Why Dip-Molded Plastisol Caps Are a Go-To Solution for Industrial Protection

In industrial environments, every component matters—especially when it comes to protection. Whether you’re shipping parts, sealing assemblies, or enhancing safety, the right plastic cap can extend product life, prevent damage, and reduce maintenance costs.

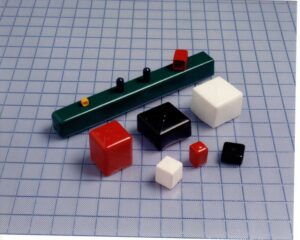

At Carlisle Plastics, we manufacture durable, flexible plastic caps using a process called dip molding, with plastisol as the base material. These plastisol caps are trusted across countless industries for their resilience, adaptability, and cost-effectiveness.

Below, we’ll highlight the top 7 industrial applications where our plastisol plastic caps make a measurable difference.

1. Thread and Pipe Protection

One of the most common uses for dip-molded plastic caps is protecting threads, fittings, and pipe ends during manufacturing, transport, and installation. Uncapped threads can easily become damaged, contaminated, or misaligned—causing major issues later in the process.

Our plastisol end caps form a snug, secure barrier that shields threads from dirt, moisture, vibration, and impact. Plus, they’re easy to apply and remove by hand, saving time on the shop floor or job site.

2. Electrical Shielding and Insulation

In electrical and electronics applications, dip-molded plastic caps serve as insulating sleeves or protective coverings for terminals, connectors, and wiring assemblies. Plastisol offers excellent dielectric properties and resists cracking under temperature fluctuations, making it ideal for insulating live parts.

We can tailor the durometer, wall thickness, and fit to suit a variety of voltage or load-bearing requirements. Whether you’re shielding delicate sensor leads or power connectors, plastisol plastic caps help prevent shorts and enhance operator safety.

3. Tool Handle Coatings and Grip Enhancement

For tools, levers, and hand-operated devices, plastisol dip-molded caps are often used to improve grip, comfort, and safety. These caps can be made with a soft-touch finish that provides anti-slip performance and absorbs shock during use.

Whether it’s pliers, cutting tools, or assembly fixtures, our custom plastic caps give tools a clean, professional look while improving ergonomics. They’re also resistant to oil, grease, and repeated handling—making them perfect for industrial and automotive environments.

4. Dust, Moisture, and Marine Barriers

Harsh environments like marine docks, outdoor installations, or construction zones can wreak havoc on exposed parts. Plastisol plastic caps act as tight-sealing barriers that prevent water, salt, dust, and debris from entering critical components.

These end caps are especially useful for sealing unused ports, conduit ends, or equipment during shipping and storage. Their resistance to UV radiation and extreme weather makes them ideal for long-term outdoor use.

5. Storm Panel Caps and Shutter Plugs

In coastal regions and hurricane-prone areas, aluminum storm panels are commonly used to protect homes and businesses. The sharp-edged studs or bolts used to secure these panels can pose a safety hazard—and that’s where plastisol caps come in.

Our plastic end caps are widely used as storm panel plugs to cover sharp threads and fasteners, reducing injury risks and giving a clean finished appearance. Their flexibility ensures easy installation, even on irregular hardware.

6. Color Coding and Inventory Management

Beyond physical protection, plastisol plastic caps are often used for visual identification and organization. In manufacturing and warehouse settings, color-coded caps help sort parts by size, type, or destination, simplifying inventory management and reducing errors.

We can produce custom color matches or use high-visibility shades to meet your operational needs. Whether you’re tracking production batches or labeling export parts, colored plastic caps offer a simple, effective solution.

7. Packaging and Shipping Protection

Many industries rely on plastisol end caps as a cost-effective way to protect finished goods during transport. Whether it’s a polished metal tube, an anodized extrusion, or a painted component, even a minor ding or scratch can result in product rejection. Corner protection during transport is another common usage for plastic caps.

Flexible plastic caps cushion parts against shock and vibration, act as dust and moisture seals, and give packaging a professional finish. Their low unit cost makes them a smart investment for any manufacturer looking to reduce damage-related returns or warranty claims.

Why Plastisol and Dip Molding Are Ideal for Industrial Applications

Why Plastisol and Dip Molding Are Ideal for Industrial Applications

So what makes plastisol dip molding the right choice for these demanding industrial uses?

- Durability: Plastisol withstands heavy use, impact, UV rays, and harsh chemicals.

- Flexibility: It stretches to fit snugly and bounces back into shape without cracking.

- Customization: With in-house tooling, we can match your exact size, shape, and color needs.

- Seamless Finish: Dip-molded caps are smooth and free of parting lines, reducing potential failure points.

- Cost-Effective: Especially for mid-sized and custom runs, dip molding is a more affordable option than injection molding.

With over 60 years of experience and a dedicated production team, Carlisle Plastics Company delivers industrial-grade plastic caps that meet the highest performance standards.

Need Plastisol Caps for Your Operation? Let’s Talk.

Whether you’re designing a new product or improving an existing process, our team can help you choose or create the right plastic cap for your application.

From OEMs to industrial suppliers, we support a wide range of industries with custom dip-molded plastisol caps designed to perform in tough environments.

Let us know what you need—your solution is just a conversation away.

Why Plastisol and Dip Molding Are Ideal for Industrial Applications

Why Plastisol and Dip Molding Are Ideal for Industrial Applications

What Are Custom Plastic Caps?

What Are Custom Plastic Caps? Why Custom Doesn’t Mean Complicated at Carlisle Plastics

Why Custom Doesn’t Mean Complicated at Carlisle Plastics

What Is Dip Molding?

What Is Dip Molding?

Why Choose Carlisle Plastics Company?

Why Choose Carlisle Plastics Company?