How to Select the Right Plastic Profiles for Your Next Project

In the ever-evolving world of manufacturing and construction, the selection of the appropriate plastic profiles is critical for ensuring both functionality and sustainability in your projects. According to the latest industry report by MarketsandMarkets, the global plastic profiles market is projected to reach $45 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.4% from 2020. This growth is largely driven by the increasing demand for lightweight and durable materials across various sectors, including automotive, construction, and electronics. As professionals seek to enhance the performance of their applications while minimizing environmental impact, understanding the properties, types, and best use cases of plastic profiles becomes paramount. In this guide, we will delve into essential considerations that will enable you to choose the right plastic profiles for your next project, ensuring optimal results and innovation in your endeavors.

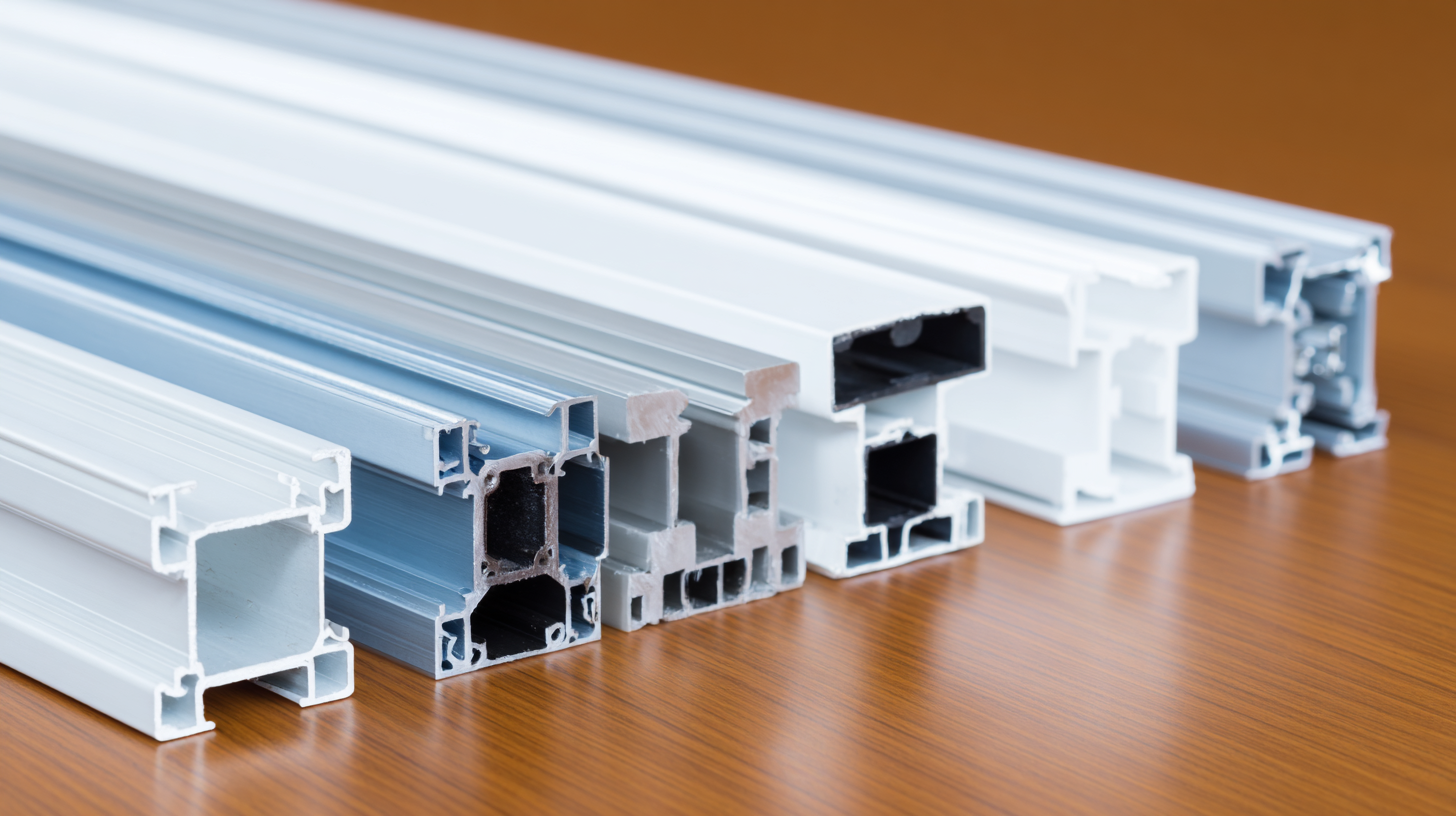

Understanding the Different Types of Plastic Profiles Available in the Market

When selecting the right plastic profiles for your project, it is essential to understand the various types available in the market. Plastic profiles are generally categorized based on their manufacturing process, application, and material properties. Profiles can vary in shapes, sizes, and functionalities, which makes them suitable for diverse applications in construction, packaging, automotive, and consumer goods. The choice of profile often hinges on the specific requirements of durability, flexibility, and resistance to environmental factors.

Currently, the global plastics extruded market is projected to grow significantly, reaching USD 259.21 billion by 2034. This growth reflects an increasing demand for specialized plastic profiles that cater to industry needs. However, the rising concern over plastic pollution emphasizes the importance of choosing materials that not only meet project specifications but also align with sustainability goals. Alternatives to conventional plastics, such as bioplastics and recycled materials, are gaining traction and may offer viable options for environmentally-conscious projects while still fulfilling performance criteria. Therefore, an informed selection process should consider both the material characteristics and the broader impact on the environment.

How to Select the Right Plastic Profiles for Your Next Project

| Type of Plastic Profile | Material | Applications | Properties |

|---|---|---|---|

| PVC Profiles | Polyvinyl Chloride | Windows, Doors, Fencing | Durable, Weather Resistant |

| Acrylic Profiles | Polymethyl Methacrylate | Display Cases, Signage | High Clarity, Lightweight |

| Polycarbonate Profiles | Polycarbonate | Roofing, Glazing | Impact Resistant, UV Stabilized |

| Nylon Profiles | Polyamide | Gears, Bearings | Low Friction, High Wear Resistance |

| Polypropylene Profiles | Polypropylene | Packaging, Automotive | Chemical Resistant, Lightweight |

Evaluating the Mechanical Properties of Plastic Profiles for Project Requirements

When selecting plastic profiles for your project, evaluating their mechanical properties is critical to ensuring performance and durability. Key properties such as tensile strength, impact resistance, and thermal stability can greatly influence the suitability of a plastic type for specific applications. For instance, according to a report by the Plastics Industry Association, materials like polycarbonate and polypropylene stand out in terms of impact resistance, with polycarbonate attaining a characteristic tensile strength of over 60 MPa. Such properties make them ideal choices for applications requiring enhanced durability, such as automotive components or safety equipment.

Additionally, the selection should consider the operating temperature range of the environment. High-performance plastics like polyetheretherketone (PEEK) exhibit exceptional thermal stability and can retain their mechanical properties in high-temperature applications, maintaining performance even at temperatures exceeding 250°C. The ASTM International's material testing standards provide reliable benchmarks for comparing these properties across different plastic profiles, allowing engineers to make informed decisions based on empirical data tailored to their project's specific requirements. Ultimately, a comprehensive understanding of these mechanical properties not only fosters the selection of the right material but also optimizes the overall functionality and lifespan of the project.

Assessing Environmental Considerations: Durability and Sustainability of Plastic Materials

When selecting plastic profiles for a project, environmental considerations are paramount. The durability and sustainability of plastic materials not only influence the performance of the final product but also its ecological impact. Recent studies emphasize the importance of adopting a circular economy approach, particularly in the context of healthcare plastics. This approach aims to minimize waste and optimize the lifecycle of materials, making it essential for manufacturers to consider the long-term implications of their storage and disposal methods.

Furthermore, applying life cycle assessment (LCA) methodologies can help quantify the environmental impacts of various plastic applications. For instance, using characterization factors to assess plastic pollution's impact on marine ecosystems underscores the need for accountability in material selection. Additionally, innovations like the utilization of recycled plastics in construction show promise in reducing landfill contributions while lowering production costs. Ultimately, integrating sustainability into the selection of plastic profiles can drive positive change by fostering resilience in both ecosystems and economies.

Cost Analysis: Balancing Quality and Budget When Selecting Plastic Profiles

When selecting plastic profiles for your next project, cost analysis plays a crucial role in balancing quality and budget. High-quality plastic profiles often come with a higher price tag, but they may offer better durability, longevity, and performance. Assessing the specific needs of your project can help you determine whether investing in more expensive materials is justified or if a more cost-effective option will suffice.

Tip 1: Create a budget outline based on your project needs and identify must-have features versus nice-to-have features. This will help you prioritize your spending, ensuring essential quality factors are not compromised while staying within your budget.

As you analyze costs, it's essential to consider the long-term value rather than just upfront expenses. Cheaper options may lead to increased maintenance or replacement costs down the line. Conduct thorough research and compare different suppliers to find the best balance between quality and affordability.

Tip 2: Look for suppliers that offer bulk purchasing discounts or special deals on high-volume orders. This can significantly help in reducing overall project costs while allowing you to maintain the quality you require.

Industry Standards and Certifications to Consider When Choosing Plastic Profiles

When selecting plastic profiles for your next project, understanding industry standards and certifications is crucial. According to a report by the Plastics Industry Association, over 60% of project failures can be attributed to non-compliance with established standards. The most recognized certifications include ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) standards, which ensure quality and performance. For instance, ASTM D638 outlines the tensile properties of plastics, allowing designers to ascertain the strength and flexibility of the materials they are considering.

Moreover, industry certifications such as UL (Underwriters Laboratories) and NSF (National Sanitation Foundation) offer additional assurance of safety and reliability. A survey by the American Chemistry Council noted that products with recognized certifications witness a 40% increase in market acceptance. Therefore, when choosing plastic profiles, it is not only necessary to evaluate the physical properties but also to ensure that the materials meet or exceed the relevant industry standards and certifications to guarantee the success and sustainability of your project.

Plastic Profile Selection Overview

Related Posts

-

Ultimate Checklist for Selecting the Right Plastic Profiles for Your Projects

-

Unlocking Efficiency: The Advantages of Utilizing Plastic Caps in Packaging Solutions

-

How to Choose the Right Plastic Coating for Your Manufacturing Needs

-

Innovative Injection Moulding Process Examples That Drive Global Procurement Efficiency

-

How to Optimize PVC Injection Molding for Maximum Efficiency and Quality

-

Unlocking the Advantages of Polyvinyl Chloride for Global Supply Chain Efficiency