Plastisol uses a unique formulation process that suspends PVC particles in a plasticizer. The plastic is heated to 177 degrees Celsius, which dissolves both the PVC and the plasticizer. Next, the mixture is cooled to 60 degrees Celsius. This creates a plasticized product that remains permanently flexible due to the dissolved properties of the plastic. Often, this plastic is used for molding various plastic products, but it has a variety of other uses as well including dip coating.

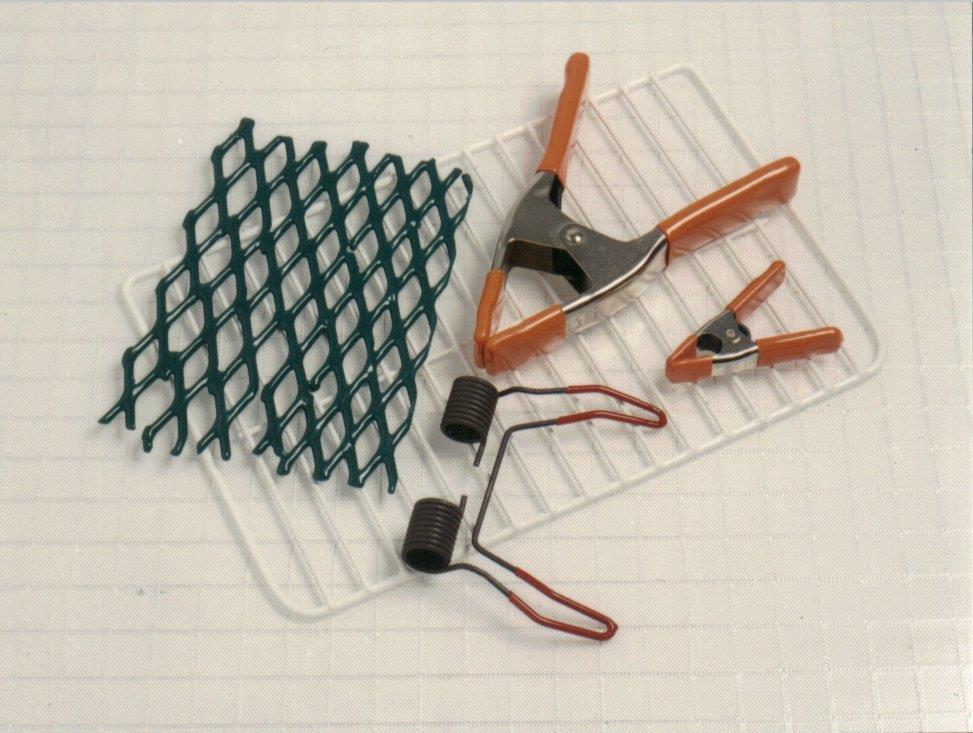

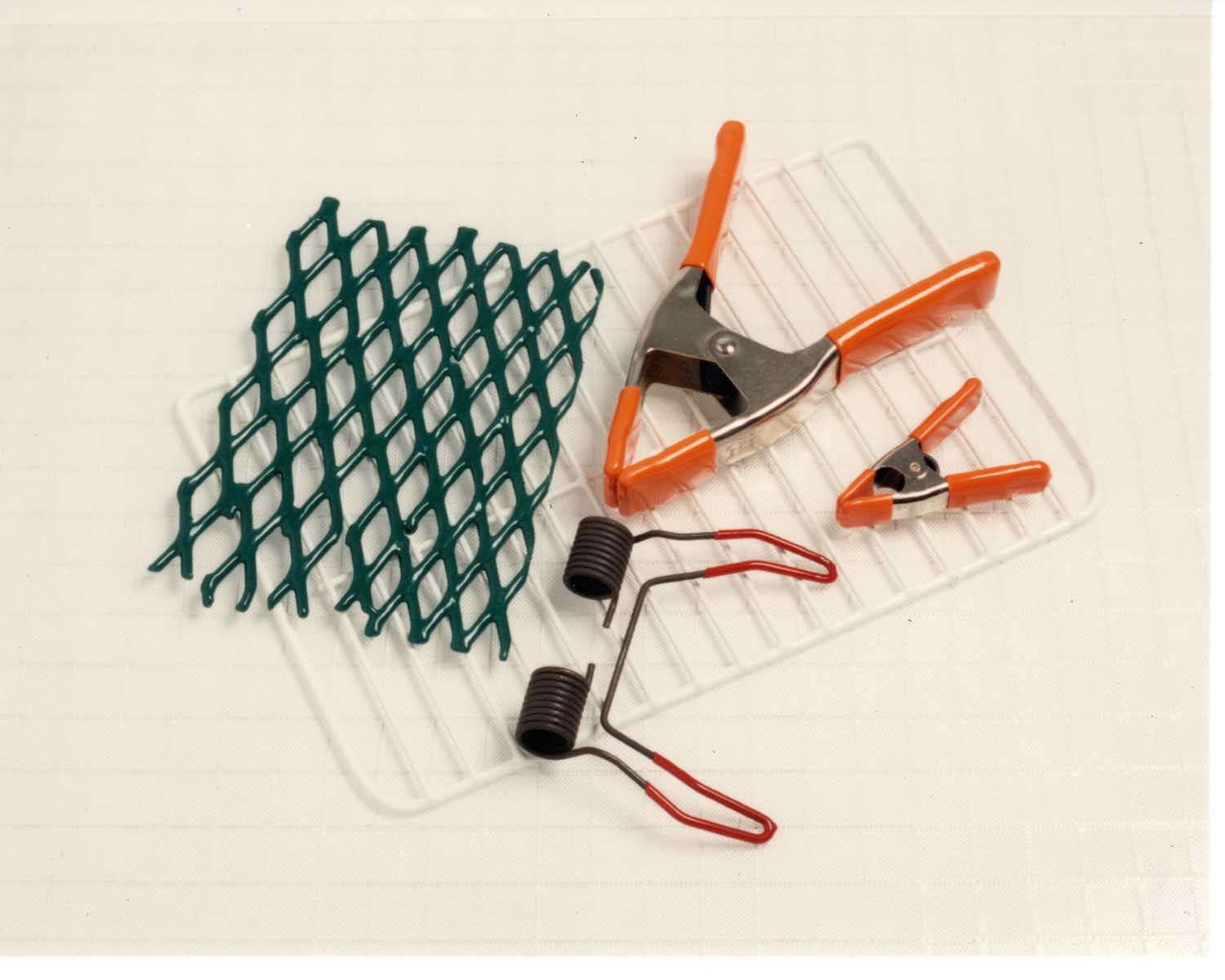

Plastisol is often used in the manufacturing of roof coatings, furniture coatings, screen printing, and textile ink. Plastisol is often used for dip molding, because it coats objects in a flexible coating that is both attractive and durable making it ideal for products such as plastic caps and end tips. Industries use plastisol coatings for a variety of tasks, such as coating tools, protecting surfaces, creating waterproof barriers, and protecting delicate parts from impact.

Surprisingly enough, many of the printed images on modern clothing is created from plastisol coatings melted into the fibers of the fabric. Plastisol is perfect for screen printing because the plastic soaks deep into the fibers of the fabric, allowing the image to stay in place longer. Plastisol will not dry on its own, but requires a curing process to harden the plastic. Plastisol-coated clothing must be cured in an oven before it can be sold in retail locations.

Another popular use for plastisol is as a material for slush molding. In slush molding, the plastisol is placed inside a metal mold, which is then spun rapidly to force the plastic to take on the shape of the mold. The mold is then heated and excess plastic is poured out. This creates flexible, hollow molds perfect for a variety of industrial and commercial uses.