses. | Engage with a design engineer familiar with injection molding. |

| Underestimating Cost of Materials | Failing to accurately calculate the cost of resin and other materials. | Budget overruns leading to project delays. | Research and obtain multiple quotes for materials. |

| Neglecting Machine Maintenance | Skipping routine maintenance on injection molding machines. | Breakdowns resulting in costly downtimes. | Set a regular maintenance schedule and adhere to it. |

| Failing to Test Prototypes | Skipping prototype testing phase before mass production. | Potential design flaws leading to expensive recalls. | Conduct thorough testing on prototypes before production. |

| Overlooking Cooling Time | Not giving sufficient time for parts to cool and set. | Defects in molded parts such as warping or dimensional inaccuracies. | Optimize cooling times according to material specifications. |

Tips for Choosing the Right Materials for Low Cost Injection Molding

When embarking on low-cost injection molding, selecting the right materials is critical to ensure both efficiency and quality. For beginners, understanding the properties of various plastics is essential. Common choices include polypropylene, which is affordable and versatile, and ABS, known for its toughness. Each material has distinct characteristics that can affect moldability, strength, and finish, making it crucial to align the choice with the intended application and production volume.

Recent advancements in manufacturing technologies, such as 3D printing, have opened up opportunities for creating molds at lower costs. 3D-printed molds can accelerate the research and development process, enabling companies to adapt quickly to market demands while maintaining competitiveness. As beginners explore options for materials, they should consider not just the upfront cost but also the long-term implications on energy efficiency and sustainability, particularly with the growing trend of developing energy-saving injection molding machines.

Related Posts

-

What is Low Cost Injection Molding and How it Revolutionizes Manufacturing Efficiency

-

Innovative Injection Moulding Process Examples That Drive Global Procurement Efficiency

-

Injection Moulding Process Challenges That Every Global Buyer Should Know

-

Unlocking the Secrets of Low Cost Injection Molding: A Comprehensive Guide for Innovators

-

How to Choose the Right PVC Film for Your Packaging Needs

-

7 Essential Tips for Sourcing Plastic Parts Globally