2025 Top PVC Material Innovations for Sustainable Construction and Design

In recent years, the construction and design industries have increasingly turned their focus towards sustainable practices, driven by the urgent need to minimize environmental impact. Among the various materials that have gained prominence in this movement, PVC material has emerged as a significant player due to its versatility, durability, and recyclability. As we look ahead to 2025, innovations in PVC material are set to reshape the landscape of sustainable construction and design, offering solutions that are both eco-friendly and efficient.

The upcoming advancements in PVC material are not just about enhancing functionality but also about integrating sustainability into every step of the production process. From improved recycling techniques to the development of bio-based additives, these innovations are designed to lessen carbon footprints and promote a circular economy within the industry. As architects and builders increasingly embrace these cutting-edge PVC solutions, the potential for creating spaces that harmoniously blend environmental responsibility with aesthetic appeal becomes more attainable than ever.

As we explore the top PVC material innovations of 2025, it is crucial to highlight their role in achieving sustainability goals while addressing the growing demand for resilient and high-performance building materials. This discussion will delve into the transformative properties of these innovations and how they can effectively contribute to greener construction practices, paving the way for a more sustainable future in design and architecture.

Recent Advances in PVC Materials for Sustainable Building Solutions

Recent advances in PVC materials have positioned them as pivotal components in sustainable building solutions. According to a 2023 report by the Global PVC Association, the use of PVC in construction provides significant environmental benefits, including up to a 60% reduction in energy use compared to traditional materials. These innovations are largely attributed to ongoing research into enhancing the lifecycle and recyclability of PVC, which is becoming increasingly important as the industry shifts towards greener practices. The implementation of new additives and processes has improved the performance of PVC, making it a strong contender in eco-friendly construction.

Moreover, sustainability in construction is being propelled by the emergence of bio-based PVC alternatives. A study by the International Association of Plastics Engineers indicated that bio-based PVC options could reduce carbon footprints by up to 30%, further aligning the material with contemporary sustainability goals. The development of these advanced materials not only supports energy-efficient practices but also addresses waste management issues, as advanced recycling techniques are enabling closed-loop systems. Currently, over 50% of PVC products in some markets are being recycled, reflecting a significant shift in how the industry views material reuse and waste reduction. This ongoing transformation underscores the pivotal role of PVC in meeting the rising demand for sustainable building solutions.

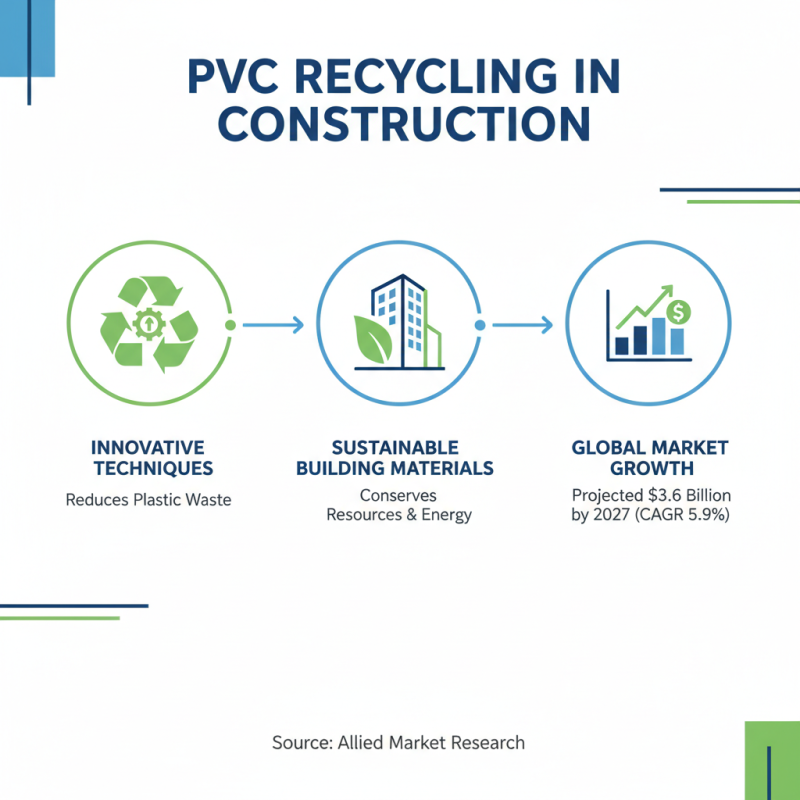

Innovative Recycling Techniques for PVC in Construction Applications

Innovative recycling techniques are revolutionizing the use of PVC in construction applications, aligning with the growing demand for sustainable building materials. According to a report by Allied Market Research, the global PVC recycling market is projected to reach $3.6 billion by 2027, registering a CAGR of 5.9% from 2020 to 2027. This increased focus on recycling not only reduces plastic waste but also conserves resources and energy in the production process.

One of the most promising innovations in PVC recycling is the development of advanced mechanical recycling methods that minimize material degradation. These techniques involve sorting, shredding, and processing used PVC products into high-quality recyclables that can be reintegrated into the manufacturing stream. In addition, the introduction of depolymerization processes allows for the breakdown of PVC into its fundamental monomers, enabling the creation of virgin-like quality materials. These methods have been shown to boost material recovery rates by up to 90%, enhancing the material's lifecycle and significantly reducing carbon emissions associated with new PVC production.

Furthermore, the integration of recycled PVC in construction not only contributes to circular economy practices but also meets increasing regulatory demands for sustainability. The European Union has set ambitious targets for plastic recycling, aiming for 50% of all plastic waste to be recycled by 2025. These advancements in recycling technology are crucial for helping the construction industry meet these targets while promoting energy-efficient and resource-conscious practices. With innovative techniques continuously emerging, the future of PVC in sustainable construction looks promising.

Biodegradable Alternatives to Traditional PVC for Eco-Friendly Design

The construction and design industries are increasingly recognizing the need for sustainable materials, leading to the rise of biodegradable alternatives to traditional PVC. According to a recent report by the Global PVC Sustainability Initiative, the demand for eco-friendly materials is expected to grow by over 25% by 2025 as more companies commit to reducing their carbon footprints. These biodegradable alternatives not only offer similar functional benefits as traditional PVC but also decompose naturally, minimizing environmental impact.

Innovative materials such as bio-based PVC, derived from renewable resources, and other biodegradable composites are becoming prominent in various applications, from flooring to wall coverings. A study from the International Journal of Sustainable Construction indicates that strategic use of these materials can reduce lifecycle greenhouse gas emissions by up to 40% compared to conventional PVC options. Adopting these sustainable materials enables architects and designers to create eco-friendly spaces without compromising on performance or aesthetic appeal.

**Tips:** When considering biodegradable options, assess material certifications to ensure they meet environmental standards. Additionally, collaborating with suppliers knowledgeable in sustainable practices can provide insights into the latest innovations in biodegradable materials. Finally, educating clients about the long-term benefits of these alternatives can facilitate a smoother transition toward sustainable design practices.

2025 Top PVC Material Innovations for Sustainable Construction and Design

The following chart illustrates the potential market share of biodegradable alternatives to traditional PVC materials in sustainable construction by 2025. The data represents various innovative materials and their projected adoption rates in the industry.

The Role of PVC in Reducing Carbon Footprint in Construction Projects

The construction industry is under increasing pressure to adopt sustainable practices, and PVC (polyvinyl chloride) is emerging as a vital material in this transition. According to a 2022 report by the European Commission, the use of PVC in construction contributes to energy efficiency both during installation and throughout the product's lifecycle. PVC products are known for their durability and low maintenance requirements, which can significantly lower the carbon footprint associated with construction and building operations. For instance, by utilizing PVC in windows and doors, construction projects can reduce energy consumption by up to 30%, effectively minimizing the operational carbon emissions over time.

Furthermore, the life cycle assessment (LCA) of PVC materials reveals that they have a lower overall environmental impact compared to many alternative materials. A report from the Vinyl Institute indicates that PVC production has advanced substantially in terms of energy usage and emissions. Innovations in manufacturing technologies have led to a reduction in greenhouse gas emissions by approximately 25% since 2000. This aligns with the global push towards the construction sector's goal of net-zero carbon buildings by 2050. Incorporating PVC in structural applications not only supports this target but also enhances the recyclability of materials, promoting a circular economy within the industry.

Case Studies: Successful Implementation of Sustainable PVC Innovations

In the realm of sustainable construction and design,

innovative applications of PVC materials are making significant strides,

showcasing their potential to reduce environmental impacts while maintaining aesthetic appeal and functionality.

One notable case study involves the use of advanced PVC cladding in a residential project that utilized recycled materials.

This innovative approach not only minimized waste but also enhanced energy efficiency through improved insulation properties,

demonstrating how sustainable practices can harmonize with contemporary design.

Another example can be found in the implementation of PVC-based flooring solutions in commercial spaces.

These floors were engineered with durability in mind, using additives that increase their lifespan while being

100% recyclable at the end of their use.

By opting for these sustainable PVC innovations, architects and designers successfully reduced the carbon footprint of their projects,

encouraging a shift toward environmentally responsible materials in commercial design.

Such implementations signify not only a trend but a commitment to creating a more sustainable future

through creative and responsible use of PVC in construction.

Related Posts

-

Exploring the Versatility of PVC Plastic: Innovative Applications in Modern Design

-

Exploring the Versatility of PVC Material: Applications, Benefits, and Environmental Impact

-

Top Strategies for Optimizing Plastic Angle Products in Your Business

-

How to Optimize Your Process for Polypropylene Injection Molding Success

-

What is Poly Plastic and How it Revolutionizes Packaging Solutions in 2023

-

How to Optimize Your Production Process with Poly Plastic Solutions