Exploring the Versatility of PVC Sheets: Innovative Applications You Didn't Know About

In recent years, the versatility of PVC sheets has gained significant attention across various industries, showcasing innovative applications that extend far beyond traditional uses. According to a report by Grand View Research, the global market for PVC sheets is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028, driven by their lightweight, durable, and moisture-resistant properties. These sheets are increasingly being adopted in areas such as architecture, signage, and even medical applications, where their adaptability brings substantial benefits. As industries continue to seek cost-effective and reliable materials, it is essential to explore the myriad of ways PVC sheets can be utilized, revealing approaches and innovations that many professionals may not yet be aware of. This article delves into the extensive and sometimes surprising applications of PVC sheets, illustrating their integral role in modern manufacturing and design.

Innovative Uses of PVC Sheets in Eco-Friendly Construction Practices

PVC sheets have emerged as a transformative material in eco-friendly construction practices, bringing a remarkable combination of durability, flexibility, and sustainability to the industry. According to a report by the Global PVC Market Analysis, the demand for PVC in construction applications is expected to grow by 4.5% annually through 2025. This is largely attributed to its recyclability and energy efficiency compared to traditional materials. The use of PVC sheets in construction helps reduce waste as they can easily be repurposed for different applications, thereby minimizing the environmental impact.

Innovatively, PVC sheets are being utilized in various eco-friendly designs such as green roofs, thermal insulation panels, and even as cladding materials. A study by EcoBuild indicates that incorporating PVC in building envelopes can reduce energy consumption by up to 25%, demonstrating its significant role in promoting sustainable building practices. Furthermore, the lightweight nature of PVC sheets not only reduces transportation emissions but also allows for easier installation, making them an attractive option for modern architects and builders aiming to adhere to green construction standards.

Exploring the Versatility of PVC Sheets: Innovative Applications You Didn't Know About

| Application | Description | Eco-Friendly Aspects | Benefits |

|---|---|---|---|

| Wall Cladding | PVC sheets can be used as lightweight and durable wall coverings. | Sustainable material with low environmental impact. | Easy maintenance and a variety of colors. |

| Roofing | Used as an alternative roofing material with excellent insulation properties. | Reflects sunlight which helps in energy conservation. | Durability and longevity reduce the need for replacements. |

| Window Frames | PVC sheets are used in the manufacture of energy-efficient window frames. | Recyclable and helps to lower carbon footprint. | Improved insulation reduces heating and cooling costs. |

| Furniture | Innovative designs use PVC sheets for lightweight and waterproof furniture. | Made from recycled materials. | Durability and versatility in design. |

Harnessing PVC Sheets for Creative Interior Design Solutions

PVC sheets have emerged as a versatile medium for creative interior design solutions, offering an array of innovative applications that are often overlooked. These sheets not only serve practical purposes, such as durability and ease of maintenance, but also allow designers to push the boundaries of aesthetics. With their varied thicknesses, including options under 3mm and between 3mm to 5mm, PVC sheets can be tailored for specific design needs, whether it be for wall coverings, furniture finishes, or decorative elements.

The global market for PVC foam sheets is projected to grow significantly, indicating a rising trend in their adoption. The anticipated increase from $2.07 billion in 2023 to $3.2 billion by 2032 reflects a compound annual growth rate that underscores the growing recognition of PVC sheets in interior design. Their lightweight nature and versatility in finishes mean they can easily be integrated into both modern and traditional spaces, providing endless possibilities for designers to create unique, functional environments. This growing market highlights not just the material's practical uses but also its potential to inspire creativity in interior design.

Exploring PVC Sheets in the Manufacturing of Custom Packaging Solutions

PVC sheets have become increasingly popular in the manufacturing of custom packaging solutions, offering a blend of durability, flexibility, and cost-effectiveness. According to a report by Research and Markets, the global PVC packaging market is expected to grow significantly, reaching USD 76.84 billion by 2022, highlighting the surge in demand for materials like PVC in custom applications. This growth is driven by the material's ability to be easily molded and adapted, making it ideal for creating bespoke packaging that meets specific product requirements.

Additionally, the versatility of PVC sheets allows manufacturers to create innovative packaging designs that enhance product visibility while ensuring protection from external elements. The sheets can be printed on, shaped, and co-extruded, which opens up a world of possibilities for branding and product presentation. A study by Freedonia Group indicates that demand for sustainable packaging solutions is also pushing the use of PVC as it can be recycled, allowing companies to align with eco-friendly practices while still leveraging the material's unique properties. This makes PVC sheets not just a functional choice, but a strategic one for businesses looking to stand out in a saturated market.

Utilizing PVC Sheets for Water-Resistant Applications in Outdoor Furniture

PVC sheets have emerged as a game-changer in the outdoor furniture industry, especially with their remarkable water-resistant properties. According to a recent report by the American Society for Testing and Materials (ASTM), PVC materials show a water absorption rate of less than 0.1%, making them ideal for furniture exposed to the elements. This characteristic not only enhances durability but also ensures that outdoor furniture remains aesthetically pleasing over time, reducing the need for frequent maintenance or replacement.

PVC sheets have emerged as a game-changer in the outdoor furniture industry, especially with their remarkable water-resistant properties. According to a recent report by the American Society for Testing and Materials (ASTM), PVC materials show a water absorption rate of less than 0.1%, making them ideal for furniture exposed to the elements. This characteristic not only enhances durability but also ensures that outdoor furniture remains aesthetically pleasing over time, reducing the need for frequent maintenance or replacement.

When designing outdoor furniture, it’s essential to also consider aesthetics alongside functionality. Utilizing colored PVC sheets can provide vibrant options that resist fading, ensuring your pieces look new for years. Furthermore, manufacturers have discovered that combining PVC with other materials can result in lightweight yet sturdy furniture, appealing to modern consumers who seek both style and practicality.

Tips: For homeowners looking to invest in outdoor furniture, consider choosing pieces made with PVC sheets, as they offer superior resistance to water and UV rays. Additionally, pairing PVC with materials like aluminum can create a robust and fashionable furniture piece that is easy to move and maintain. Keep in mind that regular cleaning with mild soap and water will enhance the longevity of your outdoor furniture, allowing you to enjoy your investments year-round.

Expanding the Role of PVC Sheets in Health and Safety Equipment Production

PVC sheets have long been recognized for their versatility in various applications, but their role in the production of health and safety equipment is particularly noteworthy. According to a 2023 report by the Global PVC Association, the demand for PVC in the healthcare sector is projected to grow by 5% annually, driven by its superior durability, resistance to chemicals, and ease of sterilization. These properties make PVC sheets ideal for manufacturing protective barriers, medical equipment coverings, and even components in laboratory environments.

In addition to traditional uses, innovative applications of PVC sheets are emerging in the realm of personal protective equipment (PPE). Research conducted by the International Safety Equipment Association indicates a rising trend in the integration of PVC materials for safety vests, shield masks, and disposable gowns. The lightweight yet robust nature of PVC allows for improved comfort and mobility, essential in high-demand settings such as hospitals and emergency response units. Furthermore, the ability of PVC sheets to be recycled supports growing sustainability efforts within the healthcare sector, aligning with the industry's goal to reduce environmental impact while enhancing safety protocols.

Related Posts

-

Ultimate Guide to Sourcing PVC Sheets for Your Global Supply Chain Success

-

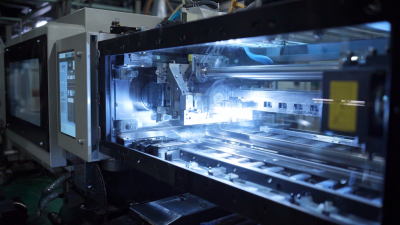

How to Choose the Right Injection Molding Materials for Your Project Success

-

Revolutionizing Manufacturing: The Future of Plastic Injection Molding Technologies

-

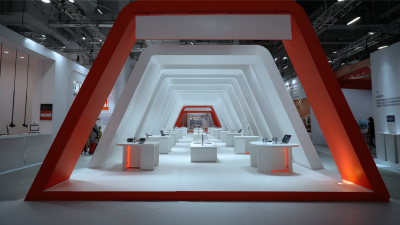

Exploring the Future of Plastic Angle Products at the 138th Canton Fair 2025 in China

-

Ultimate Guide to Selecting the Right Injection Molding Tooling for Your Business Needs

-

Exploring Trends in Injection Molding Materials at the 138th Canton Fair 2025