Exploring the Versatility and Applications of PVC Film in Modern Industries

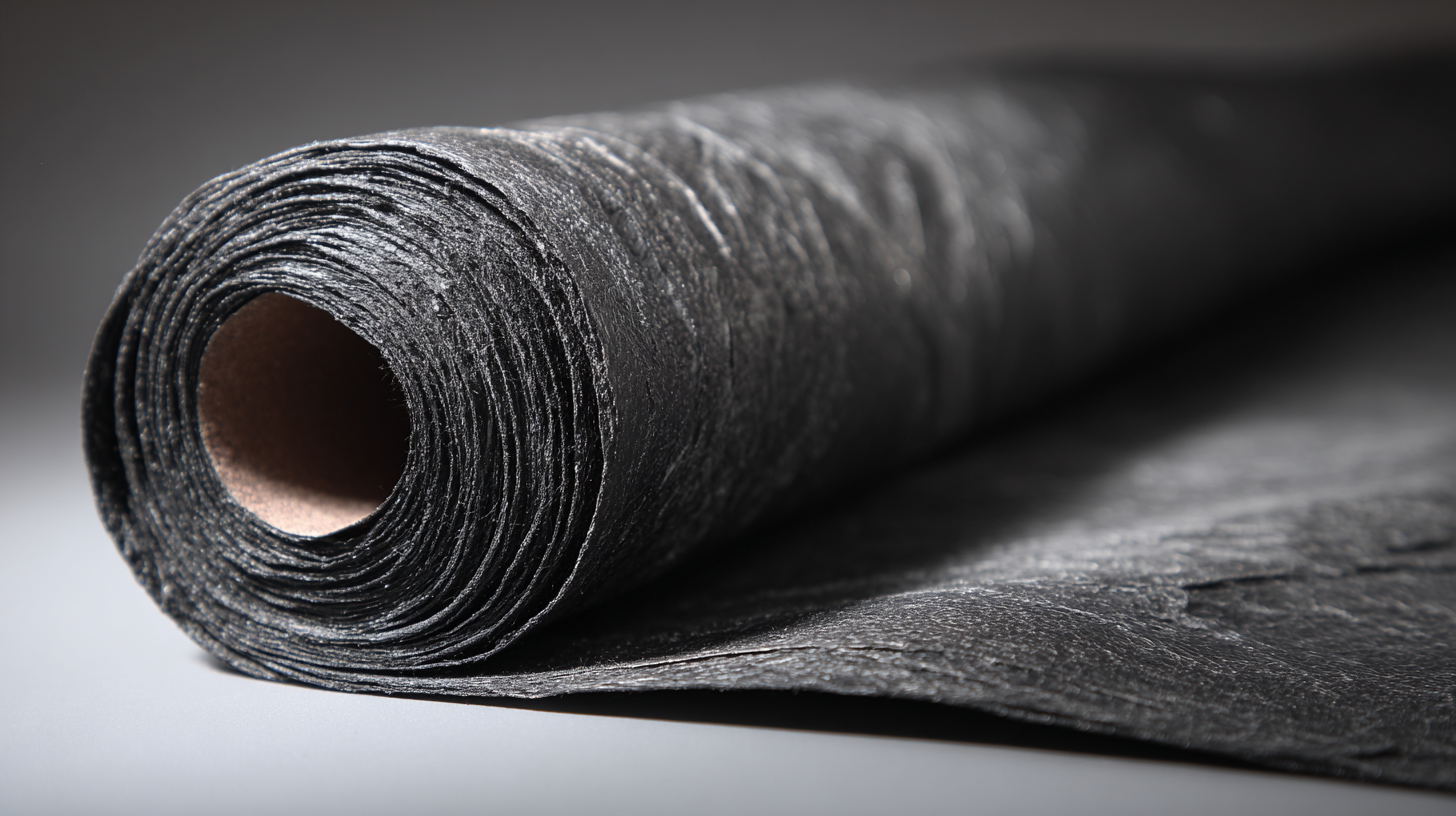

The versatility of PVC film has made it a cornerstone in various modern industries, as noted in the market analysis report by Global Industry Analysts, which projected the global PVC film market to reach USD 31.6 billion by 2026, growing at a CAGR of 5.2%. This remarkable adaptability stems from its unique properties, such as durability, flexibility, and resistance to chemicals and moisture, making it ideal for applications ranging from packaging materials to automotive interiors.

The versatility of PVC film has made it a cornerstone in various modern industries, as noted in the market analysis report by Global Industry Analysts, which projected the global PVC film market to reach USD 31.6 billion by 2026, growing at a CAGR of 5.2%. This remarkable adaptability stems from its unique properties, such as durability, flexibility, and resistance to chemicals and moisture, making it ideal for applications ranging from packaging materials to automotive interiors.

The packaging sector, in particular, has witnessed significant growth, with PVC film accounting for a substantial share due to its ability to preserve products while enhancing shelf appeal. Furthermore, innovations in manufacturing techniques are continuously broadening the scope of applications for PVC film, which now includes medical supplies, building materials, and even electronic components. This exploration delves into the multifaceted uses of PVC film, highlighting its indispensable role in contemporary industrial practices and future developments.

How to Choose the Right PVC Film for Your Specific Application

When selecting the right PVC film for specific applications, several critical factors must be considered to ensure optimal performance and versatility. First, the thickness and flexibility of the PVC film play a significant role; thicker films offer enhanced durability, while thinner films are more suitable for applications requiring flexibility, such as packaging or lamination. Additionally, the intended use of the film—whether for medical, food packaging, or industrial purposes—will dictate the necessary specifications, including barrier properties, resistance to chemicals, and regulatory compliance.

Moreover, understanding the environmental impact and sustainability of PVC films is becoming increasingly important. With the growing shift towards eco-friendly materials, industries are seeking PVC films that can meet both performance standards and environmental regulations. For example, sourcing films that are easily recyclable or produced using sustainable practices can enhance the overall appeal of a product. Therefore, assessing the specific needs of each application alongside the sustainability aspect can guide users in making informed decisions when selecting PVC films.

How to Properly Handle and Store PVC Film to Ensure Quality

Proper handling and storage of PVC film is critical to maintaining its quality and functionality in various applications across modern industries. According to a report from Smithers Pira, the global demand for PVC film is projected to reach approximately 3.5 million tons by 2025, emphasizing the importance of quality preservation. To ensure the longevity of PVC film, it should be stored in a cool, dry environment away from direct sunlight, as UV exposure can lead to degradation of the material. Additionally, maintaining a stable temperature and humidity level is crucial; ideal conditions generally hover around 15-25°C with a humidity level of 40-60%.

Proper handling and storage of PVC film is critical to maintaining its quality and functionality in various applications across modern industries. According to a report from Smithers Pira, the global demand for PVC film is projected to reach approximately 3.5 million tons by 2025, emphasizing the importance of quality preservation. To ensure the longevity of PVC film, it should be stored in a cool, dry environment away from direct sunlight, as UV exposure can lead to degradation of the material. Additionally, maintaining a stable temperature and humidity level is crucial; ideal conditions generally hover around 15-25°C with a humidity level of 40-60%.

It is also essential to handle PVC film with care to avoid physical damage. The film should be stored flat or rolled correctly to prevent creases and distortions that could affect its performance. According to a study by Technavio, improper storage and handling can lead to significant losses, with faulty materials leading to production downtime and increased costs for manufacturing industries. By following proper storage guidelines and handling practices, businesses can enhance the durability and efficiency of PVC film, maximizing its versatility and applications across numerous sectors, including packaging, construction, and automotive industries.

How to Optimize PVC Film Production Processes for Efficiency

The production processes of PVC film can be optimized to enhance efficiency and reduce waste, driving down costs while maintaining product quality. One approach is to invest in advanced machinery that can ensure precise control over temperature and pressure settings during the extrusion process. This not only improves the consistency of the film but also minimizes the chances of defects that can lead to additional material costs.

Tips: Regular maintenance of production equipment is crucial. Implement a routine check-up schedule to identify and rectify any potential issues before they escalate into costly downtimes.

Another method to enhance efficiency is to streamline the supply chain. Collaborating closely with raw material suppliers can result in better procurement practices, such as bulk buying, which lowers material costs. Additionally, implementing lean manufacturing principles helps in identifying waste within the production cycle, allowing for the refinement of processes that boost overall productivity.

Tips: Encourage staff training and development to cultivate a culture of continuous improvement, enabling employees to contribute ideas that can lead to significant process enhancements.

How to Evaluate the Environmental Impact of PVC Film Use

When evaluating the environmental impact of PVC film, it is crucial to consider its lifecycle, from production to disposal. According to a report by the European Commission, the production of PVC emits approximately 1.3 tons of CO2 per ton of material, which raises concerns about greenhouse gas contributions. Furthermore, the extraction of raw materials, predominantly derived from fossil fuels, poses significant environmental risks, including habitat destruction and pollution.

Another critical aspect to assess is the end-of-life phase of PVC film. Studies show that around 30% of PVC materials are incinerated, resulting in the release of dioxins and other hazardous substances if not properly managed. In contrast, only 14% of PVC waste is recycled, as reported by the PVC Industry Council, which highlights the need for improved recycling technologies and better regulatory frameworks to enhance sustainability. Addressing these challenges is essential for minimizing the environmental footprint of PVC film while recognizing its widespread applications across various industries, such as packaging and construction.

Exploring the Versatility and Applications of PVC Film in Modern Industries - How to Evaluate the Environmental Impact of PVC Film Use

| Application Area | PVC Film Type | Advantages | Environmental Impact | Recyclability |

|---|---|---|---|---|

| Packaging | Flexible PVC Film | High clarity, moisture resistance | Can release harmful chemicals if not disposed of properly | Partially recyclable; depends on local facilities |

| Construction | Rigid PVC Film | Durability, weather resistance | Long lifespan but significant embodied carbon | Recyclable, but often disposed of as waste |

| Medical | Medical-grade PVC Film | Biocompatibility, sterility | Safe for approved use, but disposal poses challenges | Limited recyclability, primarily incinerated |

| Automotive | PVC Coated Films | Scratch resistance, aesthetic appeal | Non-biodegradable, potential leaching of chemicals | Can be recycled, but often not collected |

| Signage | Vinyl PVC Film | Weatherproof, vibrant colors | Durable but contributes to plastic pollution | Recyclability varies; often discarded as trash |

How to Innovate with PVC Film in Emerging Industry Trends

PVC film is rapidly evolving, adapting to meet the demands of various emerging industries. Its versatility lends itself to innovative applications across packaging, construction, and automotive sectors. By enhancing the intrinsic properties of PVC—like durability, flexibility, and resistance to moisture—industries can innovate products that not only meet functional requirements but also appeal to aesthetic preferences.

For instance, in the packaging industry, companies are now exploring custom textures and colors in PVC films, making their products stand out while ensuring sustainability by using recyclable materials.

PVC film is rapidly evolving, adapting to meet the demands of various emerging industries. Its versatility lends itself to innovative applications across packaging, construction, and automotive sectors. By enhancing the intrinsic properties of PVC—like durability, flexibility, and resistance to moisture—industries can innovate products that not only meet functional requirements but also appeal to aesthetic preferences.

For instance, in the packaging industry, companies are now exploring custom textures and colors in PVC films, making their products stand out while ensuring sustainability by using recyclable materials.

Furthermore, as the trend for smart technologies grows, integrating electronics with PVC film offers exciting possibilities. Conductive inks and embedded sensors can be incorporated into PVC film to create interactive surfaces for electronics, revolutionizing how consumers engage with products. This integration not only adds value but also opens up avenues for smart packaging that can communicate with consumers, providing real-time information about freshness and usage. Embracing these trends will require collaboration between material scientists, designers, and industry leaders to push the boundaries of what PVC film can achieve in the modern landscape.

Related Posts

-

Unlocking the Secrets of Low Cost Injection Molding: A Comprehensive Guide for Innovators

-

How to Safely Recycle PVC Plastic: A Step-by-Step Guide for Sustainable Practices

-

Envisioning Tomorrow: The Role of Polypropylene Plastic in Sustainable Manufacturing

-

How to Choose the Right Injection Molding Materials for Your Project Success

-

7 Reasons Why Polypropylene Injection Molding is the Best Choice for Your Project

-

Unlocking the Advantages of Polyvinyl Chloride for Global Supply Chain Efficiency