2026 Top Plastic Molding Techniques to Boost Production Efficiency?

In the competitive world of plastic molding, efficiency is crucial. Experts agree that advancements in techniques can significantly impact production outcomes. John Smith, a renowned plastic molding specialist, states, “Optimizing production methods is the key to modern manufacturing success.” This highlights the continuous evolution of the industry.

The landscape of plastic molding is changing rapidly. Selecting the right techniques can mean the difference between success and setbacks. Techniques like injection molding, blow molding, and rotational molding offer various advantages. Each technique has its strengths and weaknesses, which is essential to consider. Some manufacturers face challenges in adapting to new technologies. It requires investment and training, posing a risk that may not pay off immediately.

Investing in the latest plastic molding techniques often provides long-term benefits. However, some companies hesitate due to costs and uncertainties. Experimentation may lead to unforeseen obstacles, urging professionals to rethink their approaches. Still, those willing to adapt can significantly enhance production efficiency. The journey toward optimization in plastic molding is fraught with challenges, but the potential rewards remain substantial.

Advancements in Plastic Molding Technologies for 2026

In 2026, the landscape of plastic molding technologies is set to evolve significantly. A recent industry report predicts a 20% increase in efficiency driven by new manufacturing techniques. Innovations like advanced injection molding and 3D printing are pivotal. They allow for complex designs with reduced waste. The industry must adapt to these changes, yet many manufacturers struggle with the transition.

As automation becomes integral, companies face challenges with workforce training. It's not easy to upskill a seasoned labor force accustomed to traditional methods. A study revealed that nearly 60% of businesses lack the resources to implement these advanced technologies effectively. This gap can hinder productivity and lead to missed opportunities.

Sustainability is another pressing concern. With around 30% of plastics ending up in landfills, pressure to innovate is immense. Companies are exploring bioplastics, which could represent a market growth of 25% by 2030. Yet, the development of these materials is complex. The journey toward sustainable plastic molding requires continuous investment in research and development. While advancements are promising, the industry must address these hurdles to fully harness the potential of new technologies.

Key Considerations for Boosting Production Efficiency in Molding

Increasing production efficiency in molding requires careful planning and execution. One key consideration is the choice of materials. Selecting the right plastic not only affects product quality but also impacts processing time. For instance, some plastics flow better under pressure, which can speed up the molding process. It's essential to test different materials and find the optimal balance between cost and performance.

Another aspect is the maintenance of molding equipment. Regular checks can prevent breakdowns that slow down production. However, many facilities overlook this crucial step. A small repair can often save considerable downtime. Implementing a routine maintenance schedule can minimize unexpected halts in production, but it requires discipline and attention to detail.

Additionally, training staff on new techniques can enhance efficiency. A well-trained workforce can adapt to new challenges more quickly. Investing in employee skills might seem tedious at first, but it pays off in the long run. Ultimately, improving production efficiency is an ongoing process that requires constant reflection and adjustment. Regularly revisiting these considerations can lead to significant improvements over time.

2026 Top Plastic Molding Techniques to Boost Production Efficiency

This chart illustrates the efficiency gains of various plastic molding techniques in 2026. The data showcases the percentage of efficiency improvement for each technique compared to traditional methods.

Comparative Analysis of Popular Plastic Molding Techniques

When it comes to plastic molding techniques, several methods stand out for their efficiency.

Injection molding is widely used in production. It allows for high-volume output and intricate designs.

However, the initial setup costs can be high. Companies must consider their production scale before committing to this technique.

Blow molding is another popular method. It excels in creating hollow parts, like bottles.

While the process is faster than injection molding, it has its limitations. The types of materials and shapes are restricted.

Moreover, quality control can be challenging.

Rotational molding is often overlooked but can be beneficial. It is ideal for large, hollow items and offers flexibility in design.

The cycle time is longer, which may deter some manufacturers. However, its waste reduction and lower machinery costs can make it an appealing option.

Understanding these nuances is vital for businesses aiming to enhance their production efficiency.

Sustainability Practices in Modern Plastic Molding Processes

Sustainability is a pressing concern in modern plastic molding processes. Many manufacturers are seeking greener practices. Recycling and reducing waste are essential for sustainability. However, not all methods are equally effective. Some companies struggle to find balance between production and eco-friendliness.

Using biodegradable materials is one approach. These materials can break down over time, reducing environmental impact. Yet, the cost can be a barrier. Not every company can afford the switch. Some still rely on traditional plastics due to lower expenses. This raises questions about long-term consequences.

Energy efficiency is another area for improvement. Innovations in molding technology can help reduce energy consumption. However, implementing these technologies requires investment. Companies often hesitate, fearing the initial costs. The challenge lies in convincing stakeholders of the benefits. Emphasizing the importance of sustainable practices can lead to meaningful change. Continuous reflection on current methods is crucial for progress.

Future Trends in Plastic Molding: Innovations and Predictions

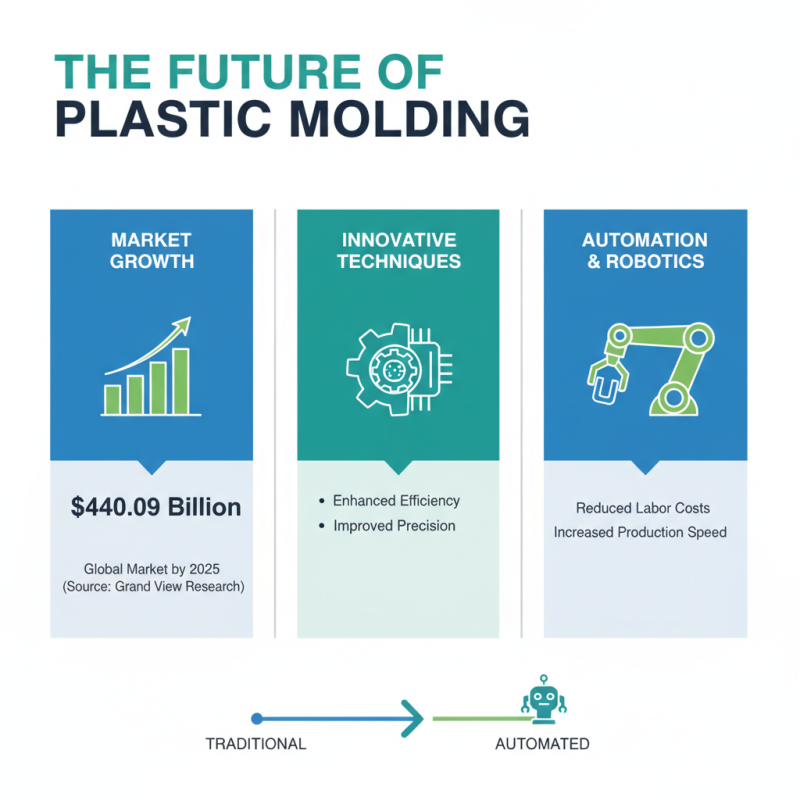

The future of plastic molding looks promising, driven by innovative techniques that enhance production efficiency. According to recent data from the Grand View Research report, the global plastic injection molding market is projected to reach $440.09 billion by 2025. Advancements in automation technology are changing the landscape significantly. Manufacturers are increasingly adopting robotics. This transition can reduce labor costs and improve precision.

Sustainability is another trend shaping the industry. The emphasis on using recycled materials is growing. A survey by the Plastics Industry Association found that over 70% of companies are investing in sustainable practices. However, the challenge lies in sourcing quality recycled materials. Not all recycled plastics perform well, which could affect the final product.

Additive manufacturing is gaining traction too. It allows for rapid prototyping and reduces waste. A report notes that 50% of industry players are considering this approach. Yet, implementation can be costly. Many companies struggle with scaling up their operations. Tapping into these innovations can drive significant improvements but requires careful planning and investment.

Related Posts

-

Exploring Trends in Injection Molding Materials at the 138th Canton Fair 2025

-

How to Choose the Right Injection Molding Materials for Your Project Success

-

Exploring the Versatility of PVC Plastic: Innovative Applications in Modern Design

-

2025 Top 10 Innovations in Injection Moulding Process: Boost Efficiency by 30%+

-

Top 10 Essential Injection Molding Tooling Techniques for Efficient Production

-

What is Poly Plastic and How it Revolutionizes Packaging Solutions in 2023