Top 10 Benefits of Injection Molding for Manufacturing Efficiency

Injection molding has revolutionized the manufacturing landscape, offering unparalleled efficiency and precision in producing a wide variety of components. As industries strive to meet the ever-increasing demand for high-quality products, understanding the benefits of injection molding becomes crucial. This versatile technique not only streamlines production processes but also enhances product design flexibility, significantly reducing time to market.

One of the most compelling advantages of injection molding lies in its ability to produce complex geometries and tight tolerances with minimal waste. Manufacturers can leverage this technology to create intricate parts that would be difficult, if not impossible, to achieve through traditional manufacturing methods. Furthermore, the scalable nature of injection molding allows for high-volume production, making it an attractive option for businesses looking to optimize their workflow and reduce per-unit costs.

In this article, we will delve into the top ten benefits of injection molding that contribute to improved manufacturing efficiency. From reduced cycle times to enhanced material utilization, understanding these advantages will empower manufacturers to make informed decisions that drive competitiveness and innovation in their respective fields.

Advantages of Injection Molding in Streamlining Manufacturing Processes

Injection molding stands out as a pivotal technique in modern manufacturing, primarily due to its ability to streamline production processes. One significant advantage is the high level of precision it offers. The process enables manufacturers to produce complex shapes with tight tolerances, which minimizes the need for secondary operations and significantly reduces production time. Additionally, the repeatability of injection molding ensures consistent quality across large production runs. This reliability not only enhances product uniformity but also minimizes material waste, contributing to overall manufacturing efficiency.

Moreover, injection molding supports rapid scaling of production. With the capability to quickly switch molds, manufacturers can respond to market demands swiftly and adjust their output volumes without extensive downtime. This flexibility is particularly beneficial in industries where time-to-market is critical. The automation potential in injection molding further amplifies efficiency, as machines can operate continuously with minimal human intervention, optimizing labor costs and further enhancing productivity. By integrating these advantages, injection molding proves to be a crucial component in achieving streamlined manufacturing processes.

Enhancing Production Speed with Injection Molding Techniques

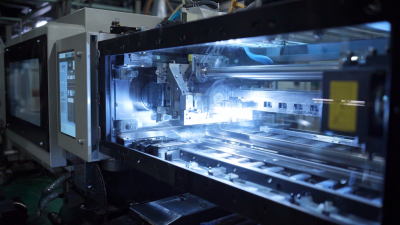

Injection molding is a game changer in the manufacturing industry, particularly when it comes to enhancing production speed. This technique allows for the rapid creation of complex parts and products through a highly automated process. The efficiency of injection molding stems from its ability to produce large quantities of items in a short timeframe. Once the molds are developed, they can be used repeatedly, drastically reducing the cycle time between productions. This not only increases throughput but also ensures consistency in product quality, a crucial factor for industries that rely on precision.

Moreover, injection molding techniques allow manufacturers to optimize their operations by integrating advanced technologies, such as computer numerical control (CNC) and robotic automation. These technologies help streamline the manufacturing process, allowing for quick changes in production runs without significant downtime. The versatility of materials used in injection molding enhances production speed as well; manufacturers can choose from a wide range of plastics and composites to meet specific requirements. As a result, companies can respond swiftly to market demands while maintaining high efficiency and reducing labor costs, thereby solidifying their competitive edge in the industry.

Top 10 Benefits of Injection Molding for Manufacturing Efficiency

This chart illustrates the top 10 benefits of injection molding techniques in enhancing manufacturing efficiency.

Cost Efficiency: How Injection Molding Reduces Overall Manufacturing Expenses

Injection molding stands out as a leading manufacturing process, primarily due to its cost efficiency. By utilizing multi-cavity molding techniques, manufacturers can significantly enhance production output while minimizing per-unit production costs. Recent insights indicate that the thermoplastic micro molding market is experiencing robust growth, reflecting the increasing demand for miniaturized components, particularly in the medical sector. This trend illustrates a shift towards high-precision manufacturing, where the initial investment in advanced molding technology is offset by the long-term savings generated through reduced waste and increased efficiency.

Tips: To maximize the benefits of injection molding, consider investing in advanced machinery that incorporates automation and connectivity features. These technologies not only streamline the manufacturing process but also enhance precision, ultimately leading to significant cost savings. Additionally, conducting a thorough analysis of the initial material costs versus long-term performance can help in making informed decisions that contribute to overall cost efficiency.

Moreover, as highlighted in industry reports, exploring options like metamaterial-based injection molding can lead to cost-effective solutions that cater to evolving market demands. Emphasizing sustainability through efficient manufacturing practices is not just a trend but a necessary shift that can lead to substantial operational savings.

Top 10 Benefits of Injection Molding for Manufacturing Efficiency - Cost Efficiency: How Injection Molding Reduces Overall Manufacturing Expenses

| Benefit | Description | Estimated Cost Savings (%) |

|---|---|---|

| High Production Efficiency | Injection molding allows for high-volume production with minimal delays. | 30% |

| Reduced Material Waste | The process creates fewer scraps compared to other manufacturing processes. | 20% |

| Shorter Production Cycles | Cycle times are quicker, enabling faster time-to-market. | 25% |

| Consistency in Quality | Injection molding provides uniformity in product quality. | 15% |

| Lower Labor Costs | Automation in molding minimizes manual intervention. | 18% |

| Complex Geometries | Allows for intricate designs that might be difficult to produce with other methods. | 10% |

| Material Versatility | Supports a range of materials, reducing the need for multiple processes. | 12% |

| Energy Efficiency | Modern machines use energy-efficient technologies, lowering costs. | 22% |

| Reduced Lead Times | Quick setup and turnaround capabilities lessen waiting times for customers. | 27% |

| Customizability | Easily accommodates changes in design, allowing for tailored production runs. | 14% |

Improving Product Consistency through Advanced Injection Molding

Advanced injection molding techniques play a crucial role in enhancing product consistency within the manufacturing process. The precision of injection molding allows for uniform distribution of materials, leading to minimal variation in product dimensions and properties. This consistency is vital for industries that demand high-quality standards, as it reduces the risk of defects and increases overall reliability.

Furthermore, the ability to produce complex geometries using advanced molds means that manufacturers can create parts that are not only aesthetically pleasing but also functionally superior, ensuring that products meet stringent performance requirements.

As the market for acetal copolymers continues to grow, projected to reach $848.2 million by 2030, manufacturers increasingly rely on injection molding for its efficiency and product quality. The integration of collaborative robots (cobots) in the injection molding process further enhances this efficiency. Cobots facilitate adaptive automation, allowing for quick adjustments in production settings, which supports the consistent output of quality products.

With AI-driven insights and human-robot collaboration, manufacturers can optimize their production lines, reduce downtime, and ultimately improve their competitive edge by reliably delivering high-quality products to market more swiftly.

Flexibility and Versatility: Adapting Injection Molding for Diverse Applications

Injection molding stands out as a premier manufacturing process due to its remarkable flexibility and versatility, allowing it to cater to a wide array of applications across various industries. According to a report by MarketsandMarkets, the global injection molding market is expected to reach approximately $340 billion by 2025, illustrating the growing demand for this technology. The ability to create complex geometries with precision makes injection molding an invaluable method for producing everything from automotive components to intricate household items.

One of the primary advantages of injection molding is its adaptability to different materials, including thermoplastics and thermosetting polymers. This capability enables manufacturers to switch materials based on their specific needs, such as durability, weight, or aesthetic qualities, without significant downtime. Furthermore, advancements in injection molding technology, such as multi-material and overmolding techniques, have expanded the range of products that can be manufactured. A study by Frost & Sullivan highlights that the integration of Industry 4.0 technologies into injection molding processes can improve production efficiency by up to 30%, underlining the method's progressive nature and suitability for diverse applications across sectors.

Related Posts

-

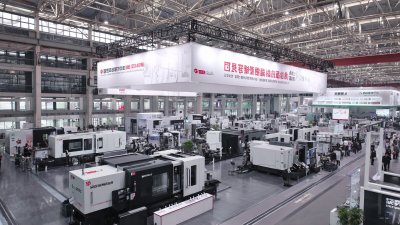

Exploring the Future of Injection Molding at the 138th Canton Fair 2025: Industry Insights and Growth Projections

-

Innovative Injection Moulding Process Examples That Drive Global Procurement Efficiency

-

Understanding Injection Molding Tooling Processes and Their Industry Impact

-

Injection Moulding Process Challenges That Every Global Buyer Should Know

-

Revolutionizing Manufacturing: The Future of Plastic Injection Molding Technologies

-

7 Essential Tips for Sourcing Plastic Parts Globally