2026 Top Trends in Plastic Parts You Need to Know?

As we look towards 2026, the landscape of plastic parts is evolving rapidly. Experts predict that innovative designs and sustainable materials will shape the industry. John Stevens, a leading figure in the plastic manufacturing sector, emphasizes, "The future of plastic parts hinges on creativity and sustainability." This statement captures the essence of emerging trends that industry leaders are eagerly discussing.

In recent years, there has been a noticeable shift towards eco-friendly plastics. Many companies are exploring alternatives to traditional materials. This change isn’t just necessary; it also offers significant market opportunities. Businesses focusing on sustainable practices in plastic parts are gaining a competitive edge. Consumers are increasingly demanding environmentally responsible products, which is reshaping manufacturing strategies.

However, challenges remain. The transition to sustainable sources can be costly and complex. Moreover, maintaining product quality while innovating is a constant struggle. The path forward is not without obstacles. As we navigate these trends, it’s essential to reflect on the balance between innovation and responsibility in the plastic parts industry.

Emerging Materials: Innovations Driving the Future of Plastic Parts

The future of plastic parts is closely tied to innovations in materials. As industries evolve, new materials are emerging. These developments promise better durability and sustainability. Biodegradable plastics are gaining attention. They offer an eco-friendly alternative to traditional materials. This transition is not without challenges. The production processes can be complex and costly.

Recyclable composites are another game-changer. They can be reused, minimizing waste. However, integrating these materials into existing manufacturing techniques requires significant adjustments. Engineers must adapt to new properties and behaviors. Testing is crucial in this phase. The performance of these materials can vary widely. Balancing cost and functionality remains a persistent issue.

Furthermore, there’s a rise in smart plastics. These materials can respond to environmental changes. For instance, some can change color or shape. This functionality opens new design possibilities. Yet, the technology is still developing. Reliability in real-world applications is uncertain. Companies must invest in research to realize this potential fully.

2026 Top Trends in Plastic Parts You Need to Know

Sustainability Trends: Eco-Friendly Solutions in Plastic Manufacturing

Sustainability is reshaping plastic manufacturing. Eco-friendly solutions are gaining attention worldwide. Manufacturers are exploring bioplastics and recycled materials. These options reduce reliance on fossil fuels. However, challenges remain. Not all bioplastics are easily recyclable, and their production can still impact the environment.

Innovations in design can further support sustainability. Lightweighting techniques can help decrease raw material use. Yet, the industry must balance functionality and eco-friendliness. Many designs may not consider end-of-life disposal properly. Creating a closed-loop system is necessary for true sustainability.

Consumer demand for greener products continues to rise. Companies must find ways to meet these expectations. Environmental certifications and transparent supply chains are becoming crucial. As the market evolves, manufacturers must adapt. Striving for genuine innovation while addressing sustainable practices is no small feat.

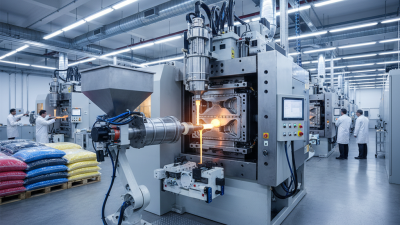

Smart Manufacturing: The Role of Automation in Plastic Production

In 2026, smart manufacturing will be crucial in plastic production. Automation is reshaping how products are manufactured. It streamlines processes and increases efficiency. Robotics are becoming more common on the factory floor. With precise movements, they reduce errors that often plague manual labor. This automation creates a more reliable output, but it also raises concerns about job displacement.

The integration of IoT devices enhances monitoring of production lines. Sensors gather real-time data to assess machine performance. This information allows manufacturers to predict maintenance needs, reducing downtime. However, these systems can be complex. Training operators to manage these technologies can be a challenge. Not every company is ready to adapt, which could lead to inconsistent productivity rates.

Additionally, while automation improves consistency, it may lack the creative touch of human oversight. Design modifications can require a nuanced understanding of materials. Automated systems may not always grasp subtle changes in design specifications. It’s crucial for manufacturers to find a balance between automation and human input. This dual approach could lead to more innovative solutions and better products overall.

2026 Top Trends in Plastic Parts You Need to Know

| Trend | Description | Impact on Manufacturing | Adoption Rate |

|---|---|---|---|

| Biodegradable Plastics | Increase in demand for eco-friendly alternatives to traditional plastics. | Improvement in brand image and compliance with regulations. | 30% |

| 3D Printing | Advanced additive manufacturing technology allows for rapid prototyping and customization. | Reduction in waste and increased design flexibility. | 50% |

| Smart Manufacturing | Integration of IoT and AI for automated production processes. | Enhanced efficiency and reduced manufacturing costs. | 40% |

| Recycled Plastics | Increasing use of recycled materials in production processes. | Minimization of environmental impact and conservation of resources. | 45% |

| Lightweight Materials | Shift towards lighter materials in automotive and aerospace industries. | Improved fuel efficiency and performance. | 35% |

Market Dynamics: Key Industries Shaping the Demand for Plastic Parts

The demand for plastic parts is driven by various key industries. Automotive, healthcare, and consumer goods are crucial sectors influencing this market. According to a recent report, the automotive industry alone accounted for 26% of the global plastic parts market in 2023. This trend is expected to grow, especially with the rise of electric vehicles that require lightweight components.

Healthcare is another major player. The demand for medical devices has surged, with analysts predicting a growth rate of 8.3% from 2024 to 2028. Plastic parts are essential in manufacturing syringes, containers, and other medical applications. However, the recycling of medical plastics remains a challenge. Many devices are single-use, leading to a significant waste issue.

Consumer goods are also shaping the plastic parts market. With e-commerce rising rapidly, packaging plays a crucial role. Approximately 40% of all plastic produced goes into packaging. Yet, many companies face criticism for their environmental impact. They must balance efficiency with sustainability. Industries should rethink their approach to achieve a more eco-friendly future.

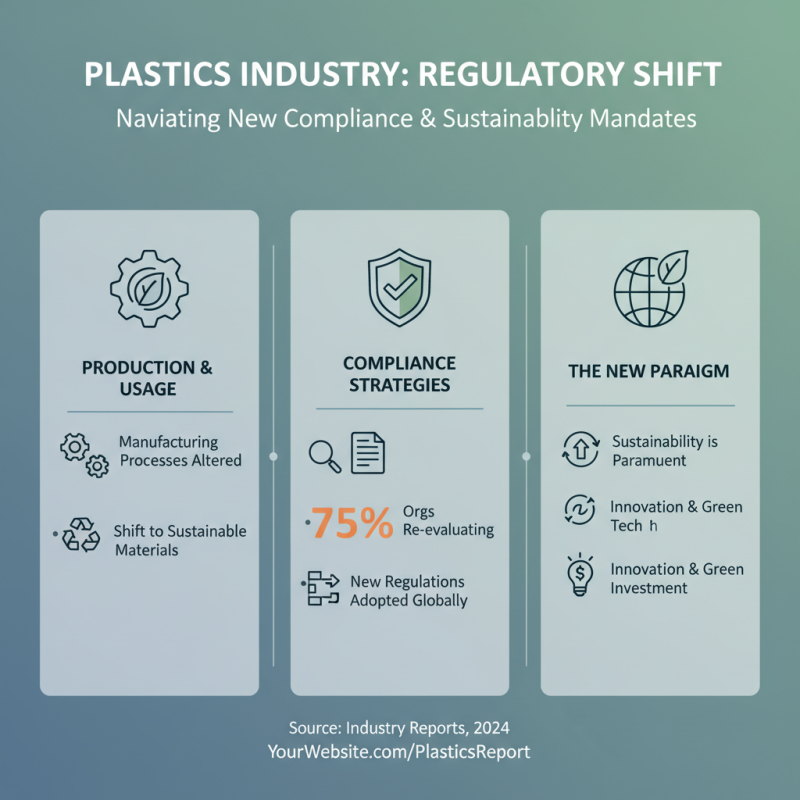

Regulatory Changes: Compliance and Standards Impacting Plastic Use

Regulatory changes greatly influence the plastic industry. These changes affect how manufacturers produce and use plastic parts. Recent reports highlight that nearly 75% of organizations are reevaluating their compliance strategies. This shift is crucial in a landscape where sustainability is paramount.

The European Union's tightened regulations push companies to adopt eco-friendly materials. In 2023, around 40% of businesses struggled to meet these new standards. This creates a disruptive market, where non-compliance can lead to fines or product recalls. As a result, many manufacturers are investing more in R&D. They aim to develop alternative materials to stay relevant and compliant.

Additionally, consumer awareness is rising. Surveys show 65% of consumers prefer brands that prioritize environmental impact. This pressure forces companies to rethink their long-term strategies. Some are even exploring bioplastics as substitutes. However, bioplastics often come with their own set of challenges. They can be more costly and less durable than traditional plastics. Balancing compliance, consumer demand, and cost-effectiveness remains complex.

Related Posts

-

7 Essential Tips for Sourcing Plastic Parts Globally

-

Discovering the Secrets of Low Cost Injection Molding for Beginners

-

What is Plastic Injection Molding and How Does it Work

-

Exploring the Future of Injection Molding at the 138th Canton Fair 2025: Industry Insights and Growth Projections

-

Exploring the Future of Plastic Angle Products at the 138th Canton Fair 2025 in China

-

Envisioning Tomorrow: The Role of Polypropylene Plastic in Sustainable Manufacturing