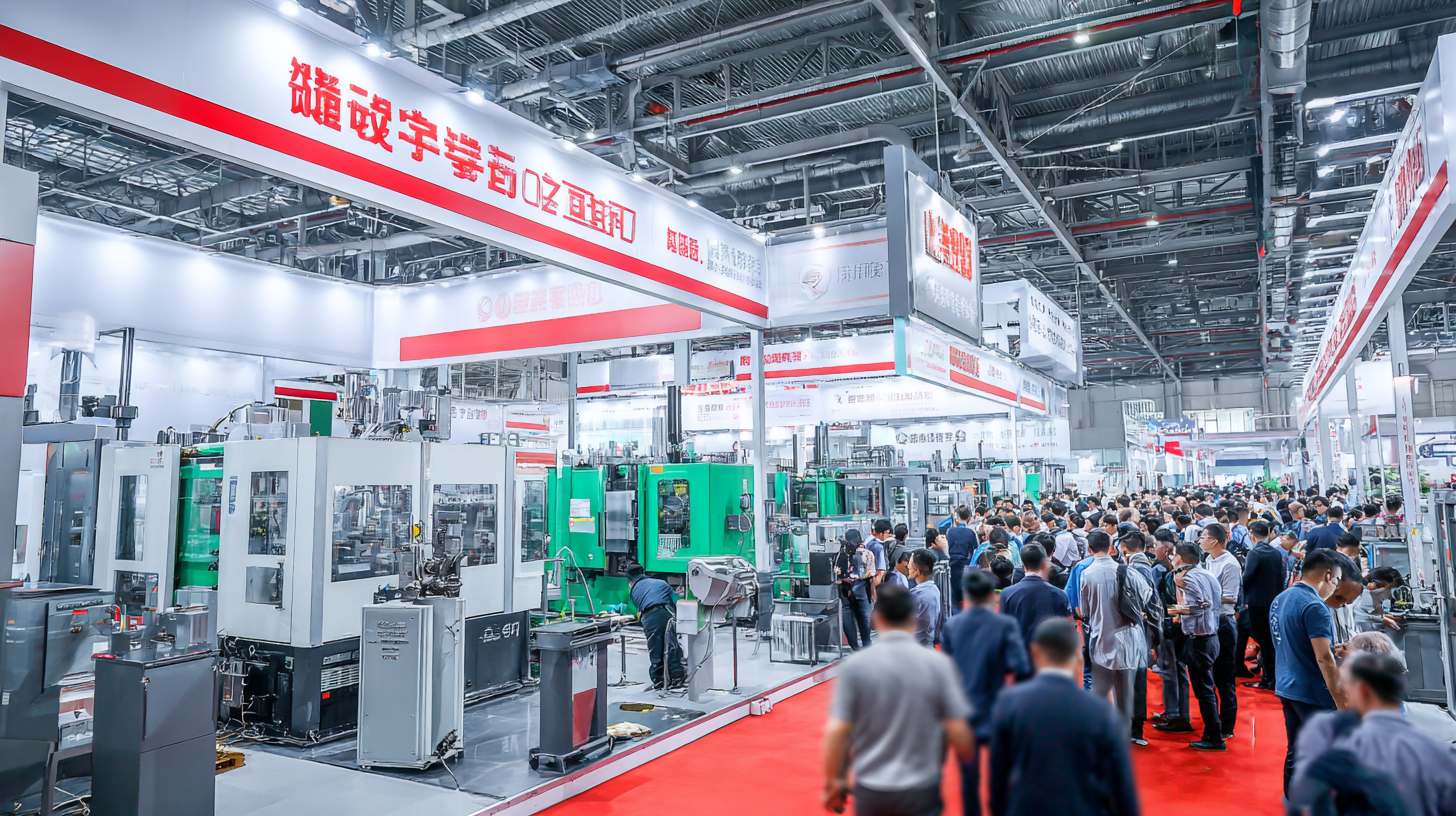

Exploring Trends in Injection Molding Materials at the 138th Canton Fair 2025

The 138th Canton Fair in 2025 serves as a pivotal platform for industry professionals to explore the latest trends in injection molding materials, a crucial segment of the manufacturing sector. Recent market analyses indicate that the global injection molding market is projected to reach approximately $350 billion by 2026, driven by increasing demand across various industries such as automotive, consumer goods, and healthcare. Moreover, advancements in technology and material science are enabling the development of high-performance injection molding materials, including biodegradable plastics and advanced composites, which offer enhanced durability and sustainability. As manufacturers seek innovative solutions to improve production efficiency and reduce environmental impact, the Canton Fair presents a unique opportunity for stakeholders to exchange knowledge and identify emerging trends that will shape the future of injection molding materials.

Current Innovations in Injection Molding Materials Showcased at the 138th Canton Fair

The 138th Canton Fair in 2025 highlighted significant innovations in injection molding materials, underlining the industry's ongoing evolution. As per the latest market research report by Mordor Intelligence, the global injection molding market is projected to reach USD 299.12 billion by 2027, growing at a CAGR of 4.83% from 2022. This surge emphasizes the shift towards advanced materials that enhance the efficiency and sustainability of manufacturing processes. Exhibitors showcased state-of-the-art thermoplastics and biodegradable materials, responding to the increasing demand for environmentally friendly solutions.

Among the noteworthy innovations were high-performance polymers and composite materials designed to withstand extreme conditions while maintaining lightweight properties. According to a report by Research and Markets, the demand for high-temperature resistant plastics is anticipated to grow significantly, driven by industries such as automotive and aerospace, where performance and durability are critical. At the fair, companies demonstrated how these cutting-edge materials not only improve product quality but also reduce cycle times, ultimately leading to cost savings and a reduced carbon footprint. The focus on sustainable practices and material efficiency reflected a broader trend across the manufacturing sector, positioning injection molding as a key player in the transition towards greener production methodologies.

Sustainable Solutions: Eco-friendly Materials in Injection Molding

At the 138th Canton Fair 2025, the spotlight is on sustainable solutions in the realm of injection molding materials. As environmentally conscious practices gain traction, manufacturers are increasingly investing in eco-friendly alternatives to traditional plastics. Biodegradable polymers, derived from renewable sources, are at the forefront of this shift, offering the potential to reduce waste and minimize the ecological footprint of production processes. These innovative materials not only fulfill performance expectations but also promote sustainability, aligning with global efforts towards a circular economy.

The shift towards sustainable injection molding materials is driven by both regulatory pressures and consumer demand for greener products. Exhibitors at the Canton Fair are showcasing a range of advanced materials that meet stringent environmental standards while maintaining high-quality performance. From bioplastics to recycled materials, companies are reinventing their product lines to incorporate sustainable choices, reflecting a commitment to reducing the industry's impact on the planet. This trend not only demonstrates the growing importance of environmental responsibility in manufacturing but also highlights the role of trade shows like the Canton Fair in fostering innovation and collaboration within the industry.

Emerging Trends in High-Performance Polymers and Composites

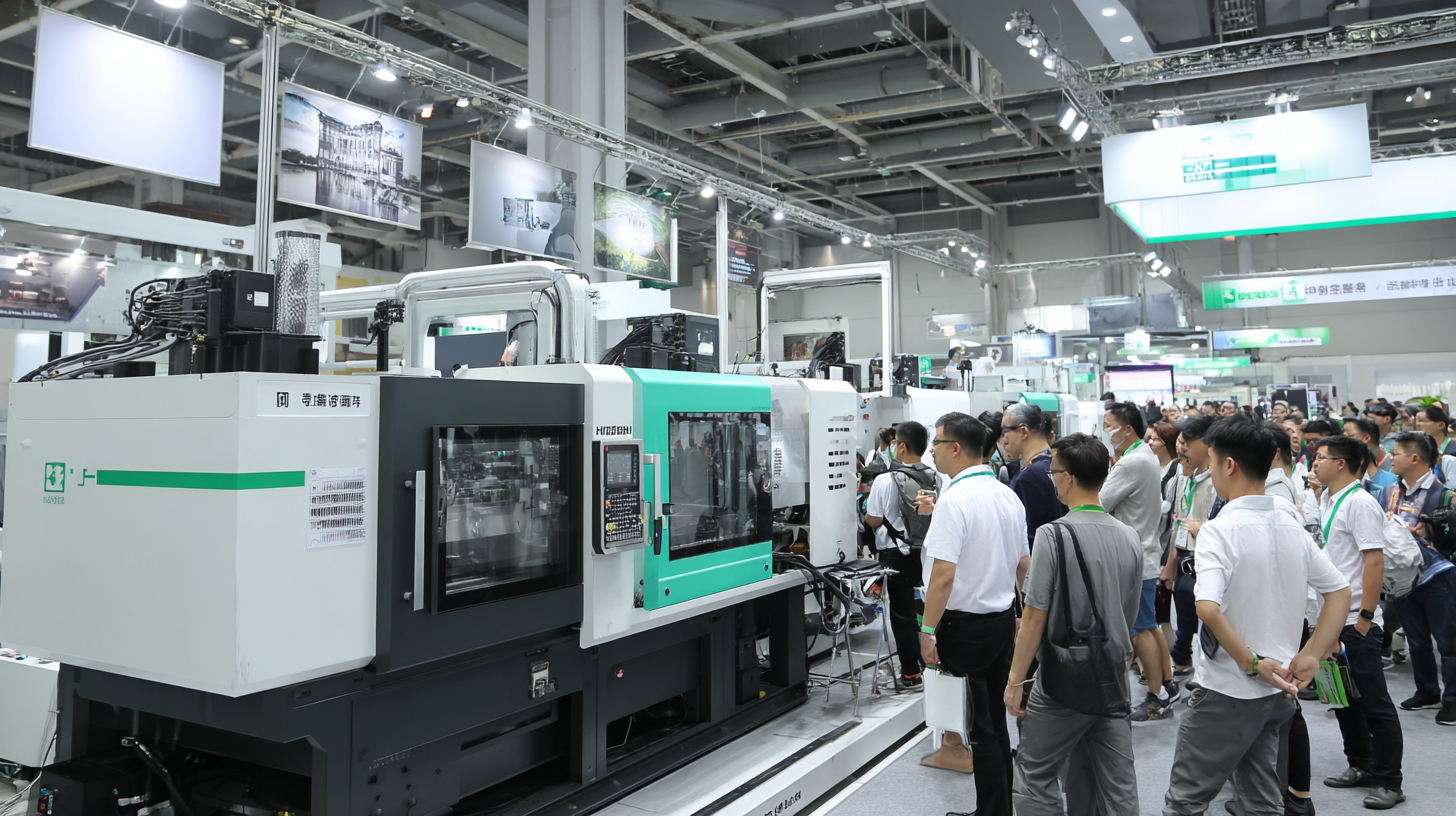

The 138th Canton Fair in 2025 promises to be a pivotal event for injection molding materials, particularly with a strong focus on emerging trends in high-performance polymers and composites. As manufacturers strive for enhanced durability and efficiency, the demand for advanced materials that can withstand extreme conditions is on the rise. Innovations in polymer science have led to the development of materials that not only exhibit superior mechanical properties but also offer significant weight reductions, making them ideal for various applications across industries such as automotive, aerospace, and consumer goods.

One of the standout trends is the increasing use of bio-based and recycled materials in injection molding. These sustainable alternatives not only reduce environmental impact but also meet the growing regulatory demands for greener manufacturing processes. Additionally, advancements in composite materials, such as carbon and glass fiber reinforced polymers, are enabling engineers to design products that combine lightweight characteristics with enhanced strength. The integration of smart materials that can respond to environmental stimuli further exemplifies the exciting directions this field is heading towards, showcasing the potential for customized solutions that cater to specific industrial needs.

Advancements in Technology for Enhanced Injection Molding Processes

The 138th Canton Fair in 2025 showcased a remarkable array of advancements in injection molding technology, emphasizing the industry's continuous evolution. One of the standout innovations was the integration of smart technology into the injection molding process. By leveraging Internet of Things (IoT) devices, manufacturers can now monitor production in real-time, leading to improved efficiency and reduced waste. This connectivity allows for predictive maintenance, anticipating machine failures before they occur and minimizing downtime.

Additionally, advancements in material science have introduced new polymer blends that enhance the properties of molded parts. For instance, bio-based materials and advanced composites are gaining traction, offering not only sustainability but also improved performance characteristics. These materials enable designers to create lighter, stronger products that meet stringent environmental standards while maintaining cost-effectiveness. As manufacturers continue to embrace these technological developments, the injection molding industry is poised for a transformative shift, highlighting the importance of innovation in staying competitive in the global market.

Exploring Trends in Injection Molding Materials at the 138th Canton Fair 2025 - Advancements in Technology for Enhanced Injection Molding Processes

| Material Type | Applications | Advancements | Sustainability | Cost (per kg) |

|---|---|---|---|---|

| Polypropylene (PP) | Packaging, Automotive Parts | Improved flow properties | Highly recyclable | $1.10 |

| Polycarbonate (PC) | Consumer Electronics, Medical Devices | Enhanced impact resistance | Limited recyclability | $2.50 |

| Acrylonitrile Butadiene Styrene (ABS) | Toys, Automotive Interiors | Lower emissions during processing | Recyclable options available | $1.70 |

| Engineering Plastics | Industrial Applications, Aerospace | Advanced thermal stability | Developing bio-based alternatives | $3.00 |

| Polyethylene Terephthalate (PET) | Bottles, Food Containers | Improved barrier properties | Widely recycled | $1.20 |

Market Insights: Demand and Growth Predictions for Injection Molding Materials

The injection molding materials market is poised for significant growth, driven by rising demand across various sectors, including automotive and packaging. In the global plastic packaging arena, the market is anticipated to expand from $454.9 billion in 2024 to a whopping $736 billion by 2032, showcasing the immense potential for injection molded products in creating efficient packaging solutions. This surge is primarily fueled by the increasing need for sustainable and innovative packaging methods that cater to consumer preferences.

Moreover, the automotive interior materials market is also on a robust growth trajectory, with projections indicating a notable increase due to the evolving demands for diverse materials, including composites and plastics. Notably, this market's shifts are driven by advancements in vehicle design and technology. As we look towards 2035, the diversity in applications ranging from dashboards to seating solutions will play a critical role in shaping the future of injection molding materials. With a CAGR of around 4.6% expected for polyethylene from 2025 to 2034, the market for injection molding continues to align itself with broader trends in sustainability and innovation, making it a key area for investment and development.

Related Posts

-

7 Compelling Reasons to Choose the Right Injection Molding Materials for Your Production Needs

-

Innovative Injection Moulding Process Examples That Drive Global Procurement Efficiency

-

How to Choose the Right Injection Molding Materials for Your Project Success

-

7 Reasons Why Polypropylene Injection Molding is the Best Choice for Your Project

-

How to Optimize PVC Injection Molding for Maximum Efficiency and Quality

-

Envisioning Tomorrow: The Role of Polypropylene Plastic in Sustainable Manufacturing