Top 10 Tips for Successful Injection Molding of Small Parts?

The process of injection molding small parts has become increasingly vital in various industries. Reports indicate that the global market for injection molding is projected to reach $440 billion by 2025. In particular, small parts manufacturing plays a crucial role in sectors like automotive, aerospace, and consumer electronics. Effective techniques in this process can lead to improved precision and reduced waste.

Expert Anna Leong, a leading figure in the injection molding industry, states, “Mastering the nuances of injection molding small parts can greatly enhance product quality.” This highlights the importance of understanding intricate details during production. Many manufacturers tend to overlook factors like material selection and mold design, which can influence the end product's quality.

Challenges in this field can lead to significant setbacks. Designing molds for small parts often requires specialized knowledge and careful planning. Companies must adapt to evolving technologies and methodologies to remain competitive. As the demand for higher precision in injection molding small parts grows, professionals need to continuously reflect on their processes and embrace innovation.

Understanding the Basics of Injection Molding for Small Parts

Injection molding is a key process for producing small parts. Understanding the basics is essential for achieving successful results. This method involves injecting molten material into a mold to create precise components. For small parts, the accuracy of the mold design is crucial. Even slight imperfections can lead to defects in the final product.

Temperature control plays a significant role in the process. Maintaining the right temperature ensures proper flow and prevents defects. If the material cools too quickly, it may not fill the mold correctly. Conversely, if it’s too slow, material degradation can occur. The balance is delicate and requires constant monitoring.

Every project may present unique challenges. Sometimes molds might not perform as expected. Adjustments may be needed throughout the production run to optimize results. It's important to reflect on these experiences to improve future processes. This adaptability can make a difference in achieving quality parts consistently.

Top 10 Tips for Successful Injection Molding of Small Parts

Choosing the Right Materials for Small Part Production

Choosing the right materials for small part production is crucial. The material significantly impacts the durability and functionality of the final product. Engineers often face challenges in selecting the right polymers. Each material has unique properties that cater to specific applications.

Tip: Consider the part’s operating conditions. Will it face high temperatures or chemicals? Material selection should account for these factors. For example, polycarbonate offers great impact resistance, while nylon provides flexibility. Testing materials under real-world conditions can uncover unexpected weaknesses.

Another aspect to ponder is cost versus performance. Cheaper materials can seem appealing initially. However, they may not withstand the rigors of daily use. Unexpected failures often lead to higher long-term expenses. Thus, it's vital to balance between an economical choice and one that ensures reliability.

Tip: Prototype your designs with different materials. This allows you to evaluate their performance effectively. You might find that a more expensive option offers better longevity. In some cases, a lesser-known material might prove more suitable than established choices. Always be open to experimentation and learning from each trial.

Optimizing Machine Settings for Precision and Efficiency

Optimizing machine settings is crucial for the successful injection molding of small parts. Precision and efficiency directly affect production costs and part quality. According to a recent industry report, optimizing machine parameters can reduce cycle time by up to 30%. This means significant savings on overall production.

One tip to consider is maintaining consistent temperatures. Both melt and mold temperatures need to be carefully monitored. Variations can lead to defects in small parts. Another important aspect is injection speed. Adjusting the injection speed can minimize the risk of air entrapment and ensure good fill.

Maintaining equipment can be overlooked. Regular checks on the machine’s components can prevent breakdowns and delays. Additionally, communication among operators is essential. Misunderstandings can lead to equipment misuse and errors. It’s easy to assume everyone knows, but clarity is key for precision.

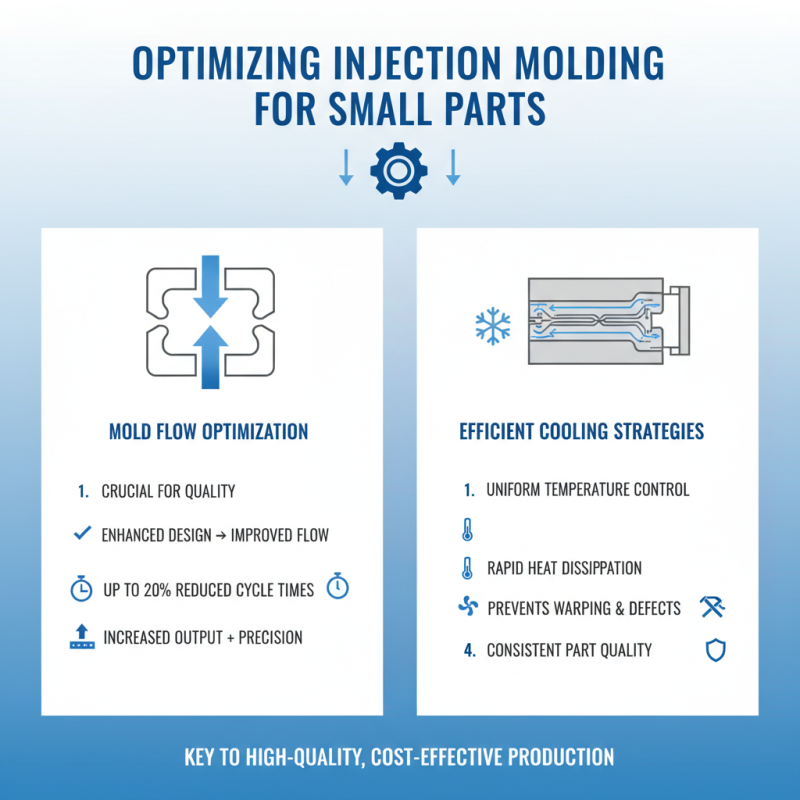

Design Considerations to Enhance Mold Flow and Cooling

In injection molding, mold flow and cooling are crucial for producing quality small parts. Proper design can enhance these processes significantly. According to industry reports, optimizing melt flow can reduce cycle times by up to 20%. This efficiency is vital for manufacturers aiming to increase output while maintaining precision.

Attention to gate design can improve flow characteristics. The size and location of gates impact how the plastic fills the mold. Miscalculations can lead to defects like short shots or warping. A well-placed gate minimizes pressure loss during injection. When parts are small, every millimeter counts.

Cooling channels must be considered early in the design phase. Uneven cooling leads to dimensional inaccuracies. Studies show that optimized cooling can cut cycle times by nearly 30%. Engineers should use simulations to visualize cooling patterns. Some designs face challenges in uniform heat dissipation. These issues can cause delays and added costs. Revising designs after production starts can be costly and time-consuming. Balancing flow and cooling design remains a critical yet often underestimated task in the injection molding process.

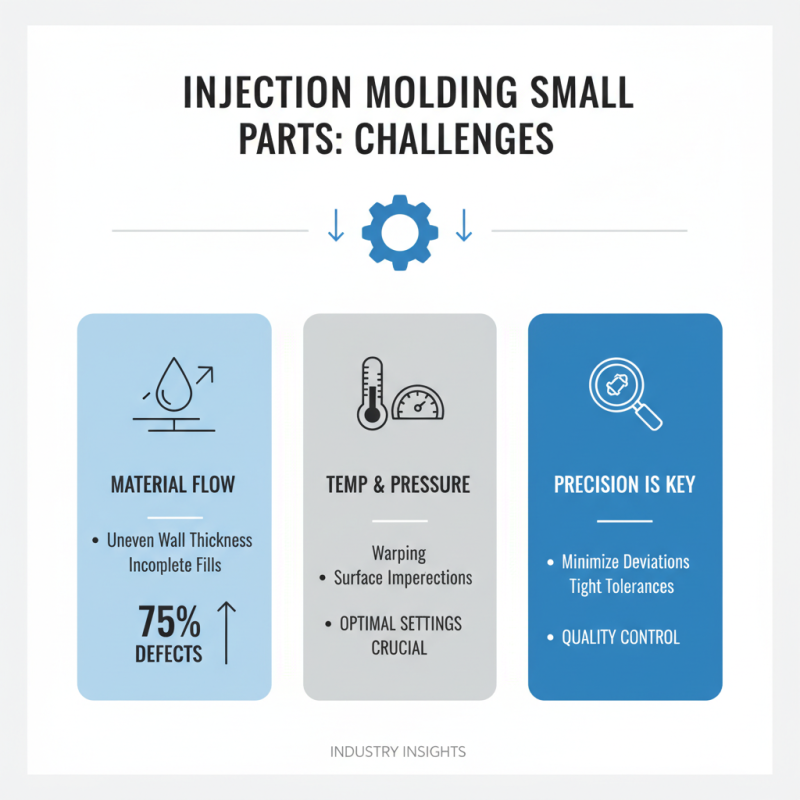

Common Challenges in Small Part Injection Molding and Solutions

Injection molding small parts presents unique challenges that professionals must navigate. Precision is key. According to industry reports, over 75% of defects in small parts arise from improper material flow. This can result in uneven wall thickness or incomplete fills. Maintaining optimal temperature and pressure settings is crucial. Deviations can lead to issues like warping or surface imperfections.

Another common challenge is the risk of contamination. Small parts are often sensitive to foreign materials. Any dust or residues can compromise the quality. A study showed that up to 20% of rejected parts were due to surface contamination. Implementing rigorous cleaning protocols and using dedicated equipment can mitigate these risks.

Shrinkage is yet another concern in small part injection molding. The smaller the part, the more pronounced the effects of shrinkage become. It can lead to misalignment and assembly issues. Controlling cooling rates and utilizing appropriate materials are essential strategies to address this. However, finding the right balance can be tricky. Testing and adjustments may be necessary to achieve desired outcomes.

Related Posts

-

Innovative Injection Moulding Process Examples That Drive Global Procurement Efficiency

-

Understanding Injection Molding Tooling Processes and Their Industry Impact

-

Injection Moulding Process Challenges That Every Global Buyer Should Know

-

Exploring the Future of Injection Molding at the 138th Canton Fair 2025: Industry Insights and Growth Projections

-

Top 10 Benefits of Injection Molding for Manufacturing Efficiency

-

10 Essential Tips for Designing Efficient Injection Molded Parts